Hey Future,

What do you make of this. We extract for thcA target molecule, by way of sugar/diamonds. Asking for your hypothesis.sss, theories, opinions and any thoughts on some questions at the end. Thanks in advance

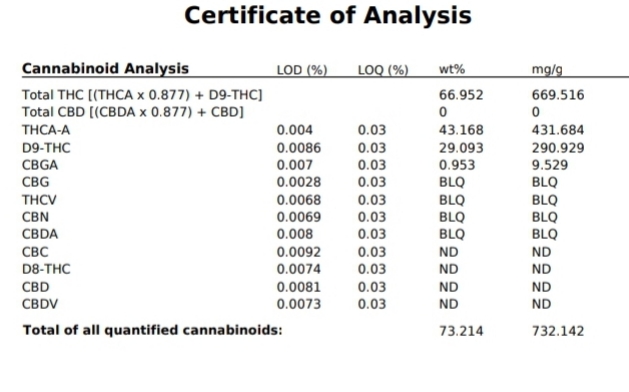

177kg of dried biomass. Tested Nov 11 2021, thcA=23.2% w/w, THC 1.60% w/w

April 22 2022, We hydrocarbon extracted at 0-5c, CRC’d and left to sugar out.

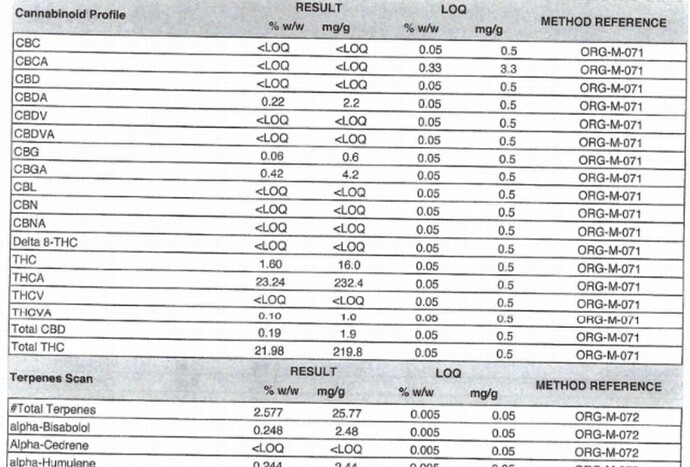

only this run did not precipitate like almost all our other runs, we had some sugar and diamonds forming at the bottom of the crystallization vessel but no where near what it should have. We let the pot sit for quite awhile to push the precip, but to no avail. Sampled and tested the crude on June 1st 2022 and results are 43.1% w/w thcA and 29.0% w/w D9-THC, cbgA 0.95% w/w.

When we run & recover the crude/solvent solution temp never gets above 15c (59F), jacket heat temp 46c (115F) max. We also recover under vacuum at certain points to ensure the solution stays cold.

The only time the post run extract sees elevated temps is post crc while in the crystallization pot where we ramp up temp to 35c (95f) to 38c(100f) to 40.5c (105f) for standard precipitation/crystallization parameter. Even seeded this batch with 20g of 85% w/w thcA sugar to get it to kick.

Can can thcA decarb if sitting at 95-105f for 30 days?

Can CRC’ing cause a decarb? or adsorb/absorb thcA thereby enriching the D9thc quantitatively? CRC’ing with standard, Silica, Alumina, B80, T5 or T41, DE

Has anyone else had a similar experience?

The biomass COA on this was done on the flower, we run the popcorn, shake/trim and smalls of the flower so I’m aware there may be slight discrepancy between the biomass we run and the tested flower, that said, this is what we always run. and have done lots this way.

We just did a 19kg yield that tested 88% thcA and fully crashed in 5 days at room temp. This flower biomass COA’d 25% and the lot looked like horse shit, came in multiple bags some with fan leaves, some had stalks, milled shake/pop/trim. But ran the whole lot and it was one of the best runners we’ve had. Same run parameters as the non-crash case I’m posting about here.

We source all our biomass from legit, vendor qualified, licensed and regulated producers. Up here in Canada, it is extremely difficult (but not impossible) to get away with shady practices under the legit Health Canada side. EVERY process is under camera, chain-of-custody, access control and very expensive to get licensed and build out an approved facility. I find it hard to believe any vendor would risk their license and whole business to try and sneak one past the goalie.

My logic, rationale and hypothesis is pointing to

1.) the biomass decarb’ed somehow within the 5 months of when it was tested Nov 2021 and when we ran it April 2022. Thereby increasing the THC to thcA ratio thus inhibiting crystallization (I am well aware THC/thcA ratios effect crystallization)

If this is the case, is there any known way to separate THC and thcA with a ratio as listed on the coa, 59.7% thcA to 40% THC w/w ?

2.) we calculate our crc media quantity to be used on the theoretical preCRC crude amount. We have been using 13% w/w as a standard based on all previous successful runs and has been working. This case actually yielded approximately 23% as calculated by the total biomass run minus the waste biomass after the run. (yes I know some moisture could be lost from the biomass as it is being degass’ed)

This being the case, I’m still not sure how a lower CRC media amount could cause a higher THC to thcA ratio, or am I overlooking something

3.) did something other than THC in the post crc extract prevent crystallization due to not enough CRC media being used? AND did de-carbb’ing happened in the 37 days from when 95F heat was first applied to the extract to when the sample was taken for testing? Can CRC extract decarb at 95F in 37 days?

Again, thanks in advance for your thoughts and opinions.

here are the COAs

BIOMASS

EXTRACT