Heat gun for drying in a hurry

its probably your starting material or running temp, try freezing all your starting material columns before blasting.

huh, really? I have never had a problem getting the alconox out with soaking and flushing. Are you running one of our filters?

We chill our material and solvent to at least -40C

I got one from N.o.boler

can you test the ph of the runoff compared to your wash water?How are you determining that the alconox is still present? Can you run the “contaminated” filter with some more biomass without the celite in the filter?

If its the same color you’ve got a material problem.

I should have taken pictures but:

-

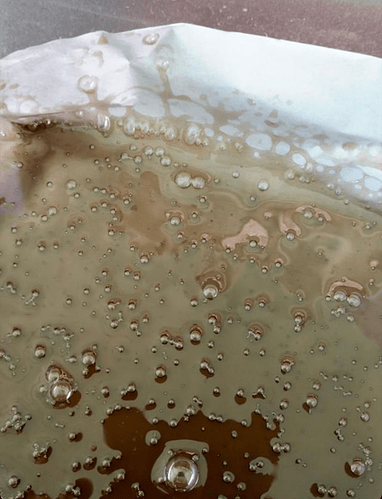

after pushing water and nitrogen thru the filter I can still see some bubbles coming out of the bottom around the edges

-

I took some un filtered ethanol/bho solution and evaporated off the ethanol then put it in the oven at 200F. When the oil reached that temp it stayed golden. When I do the same to the filtered solution it turns almost black and gets a funny smell.

-

I put an even amount of the unfiltered solution into 4 jars on a hot plate: 1 jar with just solution, 1 jar with solution and celite, 1 jar with ethanol and celite, and one jar with a drop of alconox and solution. When the ethanol evaporated off and the jars reached 200f the jar with alconox and solution turned dark and got a funny smell just like the filtered solution while the others remained golden

-

I packed the filter with T-5, silica, magnesol and T-41 with no celite and got the same results

What else do you think it could be?

I’m thinking either:

- residual alconox

- 1 micron filter is catching something from the tap water that is not being filtered out by the distilled water

- grease or something from the manufacturing process

- something in the extract

I’ll do some more tests tomorrow

the alconox should be leaving the surface clean of greases and minerals, the distilled water wash wouldn’t introduce any minerals or contaminates. That’s pretty standard practice in all labs for cleaning glassware, even glassware with fritted disks can be cleaned like that.With enough water and contact time even concentrated regions of the alconox will diffuse into the surrounding water and become more dilute. If you were able to get alconox cleaner into all the nooks and cranny’s of the filter you should be able to remove it as well.I regualry wash my sintered disk filters just like I described and have not seen any issues with the extract produced. Is anyone else seeing this issue?How many microns is your filter just out of curiosity?

The filter is 1 micron. I am going to put the solution thru a a different filters with no media and see if I get the same results.

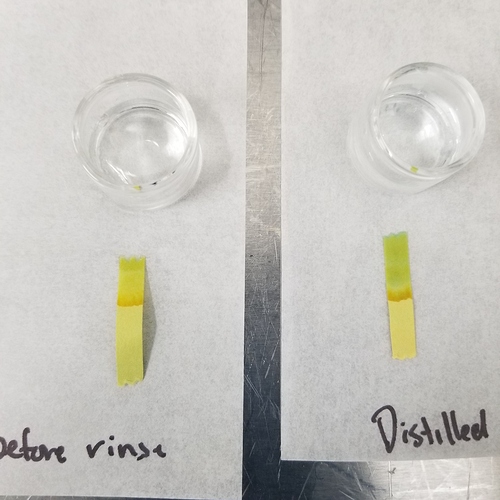

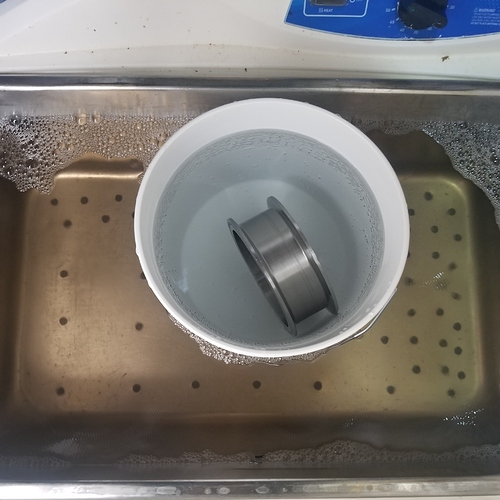

I put the filter thru the same cleaning procedure as described above another time. Afterwards I put the filter in a container, filled it with distilled water and put the container in the sonicator. I took samples of the distilled water before and after placing it in the sonicator. I only have test strips available at the moment however they are indicating that there is still something with a high PH in the filter. I’m going to keep cycling in fresh distilled water until it seems there is no change in PH

The left side is the before sample and left is after

*right side is after

I am having the same problem, and I am NOT using alconox. I believe it is the celite causing the issue. The color of my finished product is almost exactly like yours. I’m quite certain it is not a material quality issue as I ran a pass without the CRC and it came out a nice Amber as it normally does. I also believe it has something to do with the heat applied in the reaction vessel when reclaiming the gas. The solvent entering the reaction vessel is as clear as water, but as the boiling of the gas occurs the liquid begins to turn gray/brown. It is still quite clear but has color. I will temp the process again this week and post results

Soxhlet can I confirm that you are NOT using celite in your CRC? I will attempt the same process today that I have in the past but less the celite. 200g of silica on top of 200g of t5 clay per 1lb biomass. This will be packed and filtered through a sintered disc as well as a number of quantitative filter papers.

We dont use celite. Just the stuff from the original tek.

Hey @Alchemy_extraction,

I’m running into a similar issue as you. The only commonality I’m finding between my experiences, yours, and @moldynug is that we’re all using T-5. I noticed something similar with my run, where as it reduced it got darker and darker…

My hunch is that the T-5 is somehow making it through my 1um filter and slowly contaminating my extract as I recover. So it’s a small amount of T-5 relative to butane initially, but as one recovers, the T-5 comprises an ever increasing ratio of the product, and as a consequence it darkens it to a lighter brown or grey, depending on how effective your scrub is to begin with (i.e. super effective, no plant pigments, GREY | Not so effective, slight presence of plant pigments, LIGHT BROWN).

I attempted to troubleshoot this today by utilizing three filters rather than one. My thought process was that by using three filters instead of one, I could seal the outer edges of my CRC column more effectively, forcing more of the material through the filter rather than around. Unfortunately I noticed upon charging my column with cold butane I still had silica coming through, no T-5. I’m going to attempt to extract some material again, and see if the additional filters and slower charge/extraction will eliminate the darkening of my product upon recovery.

As a note though, I’m not presently using a sintered disk, so perhaps this could be part of it? I figured that with the 1um filter, I shouldn’t need anything else beyond a few screens to keep maco-particles and the like out…

Can you take some t-5 and mix it directly into the extract you are trying to filter and see if you get the same results?

I had oil get darker as it was reduced with no t-5 in the mix as well, only celite.

I am doing a side by side test right now.

Same solution, different contaminants. I’m putting them on a hot plate. I’ll report back once they reduce.

Anyone tried bvv’s t1?

I have used almost every mixture of powders eccept b80 and i have nvr had this issue, even when i had warm runs