if I do it, maybe 80.

@anon13684764 looks great, I was looking at doing the same thing for a quick start in OK a few months ago, glad to see someone made it happen.

We went with a HAL booth.

Damn booth nearly killed me the first time we released any significant amount of butane when I had to do some troubleshooting. The booth was larger than their normal size, and the breakers in the panel didn’t have a high enough amperage to handle the fans ramping up. So then here I am opening up my unit, releasing a controlled amount of butane to do my troubleshooting process, and then all of a sudden I lose my lights and my ventilation when the breaker trips. I had to scramble to get out of the room with it full of butane, and the lights / ventilation off. I ran out of the room, opening and closing the door as fast as possible on the way out, and went over to the panel. Eventually I figured out how to reset the panel and clear the air out of the booth.

That’s embarrassing and how did they respond to this when you told them?

Quite frankly they weren’t very helpful. You’d think after giving us a booth with a hastily up-sized design - where not everything was scaled up properly, such as the breakers being matched to the increased amp load of the larger fans - they would do more to remedy the situation.

We tested the unit upon startup, but since it has multiple levels the fans can ramp up to, we only tested to see that it was responding and got it to ramp up to the first level. We didn’t think it was necessary nor did we think it was necessarily wise to release enough butane to trip it all the way to the highest level during the test.

Just goes to show that shit can sometimes get past multiple engineers, city planners, and a fire marshal, and still end up not working right and potentially ruining your day.

@GandalfTheGreen after you got it up and going, do you like it? What was the setup like?

Did you have an ignition source in the room?

If the breaker panel is inside the room that would be his ignition source.

There were no ignition sources in the room, no. It was a fully compliant C1D1 enclosure and we didn’t bend any rules by bringing anything else in there that we weren’t supposed to.

I was more concerned about inhaling too much butane / running out of oxygen / getting the thing reset so I could finish doing my job than anything else. Because I had open up a section that had some liquid inside, enough was released to put the enclosure around 35% butane, according to my meter. Really not something you want to be standing around breathing for any extended period.

Response to BG305, the breaker panel is located outside the C1D1. Which was handy, because I was able to reset the C1D1 from outside the hazardous area.

Once we replaced the breaker with a larger one, booth worked fine. But the fact that we had to go through that whole ordeal to make it truly safe to operate kinda burned me, not gonna lie.

Got any pics or links? Weve already studied the fire codes and electrical requirements for everything. Were putting it all together this coming month but anything on the ventilation and so forth would be a nice touch aswell. Do you have a changing room in the place?

A hazardous exhaust systm is required within the Ethanol extraction room in accordance with IFC

5003.8.5, 5004.3 (Best Practice), 5005.2 (Best Practice) and IMC 505.0.

All metal objcts including ductwork, hand sinks, water piping, etc. shall be grounded / bonded in

accordance with NFPA 70. The extraction equipment is required to be grounded/bonded.

The exhaust fan shall be listed for hazardous exhaust duty and must comply with IMC 503.2.

Hazardous exhaust registers/vents must located within 12 inches the floor within the extraction

room or hood.

The expelled exhaust air outlet be separated from operable doors, windows, flammable liquid

or gas storage, and ventilation air inlets by a minimum of 10 feet.

The location of the exhaust and inlet air openings be located to provide air movement across all

portions of the room. There must be airflow across any area where there is a potential for the

presence of Ethanol.

Ty very much!

any one have experience installing the c1d1 kit? can any electrician easily do this? definitely thinking about going the paint booth route.

https://www.larsonelectronics.com/product/153626/c1d1-explosion-proof-extraction-room-equipment-package-designed-for-20-container-extraction-rooms

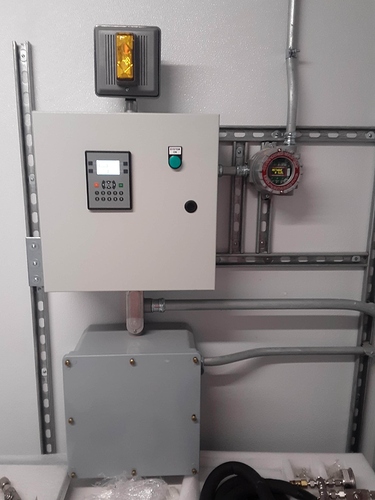

Used Larson Electronics for most. Great prices. have been on projets built 2 working on 2 now

shipping containers are $4k or less delivered. electronics, sensors, lighting, plugs and all conduit less than $15k. frame out and insulation so can complete units for way cheaper

This is the way

Want. Good work @Poizzin

did this pass how did it go?

did the larson kit pass inspection?

dont take rowans advice

My company builds C1D1/C1D2 containers, along with full blown FDA/GMP production clean spaces for the pharma industry. I personally used 3 of our 40 foot C1D2 containers for a year and a half as a customer before joining on to head up the cannabis applications here.

A kit might be enough to get you past an inspection, but there is a heck of a lot more that goes into designing a safe classified area than just special lights, plugs and an exhaust fan.

I’d be glad to answer any questions regarding classified spaces.