I am using an Apeks 20Lx20L 2,000 max PSI and want to extract raw material for THCa with as minimal decarbing as possible. What parameters should I use? Ideally looking to make shatter, crumble and CBD:THCa tincture with the material.

at 2000psi you prob wont pull a ton at room temp, but a lotta times those co2 rigs will heat up on their own. cheebach’s conditions look good.

but something to understand is that if it takes hours and hours to extract at say 30c, you may have more decarb than you do at say 50c if the 50c extraction is complete in say 1/4 the time. low and slow might actually give you more decarb because of time as a factor.

last co2 rig i ran was a waters and id blast shit out of it at 60c 300bar and itd come out still more thca than thc. the dwell time at heat is much lower at those conditions.

also you do get a gradient on these co2 extractors of thc:thca, thc is more soluble in co2 than its acidic counterpart. dont let this phenomenon be a red herring in your r&d!

i would recommend doing runs at various pressure and temperatures, and if you arent fully satisifed, perhaps a gradient (ramp your temp or pressure through your extraction) in short play with the thing!

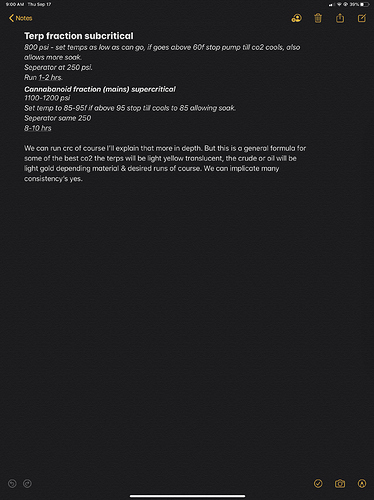

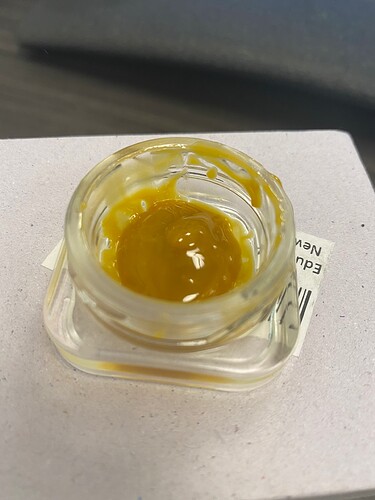

Been doing R&D runs and got an interesting result.

Run shut down due to a clog but the yield was powder. Mixed a little back into raw terps and voila

Unwinterized CO2 batter. It’s chunky, lol, but the winterized final product should be better color and smooth. Not bad for a cured batter.

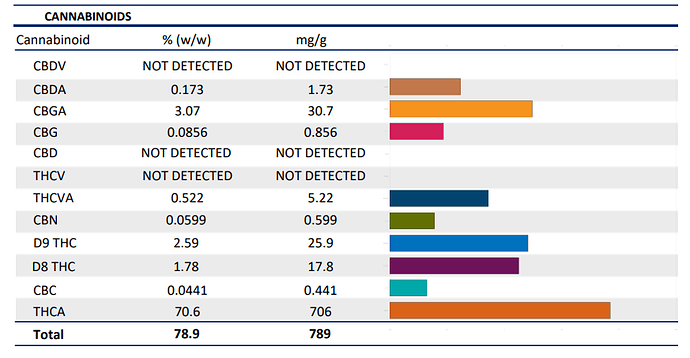

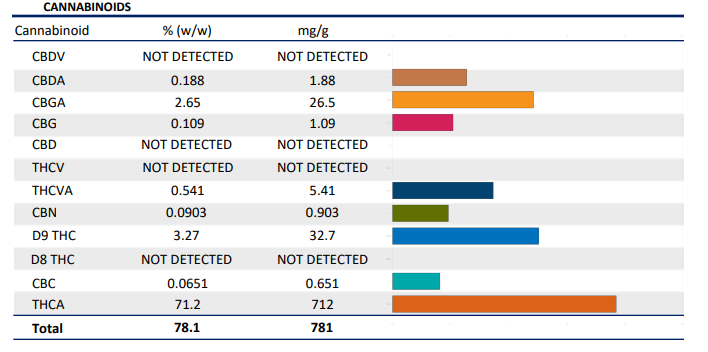

Interesting d8 result

Any guess how that came to be?

(Also edit lol what’s up with the scale on those bars on first look it looked like d8 was half as high as d9Thca at 70%)

No clue, guessing the lab fucked up. We grew the flower and it’s been sitting in our vault.

That’s pretty solid work there…

Above 70% in a CO2 crude is incredible.

Machine to jar is a pretty slick MO

What kind of efficiency are you getting for cannabinoid removal?

We lost our internal QC chemist so I don’t have numbers yet. Next on my list is shipping off the raffinate/biomass for testing. I have mentioned to corporate that they should let me use the lab since we have 2 HPLCs and a Headspace/GC sitting idle.

I sent out the crude first because honestly I had no idea what the unknown % was going to be. Going to mix a few batches as-is with terps and make some batters, and send those off for testing as well. Those will then go to employees for $1/gram for reviews.

If all goes well we will push forward for a product launch.

I should mention we retain the dewax cut which gets winterized and will go to a recrystallization to give us some sugars or maybe diamonds.

You can definitely extract THC-A at near critical conditions. Keeping the system cool enough is the hard part. Run your separator pressure as high as you can to reduce the likelihood of flooding the separator.

That’s some clean looking THCa. We’re still pulling some waxes but we don’t have to scrape the bowl quite that hard…