@cyclopath

EDIT: I just realized you want to remove rust and passivate inside the jacket. My bad, I thought you wanted to passivate the tank interior. In that case, ignore my recommendations of a spray ball and CIP cart, lol.

I would use clean-in-place recirculation and take the lead from brewers. I have done this type of passivating innumerable times.

I recommond Birko as a passivation chemical supplier for nitric acid and oxider, or Madison Chemical for nitric acid. I have used them for a long time in various industries.

The following info is from a few resources:

If you can temporarily install a tri-clamp spray ball inside your vessels, that’s the best option. Otherwise, you’ll need more solution - enough to fill your vessels/path. You must also keep the solution hot, around 130-150’F, for up to 30 minutes. If you’re using recirculation, and don’t have a way to keep the solutions hot, installing an SS exchanger inline and using hot tap water is one way to heat the solution, but ia CIP cart would be better for tighter temp control.

However, a DIY CIP cart may be a good option because CIP carts can range from $5K to $9K for 20-30 gallons and you’re so good at building stuff. You can build one using two SS vessels, SS tubing, SS immersion heating elements, a pump (strong if you’re using a spray ball), and a PID. Check out Electric Brewing Supply and The Electric Brewery for parts and ideas.

Passivatvaiton of stainless steel requires a minimum of 10.5-12% chromium in the metal because oxygen combines with chromium to create a film of chromium oxide on the surface. Traditionally, nitric acid is used to passivate as a single-step process because it dissolves rust and trace minerals on the surface of the SS, and it’s a strong oxidizer. After the metal surface has dried, the chromium oxide layer forms under ambient oxygen over 24 hours.

Citric acid is sometimes used instead of nitric acid. However, unlike nitric acid, citric acid doesn’t passivate because it’s not an oxidizer. So it cannot oxidize the chromium automatically, which happens when you passivate. After running citric acid and allowing the surface to dry, the layer of chromium oxide will form over time (a few days?) from contact with air through natural oxidation, but it’s not optimized for passivation.

In both cases, with nitric acid and citric acid, the vessels/system can’t be used until the chromium oxide layer is formed after passivation. Meaning the equipment is out of commission for 24 hours with nitric and a few days(?) with citric. However, immediately following the acid passivation step with a non-caustic phosphate-silicate oxidizer instantly forms the chromium oxide layer, so the equipment is ready after rinsing.

But, according to Dana Johnson, Technical Director at Birko and a well-known and respected source of passivation information, “Acid cleaning and drying to form the Cr203 layer no longer work as well as they once did and create a condition called “flash rusting” (iron deposit), especially around welds.” Flash rusting is common after traditional passivation due to increased CO2 in the air (I’m guessing), especially at welds, because steel corrodes if a layer of chromium oxide does not protect the free iron from carbon steel.

For passivation, Birko recommends acid passivation immediately followed by a non-caustic oxidizer step (to form the chromium oxide layer) and rinsing. According to Dana Jonhson:

Remember, the aforementioned acid drained but not rinsed and immediately followed by noncaustic, oxygenated, alkaline cleaner method of passivation is known to metallurgists as a phosphate/silicate conversion coating, and should not be confused with the traditional high nitric acid method, which is drained but not rinsed and then followed by a 24-hour air dry to form a chromium oxide layer on the metal.

As soon as the alkaline detergent is fully rinsed away, the metal is passivated and can be put into service immediately if needed. This is simply because the conversion coating occurs as soon as the acidified metal surface comes into contact with the oxygenated, phosphate- and silicate-containing alkaline detergent.

Notes:

- Repassivate every 3-6 months.

- If your rust is extensive and heavy, citric acid should be used as the initial step to remove rust through chelation. If it’s just light rust, you can skip the citric acid step because nitric acid will remove rust.

Method:

- The vessels/system should be clean before you start. In brewery lingo, “soil” refers to residue from the brewing process on the SS surface. But our vessels should be clean, so we can ignore the cleaning steps to remove soil.

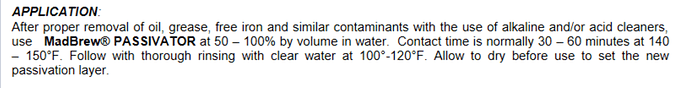

- To remove heavy rust, add 57 grams of citric acid per gallon of water, maintaining a solution temp of 120-130° F, and CIP (recirculate) for 15-30 minutes.

- Rinse well

- Use a 25-40% nitric acid product following mfg directions. Typically, prepare a solution with pH <1.5, maintaining a solution temp of 130-140° F (not hotter), and CIP (recirculate) for 30 minutes.

- Drain, but don’t rinse.

- Immediately follow with a mixture of sodium percarbonate, sodium metasilicate, and phosphate following mfg directions. Typically, 57 grams per gallon, maintaining a solution temp of 120-140° F, and CIP (recirculate) for 15-30.

- Follow with a thorough rinsing with purified water at 100°-120°F until pH is neutral.

For more info specific to your situation: contact Dana Johnson at Birko (he’s very informative and happy to talk):

DJohnson@birkocorp.com or (303) 289-1090.

Read more here:

Protecting Your Stainless Steel: Passivation for Brewery Equipment (by Dana Johnson; a great white paper)

Passivation of Stainless Steel (from M.G. Newell company)