that doesn’t really answer the questions I asked, but I appreciate the attempt.

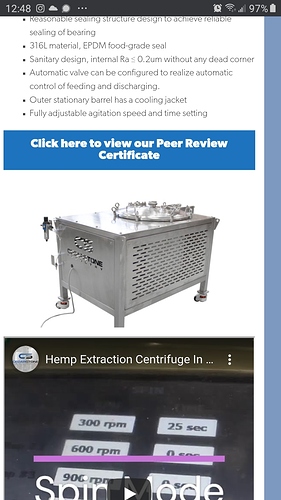

there are some fuges used for this purpose that have physical brakes.

The Bock/NSEP is one example. I can point you at others as well. Most however, rely on the motor and/or a set of braking resistors (comes with free toaster oven!).

The motor can only take so much load. same with the resistors. how much momentum the spinning load has, divided by the maximum load the “brakes” (motor and/or resistors) can handle, determine how long it takes to spin down.

presumably a panic stop (hitting the big red “OMFG” button) will give a decent approximation for the “absolute fastest we can stop this thing”.

Which I have seen take several minutes on various machines.

the time to stop when the panic button is hit should also be a decent approximation for how quickly the machine can be bought up to speed.

Assuming the braking sequence has been programmed correctly (which has not always been my experience direct from the OEM).

Strategically adding more mass to the rotor in the correct locations makes it less susceptible to misbalance conditions, but more rotating mass also means longer spin up and spin down. so there is a compromise that needs to be found.

I suspect you’ve got a typo here… and “for” should be replaced with “over” or “in”.

I’d also be willing to bet you can’t get from zero to 1500rpm in 15 seconds. or even 50 seconds.

If you talk to your engineer again, they should explain that what your VFD is doing is ramping the “current” up over 15 seconds. once at max current, you’re at max acceleration.

were I to guess, I’d say you then need to apply that max current for at least another 100 seconds to hit max speed…

the point is, I don’t want to have to guess.

either about how/where time can be shaved in your extraction cycle, or where the drips that are inevitable with your (standard in this industry) lid & seal design actually end up in day-to-day use.

Edit: think about it…same energy requirements for spin up and down. just applied differently. if you could spin it up in 15 seconds, how fast could you slow it down using the same motor? so where does 3 min come from? why would it take longer than spinning the machine up?