Class went incredibly well, crystallizer slayed.

Travel to and from Toronto is a pita.

Basic summary of the tech:

After extraction off the biomass, the solution is deposited into the crystallizer where a specific saturation level is achieved, then the pressure and temperature variables are set.

Cold propane is added to the solution, simultaneously dropping the entire solution temperature (cold crash) while also changing the actual chemical solubility of the solution (propane “antisolvent”).

This is all done with the mixer spinning.

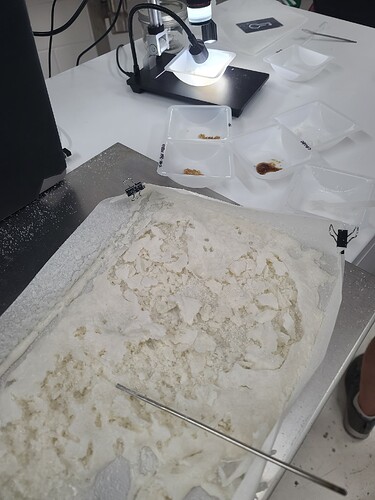

Here’s a pic of the THCa crashing out of the (nasty brown) solution within a couple minutes of the propane injection.

The solution is allowed to form a crystal matrix similar to that of a 7-11 slushie while mixing. Mixer is then stopped and solution can either be drained, or given another minute or 2 to allow the crystals to attach slightly, enabling the operator to drain the HTE and then wash with fresh solvent. Crystals can then either be drained, or dissolved back into warm solvent and process repeated to produce an even faster/cleaner crash.

Here’s the THCa after the HTE was drained and the remaining crystals washed once, then redissolved in just enough butane to evacuate the vessel

And here’s the reX in a miner

Next step for them is a paddle modification so that the reX can occur in the crystallizer, while agitating, to create larger loose crystals.