Tha is indeed the case. I mean, I have been enquiring/trying to guess the solvents the facility used to recrystilize the isolate in for quite a while now.

I wouldn’t be telling my full story here - but my first ever chemistry equipment purchased was an HPLC. So my interest in column chromatography merely arises from me being interested in the fundamental processes that happen inside my machine. And yes, I have tried

As it is an HPLC, and as there are no other chromatography machines for miles around me (GC with headspace would be nice) - I was trying for quite a while to guess the residual solvent used based on its physical properties. My HPLC was unable to give me an answer, till the very end I was thinking it was some isomer of xylene.

And I have not asked anything that google/chatGPT would be able to help me with. Neither I have asked what purification by recrystallization is. I was merely thinking that you guys have been at my stage years ago, and perhaps have a technique other than those books/google/AI can help me with. Or give me a new direction I could try.

Perhaps I would have been better asking “how to reduce loss to mother liquor during the process”, “what interesting solvent ratios I could try” or “why rotevaping at proper temperature/low enough vacuum doesn’t remove the residual toluene”.

The willingness to learn the upstream and downstream processes is exactly why I am here.

As if commercial conversion was my primary point of interest - I would just stick to what I have, without taking the extra effort to learn.

I have had yields above 90% on quite a few different reagents/solvents. But there were a dozen others which I attempted which gave me nothing but the satisfaction of trying them out, wondering why i have received different results to those published.

The toluene/ptsa at refluxing for 48hts alone I have tried at least 3 times at various conditions, and I am still wondering why the results I get are very far from those described in the papers.

But it is reading, testing, thinking, trying and testing again - this is how I learn.

I apologize to not answering @Kingofthekush420 questions. This is not because I ignored - but rather because I have bought an SOP from someone on this forum, and I am not sure how much would it be okay to disclose given how much effort he has put into the method.

- the question I posted is about starting material and not about the reaction itself, specifically not to be having getting into the details of the method that doesn’t belong to me.

I have tried many different solvents and many different reagents (pretty much every single one described in patents and papers apart from those which I think I am not ready for yet, such as TIBAL from the original d9 or KotBu/KOtAm/Nah bases to try the d8-HCl-d9 route). Also haven’t tried any hydrogenation reactions.

So yes, “this guy” has been doing the AlCl3 reactions, as well as many-many others. Its not the result, its the process that matters to me. + I have access to analytics, so I don’t need to be poisoning/biotesting.

I test at least 4 times a run - but for some methods I tested every 10 minutes to see the dynamics of the reactions. If there were variables I found interesting (like solvent ratio/catalyst eq - I was running multiple reactions simultaneously. My max was conducting 5 reactions at once testing every 15 mins, thats 20 tests an hour

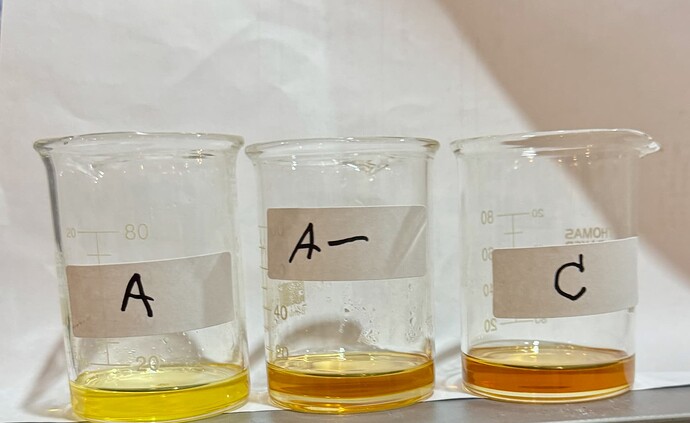

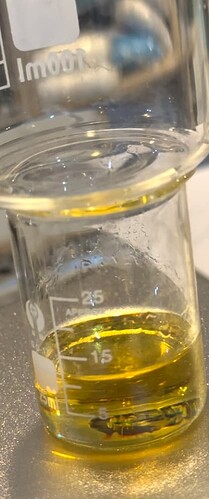

But well, I must really be expressing my thoughts in the wrong place. @Dr_Jebril thank you, the colour indeed fades but still not quite to the “A” category