Hey guys! We have a 24 trays commercial oven. Each tray fits about 2lbs of hemp. What would be the optimal time for Decarboxylation at 100 degrees cel?

At that temp, I’d estimate 30-35 minutes depending on container. But yeah search. Many here more knowledgeable than my off the cuff comment

Define “commercial”.

As in designed specifically for decarbing cannabis?

Or “used restaurant equipment”?

If the later, is it a convection oven?

There are arguments for and against decarbing before extraction. You might want to investigate those.

heating in the presence of oxygen isn’t necessarily good for our target compounds.

some folks are making better use of their CO2 extraction equipment to pull the terps before going after the cannabinoids (see CXE)

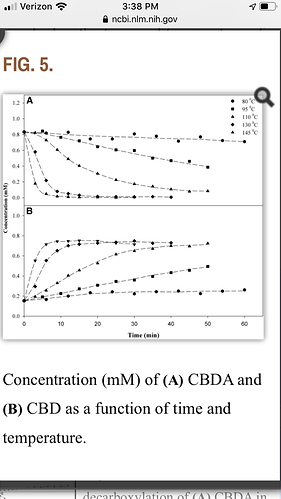

As in the first hit on that search includes a graph on the subject…

Temp consistency and time to reach temp matter. If you’re not using an oven with circulation, you may find that decarb is uneven across those 24 trays. If you’re not drying consistently, you’ll see variation from loading to loading. Grind matters too.

It’s fine to ask a stranger (3rd party analytics) how your decarb is going while you’re starting out, but getting your analytics in house sooner rather than later is highly recommend.

Absolutely, hence off the cuff comment. Way to many variables to answer well without more information. ![]()

shop vac as source of vacuum? Novel concept.

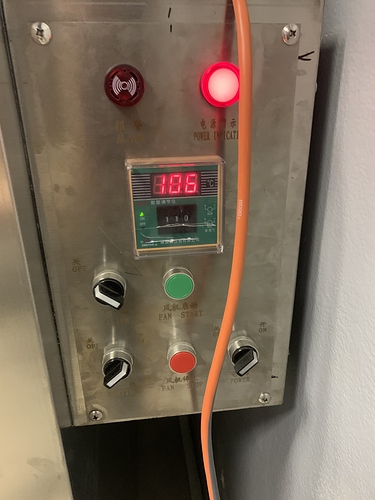

Thank you! We are using oven with recirculation. Did couple runs today. After hour and a half with 100 degrees c, the room start smelling real bad, even with the filters and I can definitely see some fog. Got couple samples 45 min and hour and a half. Will get the results on Tuesday. Probably an hour would be the most optimal time. By the time hemp is decarbed our grinder can process 50lbs of ready material and it is ready to be extracted.

We’ve found it is a great way to clean the grinder blades without taking it out