Was a good try but I’m still finding that when I add pressure to the discharge side (even with the collection column and inlet of the corken under vac) it still flows to the inlet side.

Did you see what @BC9696 posted last week about the aluminum valve seals not sealing well and causing this exact issue?

He said he heard this from both ETS and Corken technical support.

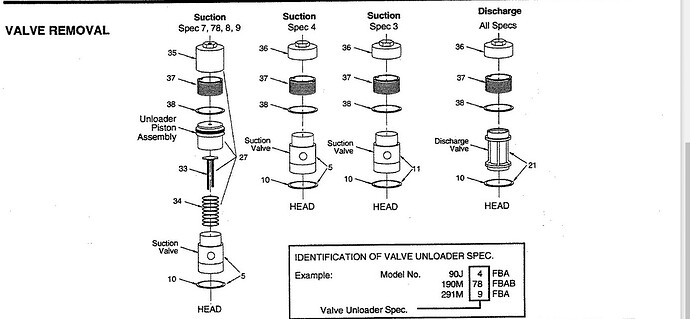

If you look under suction valve spec 3 below I believe he’s talking about gasket #10, which should be aluminum. If you either reused or didn’t really tighten down the valve body, this gasket could be very likely be your issue.

This is a great response and does make sense. I know they are aluminum, we did order and use brand spanking new ones and we tightened down on those valve bodies so much that the brand new gaskets have markings!

From what I’ve gathered I believe that the valves stopping flow while off is abnormal, and that it was happening on my Corken, which is abnormal. Then when we gave the valves a good scrub, pressure was able to flow from one side to the other while the corken is off (which is normal but I had never experienced it).

I have a call with a repair person today and will update any info I get.

this was essentially the answer that both Corken and the repair company gave me. Those seals wont be perfect. Bleeding from one side to the other is normal, we are good to run.

I am just slightly paranoid about safety. That you to all who contributed. Ill come back here with any repairs.issues/updates I have with our Corken.

Get some more hash in there…

leaking from inlet to outlet isnt a safety concern as long as the system is closed and sealed before and after the pump. Does the pump retain pressure overall? have you sprayed the pump down with soapy water to ensure it isnt leaking from anywhere? and f there is no bubbles does the pressure stay stable if you close off both sides of the pump?

Yes, Yes, and Yes!

Today we are up and running and I’ve been in the booth the whole time. Seems to be running a bit faster than I’m used to.

I’m Slightly embarrassed with the whole situation and am very thankful to have you goobers having my back when I need to think through things like this.

Heh, I used to work in the automotive industry and this reminds me of how automakers would have a production issue with a part, people would notice and complain but it’s too difficult/expensive to replace or fix and it’s not a safety issue so the company would just come out with a bulletin acknowledging it and calling it “normal”.

If you look at the design of the outlet valve, its just a basic seat and spring. It should only allow flow in one direction and only if the pressure on the seat side is greater than the spring side. In other words, the outlet valve should only allow flow if the pressure in the compression chamber is higher than the pressure in the outlet tubing.

That’s why it’s normal for pressure to flow freely from inlet to outlet with the pump off (because this pressurizes the compression chamber) but not “normal” for it to flow from outlet to inlet.

Plenty of other manufacturers don’t have this leakage problem and honestly I would be a little upset about this. We’re pumping flammable gas here.

I have used lots of other pumps/compressors that don’t have this issue, I think Corken just doesn’t want to come out and say “yes this is an acknowledged issue and we’re not fixing it because we don’t think it’s a big deal”.

Isn’t that what you removed to start this whole mess?

sounds like a faulty check valve. make sure you have them installed in proper locations. The check valves are fairly easy to replace.