Send dims

I’m looking at getting new blades made locally for our used Lab 1st wiper.

ran into these guys (india) Carbotech Engineers asked for a quote.

assuming glass filled PTFE is the most appropriate. would certainly consider carbon filled PTFE if I could find it.

looking at mcmaster and grainger for springs.

https://www.grainger.com/product/SPEC-Compression-spring-Stainless-781AU4

McMaster-Carr

i managed to adapt some VTA blades into a Pope WFE, they’re carbon-impregnated PTFE and in our experience so far, literally never wear down. don’t expect to ever have to change them out, saved buku bucks compared to replacing the OEM PTFE blades from Pope. can’t speak to glass-filled but i’m over the moon for carbon-filled.

ratio would have some importance though and though i’ve asked, Root Sciences did not share the ratio of carbon to PTFE so couldn’t help you there.

are you having trouble finding carbon-filled PTFE stock? no doubt youve already googled but back when i was investigating getting our own carbon blades fabbed i found more than a few companies like this looks like they could help you out, including with blending to a ratio to fit processes

Thank you!

VTA wants about $100 for each 55mm segment. I’d would need 27, and I’d need to machine them.

Waiting on quotes for carbon filled ptfe to throw in the CNC.

cheat code: the ‘SKR Wiper Block (VKS 95, VK 100)’ [SKU: 1133] are around 105mm, and cost $75 each. still expensive but was the key to cutting that cost for me.

CNCing will be cheaper still, if i had one i’d have gone that direction but did not have time or $$ to buy and learn CNC, as much as I wished I could

12"x12" x 1/2" sheet of carbon filled PTFE for ~$300.

looks like I could get 3 sets built locally for about $2k if I use carbon filled PTFE. won’t cost but $200 less to build a single set (based on drawing + programming time).

not sure I’m going that route yet, but I don’t see as we are going to need 3 sets of “forever” blades…

if you only need one set, you could keep the rest of your sheet for making blades to sell to others? or just sell the other two you got made?

‘tired of replacing your WFE blades for $800 a set every time a high-residue batch comes along? I’ll sell you a set for $800 that will last forever!’

certainly I wish someone had offered that to me like 2 years ago

Yeah, if we bite on that bid, I’ll definitely post here to make the other sets available…

Carbotech Engineers wants $900 to land a set of (modified) lab 1st style blades in carbon filled PTFE.

Vs $350 for a set of PTFE from OEM out of China.

Currently “Mod” is simply cutting into 5 sections. Considering installing springs as well.

Anyone run into problems after sectioning their wiper blades?

Edit: After watching this, I’m ditching the springs and sold on sectioning.

Pope Scientific Wiped-Film Drive Removal Instructions - YouTube

By all means tell me I’m wrong if you’ve gone down that road and regretted it (@Kingofthekush420?)

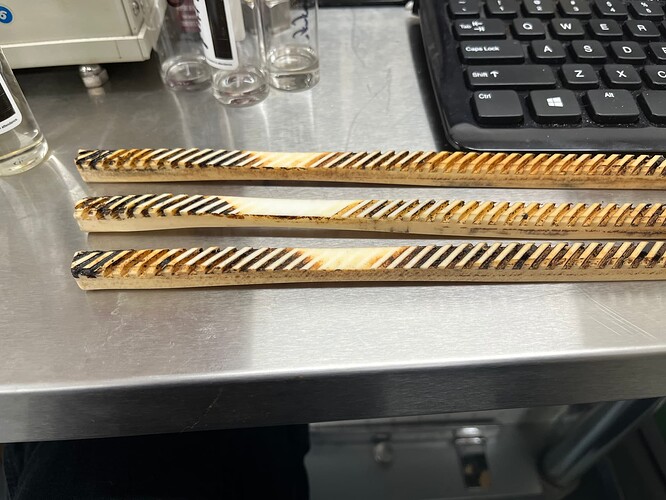

Almost all of my scrapers less one Chinese wiper were segmented. The bottom ones tend to wear quicker like this though.

Thank you! I’ve only pulled used Chinese wipers apart…some had segmented blades, some did not.

…so instead of the 15 segments I need, we order 21.

at least in this rig, the non-segmented ones ALSO wore out at/near the bottom.

Those look simple enough for a not-braindead machineshop to replicate in any material you could want, presuming the appropriate material is procurable.

Having not worked on many wipers in my past, I presume springs refers to springs on the back of the blades to keep semi-constant tension along the length of the blade?

Seems like a good idea to me, even if you’re doing a multi-segment blade…

Outward force is usually enough at those rpms to not need springs. I think the springs are for more viscous things like foods and plastics.

Rollers don’t have springs either, same principle

Yes.

My primary concern is that I have a vague recollection of trying to source said springs, and discovering that those available from Grainger or McMaster were too powerful.

…and, I have you in the room at the time.

(Hallucinating again?!? Maybe you arrived after we got it back together?)

That does tickle a memory or two in the back of my head as well.

Carbon blades might be useful for a project I’m working on right now. If you can give me dimensions of those I can bang out a model and kick them around my usual suspects to see if I can’t get them done up at a reasonable rate.

re: springs, i’ve only worked on two styles of WFE, one (VTA) uses slightly flexible SS brackets, which work well but sometimes have to be retensioned.

the other (Pope) does not use springs and trust centripetal force to keep the blades against the still surface.

I havent used any types with springs but I wonder if 1) they’re necessary given the RPMs we’re dealing with, and 2) if they lead to increased wear via that additional force. especially in the event of residue buildup, where it’s holding the blade face forcefully against what’s essentially a belt sander. maybe if they’re loose, they have a chance to ‘skip’ over irregular surfaces more? that’s purely speculation.

also, I’ve not worked with non-segmented blades but I’ve always been a fan of segmented. it can ‘fit’ to the still body and any irregularities in the plane of the still surface, and often times only one or a few sections will wear down due to hot spots/irregularity/whatever. the ability to replace only what sections are needed saves on blade purchases

well, it did before we got our invincible carbon blades in there ![]()

That is a very interesting wear pattern for sure! How long/many kg worth of run time does it take for the PTFE blades to clap out like this? I would think that you are on the right track with the carbon impregnated PTFE blades. Super interested to see what you guys come up with!

That’s how they came in the door…

Oh! Clearly I didn’t read close enough that this was a second hand unit, my bad!

There is a machine shop local to me that handles the basket and wiper blade fab for a local glassblower that blows wfes for Eastman. If you run into a brick wall, I could reach out to them and see if they work with the fancy PTFE

I can understand that sort of damage on a stainless wiper, but wtf runs a seethru wiper to that point?!?