The high one was high af imo 3.74 ppm the others were right above 1 ppm which is the allowable tolerance here in Montana I’d love to have zero lol

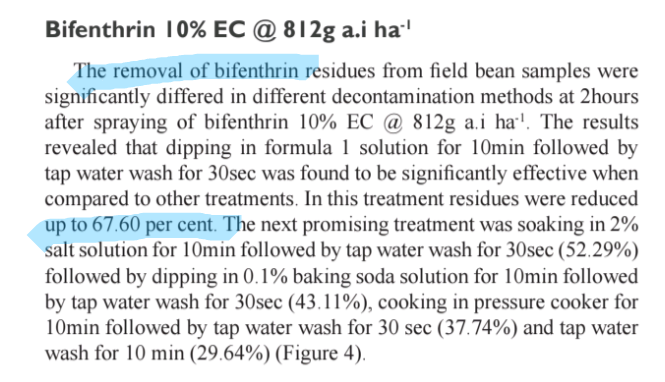

LLE with this vinegar + baking soda + lemon juice solution? Looks promising in beans at least, 67% removed in one wash. With love from India “Decontamination methods utilising house hold practices for removing pesticides on field bean for food safety” 2018

Is that describing washing it off of the surface of vegetables? Specifically beans? I can see that maybe working but for distillate probably not. I’ll pull up the coas later, technically they already exist here on another pesticide remediation thread if someone wants to dig that up and save me the time.

You can do a LLE with ACN (acetonitrile) and Heptane as they aren’t miscible. The ACN will grab the Bifen.

Mix oil with ACN,

add equal part of heptane enough to capture all of cannabinoids

dilute with RO water heptane is not miscible with water this dissociates the cannabinoids from the ACN.

Do final water wash multiple times to ensure acn is fully removed. Then pass over dessicant to remove moisture & discard and properly dispose of ACN/water layer SAFLEY.

Keep heptane/oil layer. Recover heptane, test oil

Yes that is for beans but demonstrates a good aqueous solution for bifenthrin VS just water. Seems it could be good for washing tainted cannabinoids dissolved in heptane. A series of washes with that solution followed by a few water washes would work I think.

I think we should still consider the implications of trying to remediate or extract this material in the first place.

Contaminating perfectly good water that IMO is worth more than the cbd is a shame

This is the only petition I’ve found in a short search but there should be some action from all of us to at least try to get this banned

That’s old but maybe still worth signing?? I have no clue

Also came across this

“ Bifenthrin is known to be highly toxic to bees. It is a restricted-use insecticide of the pyrethroid class that is linked to autism, Alzheimer’s and Parkinson’s diseases. It is a highly persistent pesticide that is considered a Per- and Polyfluoroalkyl Substance, or PFAS.”

As some others have said, water wash is a powerful method of removing most pesticides that are water soluble, and is really only used with distillate on a regular basis…but that doesn’t do much good for BHO products which are meant to be sold after extraction and solvent purge.

The usual go to for pesticides is MagSilPR filtration through a CRC column, but if you look at Bifenthrin as a molecule it has a lot of flouride ions. This would suggest that an absorbent used for flouride removal would be suggested such as alumina. CRC as a color correction is only one of its many uses and I would suggest experimenting with using it for pesticide correction. BHO makes some of the best hash and the extraction method isn’t to blame for the fact that the biomass was sprayed with something that has to be removed.

If you follow a light absorbent usage method like @Dred_pirate teaches, you will be able to find the right amount of absorbent to correct your oil without over stripping your material.

I don’t have my notes/data with me but I’m pretty sure MgSil did not work in my clients case

There was also another pesticide present that also was very problematic- I’ll have to look back and see which it was - but I remember them both coming thru on the crc as well

In that case I would lean heavily in assisting MagSilPR with something like Alumicel since that alumina comes in various pH values. MagSilPR is alkaline so an acidic alumina will provide an absorption quality along with a pH swing…and pesticides fucking hate pH swings.

If you dig around hard enough you can actually find the pH at which a pesticide degrades. Agricultural wastewater folks have to deal with this all the time and it’s one reason why brine washes are so popular.

The extract went thru “THC remediation” as well and the pesticide also made it thru that process too

If you aren’t applying a process designed for the contamination you need to get rid of them all the other processes that happen to work are a bonus. Bifenthrin has been dealt with by others, PBO is way more of a technical challenge.

Also, “THC remediation” can mean a lot of shit, with most of it doing nothing for pesticides that make it through basic cleanup.

At what cost?? Between yield loss, conversions/byproducts, waste disposal, reagent costs, and time is it worth it?

Not trying to be sassy I’m legit asking who’s got that data

THC remediation was all sorts of things yes, but Ph swings were involved in this case I believe

Yield loss and conversion products from 50-100gr of absorbent?? Sass is always enjoyed but not working through the tools available is rough.

What makes a pesticide easy or hard to deal with depends on how well you target it, what it’s affected by, and what part of the process you attack it at. For example, if your oil has a lot of lipids left then the correction method isn’t going to be very efficient because large molecules are dealt with first. Bifenthrin has a negative charge which makes it a great candidate for absorbent strip, but you’d need to approach it at the end of the purification process so the tools you use are as effective as can be.

I only chimed in because the technical aspect suggests the available tools, like pH swing and surface chemistry, should solve your problem if applied correctly. Yield loss is more related to using the appropriate amount of solvent in relation to the amount of absorption, side chain reaction is more related to creating too much pH change or too much heat…which can be caused by using too much absorbent on too many contaminants.

De-gumming (LLE) Brine/heptane was done and does reduce but does not eliminate. Same with magsil and crc. Those are just facts that I’ve come across

I believe there’s a hexane extraction lab that handles bifethrin contaminated hemp but again I’d have to look at my notes from 2017

I would suggest you try alumina based methods. Bifenthrin has three flouride ends.

So I looked back at my notes that I have on my email, and I think the best reduction was with filtration media (bentonite/clay, and activated carbon) but it needed multiple passes and only reduced by 85% … honestly I’m not sure that alumina media was used but I think maybe. This is why lab books are so important

Chlorpyrifos is the other pesticide that is problematic

And I agree going after the active groups and degrading the pesticide, or using them to attach to media, is an efficient route in theory but it’s also pretty harsh on the cannabinoids

That one has enough chloride ends that I would be shocked if magsil didn’t remove it, and the only barrier to removing it with magsil that I could imagine would be not using enough magsil or using the magsil too early in the purification process.

Alumina is used for flouride clean up all the time, magsil PR loves chlorinated pesticides, and chlorinated pesticides often degrade well in water washes but you have to be strict about what pH the solution is experiencing and for how long.

I have test results saying it didn’t. It went out to third party lab for this process so I cannot speak to their techniques as confidently as if I did it but it had zero change

Well as surprising as that is, the way most things go in this stupid fucking industry it’s hard to figure out why that oil failed to remediate without getting involved in production. Generally speaking your oil must go through absorbent processes with a non-polar solvent, which I’m assuming you did. Since you mention THC remediation I’m assuming this is a CBD production…so you could always crystallize and then process the mother liquor separately