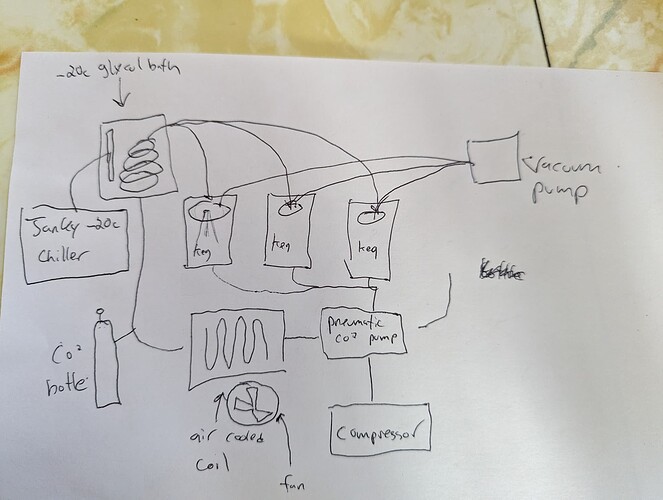

Hey gang, brain was going a thousand miles a minute last night. Had an idea for building my own freeze dryer setup, wondering if this makes a decent amount of sense.

I’ve got a pneumatic pump and compressor already, and some kegs, and I think I can slap this together for under a grand hopefully.

The system would function in stages. With the expanding liquid/gas CO2 as the coolant rather than using cooled trays.

The kegs would contain my flowers (actual bouquets because I’m a no fun dork now, and real flowers actually make money ironically enough) there would be a port cut into the top to put things in hang drying, or maybe a little shelf system.

It has the added perk of being able to run what is essentially a modular system, with dozens of separate chambers that can be added.

The insulated keg is the expansion chamber, cooling down with the expansion of the liquid CO2 into gas, to a maximum of 50psi. I’ve got an auto switch that will kick on the pump at that pressure, which then condenses the gas back up to 400-600psi. I’ve got an equilibar valve that will be set to the appropriate psi on the pressurization side right before the kegs, that won’t allow the liquid through to the expansion chamber until the right psi is achieved. I’d use a needle valve for each keg to control the expansion into the chamber’s.

The liquid gets cooled off the pump via an air chilled coil, then into another cooling stage (janky AC chiller coil bath), then the -20ish liquid CO2 is allowed to expand into the kegs, hopefully hitting -70c over time).

The CO2 system also connects/powers a -70c cold trap, with a coolant reservoir, to catch and freeze and water before the vacuum pump.

Once the correct internal temperature is achieved, I isolate the keg.

Once the keg is isolated from the CO2 side, it is opened to the vacuum side, and we’re off to the races.

Does this all make sense?

Attached is my napkin drawing.