Do you have the same issues with hexane?

Weld it, for less than 8k.

Pics!

I don’t use hexane but I imagine it could come up the same way (usually when the light phase has a bunch of shit dissolved in it and the heavy does not).

I will certainly be putting up pics when I get it disassembled

A man after my own heart-

“Oooh new toy- I can’t wait to tear it apart and cannibalize!”

Like Sid from Toy story.

Super excited to follow along! I do a lot of alkane to meoh lle’s too.

What have been the results to your testing? What have you tested?

THC, CBD, Water (brine, low ph, high ph, netural), Ethanol, Methanol, Heptane, Hexane …

I’ll be totally honest, this thing has been sitting on a shelf in the lab for ever now and I just haven’t had time to get it fired up and running. I’m literally ashamed lol. I will say that we tried gravity feeding it and yeah, that dog don’t hunt. Got some peristaltic pumps for it but haven’t fired it up since they came in

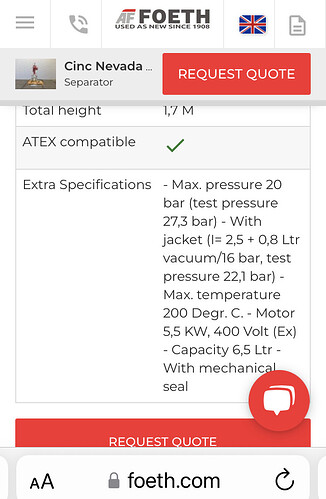

Cool tech, never understood it until I looked up that company CINC.

I had a small one for awhile. It worked with pentane, but was finicky. I prefer a disc stack because you don’t have to vary the speed for good separation.

How well is it on LLE

Of say salt water / alkane/canabinoids ?

I’m curious as well. I’ve done a lot of LLEs in my time and I’d love to make it a continuous process

It was ok. Not impressive. Once i found the right weir, flow rate and motor speed, it could run continuously. It’s more of a scalpel than a hammer. After using a disc disk and agitated reactor, I’ll never go back to a counter-current centrifuge.

What’s your favorite disk fuge ?

Alfa laval ?

I’ve had limited experience with Alfa Lavel but it was a very solid piece of equipment. It was able to handle some pretty solid organic/aq. LLE separations significantly faster than the tried and true mix in a large reactor and let separate naturally over time.

The good thing of countercurrent at least how I vision it is that all washes can be done in one flow 4 units chained

With different water currents entering

I ll need to contemplate this with a disk fuge

If you don’t need heavy agitation in your LLE - and most operations in this industry don’t seem to - it’s not all that difficult to set up a reasonably continuous semi-batch process with a tall column, some sight glasses, and some gear pumps/valves.

Hmm trying to get a picture of what you mean

But this I asume is yust a way to get faster separation of a singel batch

My favorite is one that is cheap, clean and works. We’ve gotten all the ones we tested to work. Haven’t needed to use a solid discharge unit yet, but they seem dope.

You can do multiple stages with disc stacks too. I’ve run them in batch or continuous processes. However, when you can run 35kg an hour, you don’t need multiple stages in most cases. 2 passes is still over 15kg an hour.