I have a 1 lb closed loop crc system from extractor solutions. My material is and always has been machine trimmed (very fine, yield 20-25%) I have ran luster max for my crc powder straight onto the sintered 3” 1um micron disc (no paper) I could get 30 or so runs out of that disc before clogging issues would appear, and I would replace. I have bought 3 discs over the lifetime of my machine. After speaking with @Killa12345 on the phone, he suggested running prefilters. I purchased two tri clamp filter plates from his website. I am using 25um filter paper purchased from extractor solutions online. On my very first run with this method, with a brand new sintered disc, it clogged immediately. No butane reached the collection chamber. I relieved pressure and disassembled my filter plates while the column was full, and discovered that there was roughly a half ounce of bho in between my first filter plate and the second plate. The solution did not penetrate the filter paper on the second plate, and did not reach my crc powder.

I have done dozens of runs with the powder directly on the plate, but I started getting clogs after 4 runs on a new sintered disc, so I started adding the pre filters but am still getting clogs.

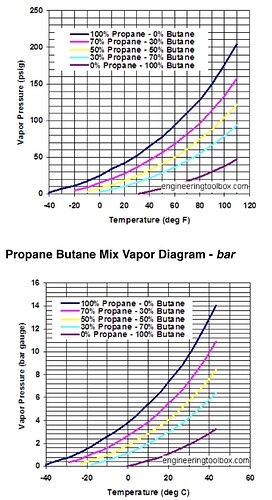

I am not using nitrogen assist, I have always had very good experiences with dry ice and hot water to manipulate the pressure in the tank.

1 Like

Just to clarify, this was oil and not crashed out THCa?

How much pressure are you able to achieve?

Did the collection build any pressure?

If you’re running straight n-Butane, you may not be getting enough pressure with hot water alone. Are you heating a separate tank for a vapor push?

If you’re dealing with fast crash or Medusa issues, adding additional pre filters may work against you due to the Joule-Thomson effect.

You’d be better off building smaller CRC’s and swapping each run, than trying to pump as much as you can through one, especially if you’re running any type of quality material.

3 Likes

I’d recommend grabbing an ultrasonic cleaner for your discs. You should also be filtering down to .22µm.

4 Likes

25 micron filter will slow things down a lot.

What was your pressure without the 25 micron filter in place? What was your pressure after? If you don’t know - its hard to know how much more you will need.

Once upon a time - I was running right around 8 PSI. I added and changed some things - 8 PSI was no longer enough to move things through. I had to kick it up more than double. So I decided my change was no good because I couldn’t consistently run higher without adding N2 assist.

Once upon a time - I had a friend with a venturi pump that he was just sure was not working. I asked him what was his PSI - which was down around 15psi - to get that membrane to flip, it needed to be closer to 80-90psi. And then he was cooking and pulling vaccum like a champ.

I think you are having a pressure issue - based on the information you have provided. Which can also be impacted by the purity/type of your solvent - and the temperature of your hot water bath.

Get that figured out and I bet your clog will go away - perhaps the filter is working as intended. There are also SLOW and FAST filters out there. And the slow ones are SLOW. That was speed of gravity back in the day, but pressure still matters there as well.

Let us know what that pressure looks like. And if this helps.

2 Likes

If no butane reached your collection, but you had finished concentrate in your plates you likely recovered the solvent before it could reach the collection. Was the column and/or crc still full of solvent?

1 Like