@Pupparoo ![]()

![]() That definitely gives me bird feeder vibes

That definitely gives me bird feeder vibes

Nice cock!

The sambo creek mescalatore is pretty spendy for a single use plastic

@raghanded is the cock to prove that you are the one taking the picture and it’s not a stock photo?

So if it’s not a stock photo, it must be a cock photo….

It all makes sense now.

I mean, they do exist…

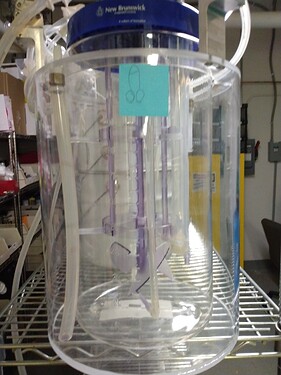

Should you add a big ultrasonic horn inside? No… but there are plastics used in food/bev production and pharma as well.

There’s pp tanks that plastic liners go into as well so you don’t have to throw the reactor away. I used those the bioprocess bags up to 200L in industry

Hey Nick,

We’d really love the chance to speak with you if we haven’t already. 25kg in a day is a walk in the park for The Osprey, and we have the ability to pull full melt from our machines all day long. Quality and quantity are both on the table.

You’re more than welcome to visit our lab in Denver, or we could even connect you with a local customer in your area if you wish. You can reach us at 316-308-7441 if you want to chat about your build!

Would love to hear from this person that actually owns an Osprey or uses an Osprey with this feedback! Genuinely, we get a ton of love on The Osprey and it’s ecosystem. We have dozens of customers who come back and buy their 2nd, 3rd, and 4th machines, which wouldn’t happen if they weren’t enjoying their experience. .

Where the Osprey really thrives is a high extraction value per dollar as well as very intentional design/extraction methodology. Our no shear impeller gently and thoroughly mixes, while the square shape ensures an even mixture rate throughout the water. We aren’t going to be the fanciest/most expensive machine, but we can guarantee you that simplicity brings an extremely high quality hash and less headaches/moving parts.

Our products are made with Simona plastics, some of the best in the world. As others have posted, these products are used throughout pharma and food service applications. The notion that our products are single-use is misguided at best. We manufacture stainless and titanium reactors for other industries but PPH is far superior in this application.

Round systems have some fatal flaws that need to be overcome, yet none do. I have several YouTube videos on this topic. Boring AF, but it’s the truth.

In the Mesclatore, abrasion is not an issue due to design. After a dozen or so tons processed on our oldest trolley, you will not find this issue. Our system has a bag where the flower never touches the tank wall (not that it matters). The bag hoists out of the tank and a bottom zipper makes cleanup a breeze.

When looking for a system, do some due diligence. Get some real opinions, the good, and the bad. You do your company a disservice by just taking one person’s biased opinion.

Here are some questions you may want to ask. Never get this data from a manufacturer, salesperson, or a biased “advocate.”

- How long have you had your machine and how often have you used it? (Gives perspective on overall proficiency with the system.)

- Do you keep production logs of your runs? (Is the data meaningful or just an opinion?)

- How many pounds can you wash per batch and what is the yield? (Do manufacturer claims differ?)

- Have you ever had overloading problems? (Why would this be happening?)

- What were the expected yields and do you have statistically representative data to determine how much yield was lost? (How much will this cost my operation in yield loss?)

- What does the cleanup look like? How long does it take to clean the machine? (If I’m gonna have to clean this thing, am I up to the task?)

- How many batches can you really wash in a day and how long does it take to reset each batch? (Will the workflow interfere with my work shift? Will I even have time to do more than a batch a day?)

- How many people does it really take to operate the machine and what does the workflow look like? (How much money will my labor costs be if I need several employees?)

- How are the ergonomics of the system and how hard is it to go through the paces? (Is this backbreaking work needless? Can someone get hurt?)

- What do you like and dislike about the machine? (Is this person sugarcoating things? Why?)

- What does the quality look like? (Dig deep here as this is important. What’s his SOP and what does he call “quality”)

If anyone wants to see the Mesclatore in action, lemme know.