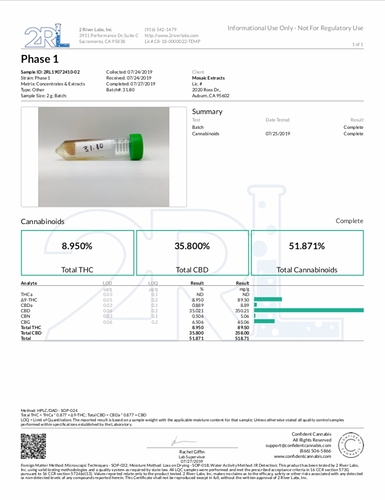

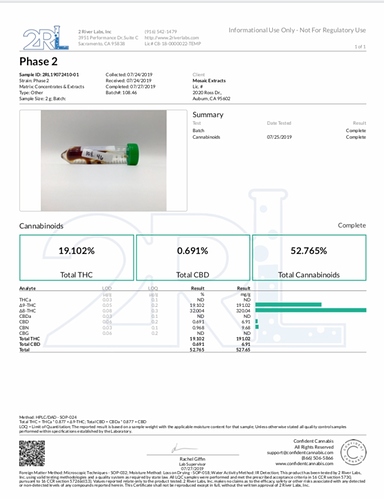

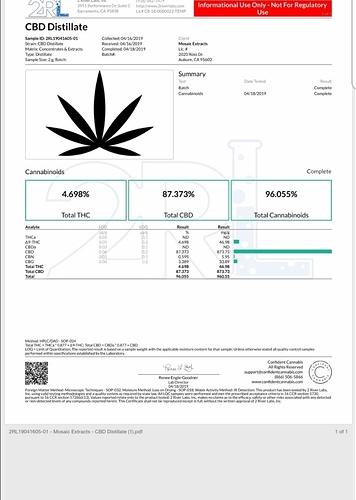

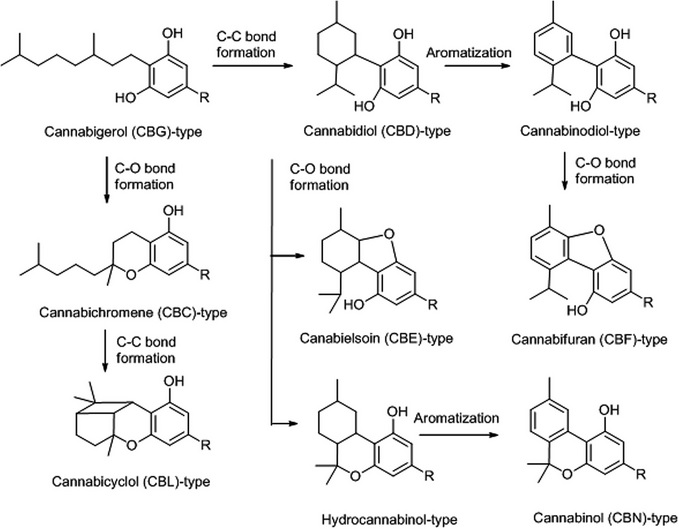

While attempting to convert CBD and Delta 9 in hemp mother’s liquor to CBN I instead achieved a high efficiency conversion and isomerization to Delta 8 and Delta 9. I have attached the COAs from before and after and SOPs for everyone’s use. The parameters can be tweaked slightly to achieve complete conversion to Delta 9, isomerization to Delta 8 or degradation to CBN. Happy R&D gang!

Here is the summary of the conversion test we performed including equipment, procedures, and yields.

Materials used:

-

SH-2 Stir Plate -

20mm flat magnetic stir bar -

Mercury Thermometer -

Infrared Heat Thermometer -

Stainless Steel Lab Spatula -

Gram Scale -

100ml Pyrex Beaker -

250ml Flat Bottom 24/40 Round Flask -

250ml 2-neck 24/40 Round Bottom Flask -

Claisen adapter 24/40

-

3-way Distillation adapter,75° 24/40

-

2 x 24/40 Ground Glass Stoppers -

13.300MM Liebig condenser

-

Vacuum take-off adapter 24/40

-

2 x Laboratory Stands

-

WVP-02 Water Aspirator Vacuum Pump

-

Circulating coolant bath -20C

-

Insulated Coolant hose

-

Vacuum hose

-

2 Liter Vacuum Filtration Apparatus

-

Qualitative filters

-

C-Bleach

Procedures:

-

110 ml of oil/pentane solution is taken from the mother liquor. -

Oil/pentane solution is added to the vacuum distillation apparatus and solvent is recovered yielding 51.52g of purged oil. -

14.61 grams of purged oil is added to a flat bottom 250ml round bottom flask and heated to 100C with magnetic stirring applied. -

4.61 grams of C-Bleach is added to the stirring hot oil. -

The material is brought up to 140C for 40min and 150C for 5 min with vigorous stirring to ensure aeration of the material. -

The hot plate is then turned off and the material is stirred until cool. -

The oil/c-bleach mixture is recovered with 99% isopropyl alcohol and filtered twice though double layered qualitative filters to remove spent catalyst. -

The isopropyl alcohol is then vacuum distilled out of the reacted oil mixture to produce a final yield of 10.0 grams (68% yield by wt.).