A simple, but no detail missing outline for my process below:

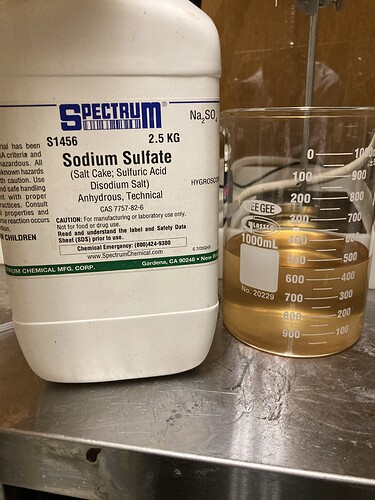

Dissolve 30grams CBD in 500ml DCM. Dry with sodium sulfate, filter through 1micron filter. Should be a clean, transparent solute with minor hues of yellow/perhaps yellow green. 1.902grams pTSA was used for this amount.

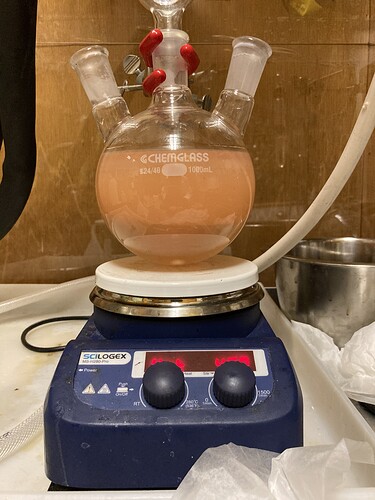

This is added to the boiling flask and setup for reflux. Its not necessary, but i use a three neck for most reactions to monitor inside temp as well as to allow for a stopper that i can pull out to use as a nitrogen flush port/or to add reagent through. So speaking of which, flush your reaction environment with N2/Ar. N2 is way more economical for this process.

Set condenser to 0-10c. Doesn’t really matter. Reflux for 2h 30min.

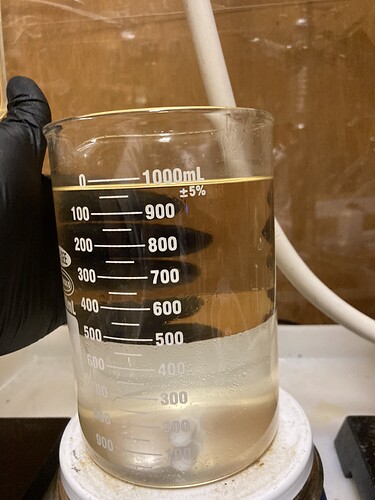

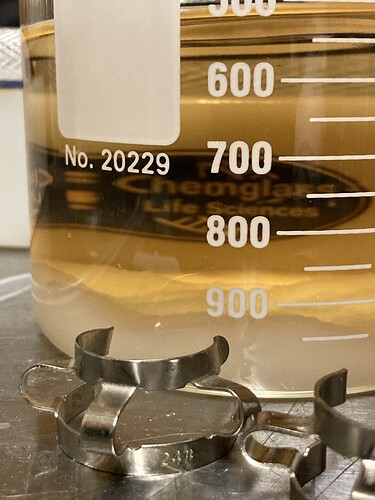

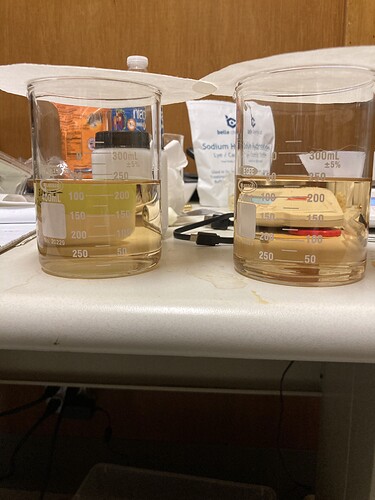

Once allotted time is up, neutralize with Sodium Bicarbonate using 1mol NaHC03:1mol pTSA. I do this by beaker on stir plate for ~15min. However long it takes to get to the clarity on picture 3. That picture is literally just right after a neutralization. Not any washes. I find the key to that clarity for me, is using deionized water.

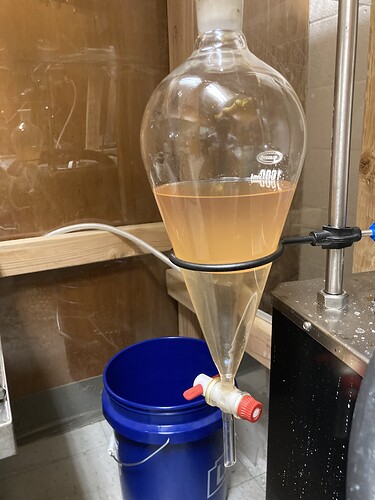

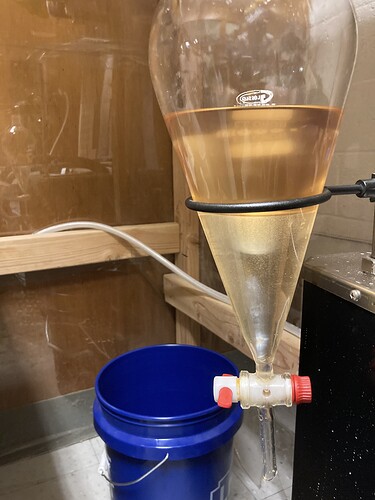

Once neutralized, separate the aqueous layer, do a brine wash(some people i think are saturating their water for brine washes, this is not necessary), then once more a D.I. Water wash. Dry with sodium sulfate, filter and evaporate. At this step, if you have followed traditional technique and tapped your heels three times you should have your 94%+ delta8 with low(1-5% D9).

Here’s where you will take your remaining residue, no solvent(or at least solvent evaporated before you add reagent, doesn’t have to be but guarantees strength of media), REFLUX under vacuum until you hit 150c INTERNAL TEMPERATURE. Add T-41 to boiling flask in a percentage of 20% by weight. (1000kg in the flask, 200grams media)

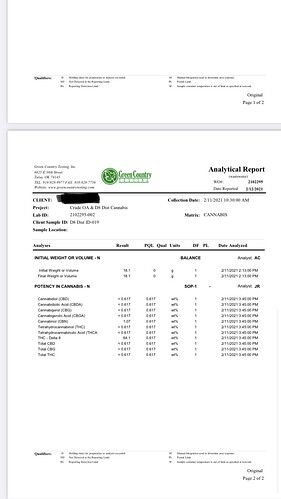

Doesnt matter what your mantle says, you may not be at that temp unless you have a probe inside your reaction flask telling you so. Once you hit the temp 150c. Set a timer for thirty minutes. Once your thirty minutes is up, kill vac, replace your reflux condenser with a distillation head and collection that beautiful bounty of non detect d9. The test results I’ve posted down below are a result of a process i did in a hurry, and I didn’t distill. I simply refluxed with T-41 for thirty minutes, let the residue cool to below 60c, added heptane to dissolve and then filtered with 20micron, 10micron and then 1 micron. Evaporated solvent and dropped it off at testing, hence the lower d8. Admittedly, this is the lowest test score I have ever gotten in d8. Finishing this process correctly by actually distilling you will achieve the product you want.

Now I already know there is going to be hate/doubt. I myself am skeptical of so so much in this industry. But please, to those experienced enough in the art and are traditionally trained like myself, even if you think you’ve tried this process before, just follow these instructions and let me know what results you get. You wont be let down. Pictures below:

This picture below is from a hexane reaction where the organic layer is on top, if you did a DCM reaction, the organic is on the bottom.

Oh and all these pictures are from the same reaction except picture three. They are all pictures from my hexane reaction, but are simply posted for visual reference to the OP. I will post Pictures of the process with Dichloromethane soon on a separate thread.

Sorry for the edits, I keep forgetting small details. Tsk tsk