Basic bitch tampon tek depth filter. Pic stolen from a friend. 4"tampon

@Ghostyy420 I’ve only been doing this for like 3.5 months. Crc is what I learned immediately after doing crude runs and it’s been a bitxhin time. I didn’t realize how clogged my discs were until I picked up an ultrasonic and cleaning powder from harbor freight. Went from taking 2h for one column to 45 min.

does alconox dissove clays somehow?

Then it’s user error. My guess is your ring isn’t tight enough.

@Hansel yes. That’s how it came when we bought it from extraction tek solutions. 5um disc on top of the column and 1um disc on the bottom the column.

That’s a problem…

That makes your 1um (and papers you said that are on it) take all the filtration “load”

You want your filtration staged down to your 1 micron sintered disc

Powders-20-10-5-1

Powders

20 is the coffee filter in plate

10 is your paper in plate

5 micron disc

1 micron disc

Hope this helps.

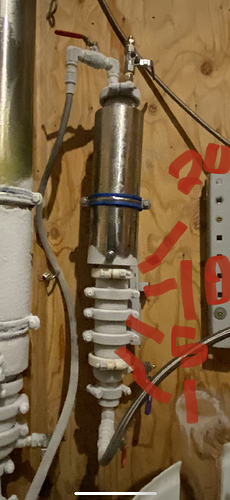

Ultra advanced tampon tek.

6 layers of staged felt in between filter plates, held in place by a fancy nut with OD threads…and a square drive spanner to tighten it down.

![20201021_175448|375x500]Are those off the shelf parts or where can I get one @TwistedStill?

Me likey this

Off my shelf…in my shed. Machined from stock…by me.

You gonna make some for the fam?

I’m about to quite my job, where I currently have access to the machines I use. I have steel building sitting in the clearing it’s going to be built in. Once its built…I’ll have machines again…

But until I quit…if I can make a few…why not. I was finishing up some Ti 6al 4v or whatever it is…I can never remember…baffles for an old project. Gotta finish what I’ve started first.

Ive used felt a long time but the w1 powder went through 1 um felt, My rings are as tight as can be. I cant even get the .5 micron felt in because its slightly thicker. I guess its possible I messed up because the top filter did seem to be blown out- probaly from nitrogen testing. and then under vac i couldve pulled powder through the crc bypass valves and hoses. i have a 1 micron sintered on top of collection and a .5 strapped on the collection stub so the oil is clean but I have a feeling I had channeling. The oil is an acceptable color but doest look white or clear like some crc.

@Hansel I’ll give that a shot. I appreciate all the tips. This has been very educational.

I will note, I do not put powders on the felt. I still use paper filters staged above, and am able to run the same felt for a while as long as I do my part. Or…fuck it…its felt and cheap. No slowed production due to a clogged disc.

I think u guys are missing the main point!

PREFILTERS , PREFILTERS PREFILTERS

30+ runs still no powders on disk

2 tri clamp paper filters a extras plate and rings to make it a double filter(2 plates , 4x filter paper in all and I always use 2 papers to make sure the rings seal tight)…then a felt depth filter then my disk

I havent washed my disk once and I have two disk…a 5um and 1um…some might say it’s a lil overboard but o well