Then where does “active” come into your CLS?

Yep. Some linked here

Tell is you can even manage -40

I would agree that sans pump, evaporation won’t get you there… however, if you treat it as a refrigeration cycle, then it’s not about how much solvent you’ve got, or how big the system is. More how well you can optimize and/or minimize (unwanted) heat exchange.

I still like to see understand the math (@Zack_illuminated?), because I’m almost certain it’s not as trivial as

because, over the range of pressures and temps we’re talking about, the thermophysical “constants” aren’t…

[insert graphic I imagine @Zack_illuminated will post ![]() ]

]

The pilfered graphic below suggests pulling the evaporator down to ~ 0.175 bar (~25in.Hg) will get you into the -40C range.

Which implies you could use a water cooled CMEPOL (ultimate vac 29+”) and make cold solvent by making hot water.

Maybe. Start here: Has Anyone Used Liquid Nitrogen to Chill columns, diamond miners, etc?

With appropriate metering, direct (controlled) cooling has certainly been explored by a number of folks. Others have just opened the valve and let her rip.

The leidenfrost effect will not work in your favor.

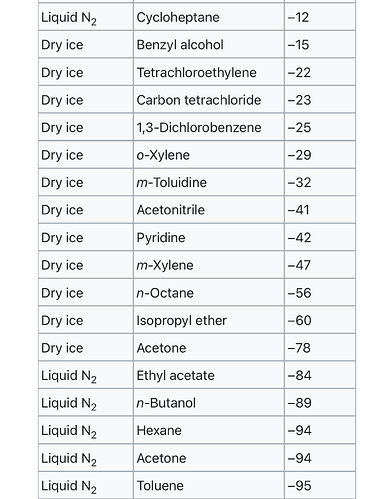

I’d looking into using a solvent + liq N2 cooling bath. I don’t see the right combo listed on the link given upthread, but it might exist…