No clue who actually made this thing, picked it up used and there’s no data plate or serial number to contact an OEM about

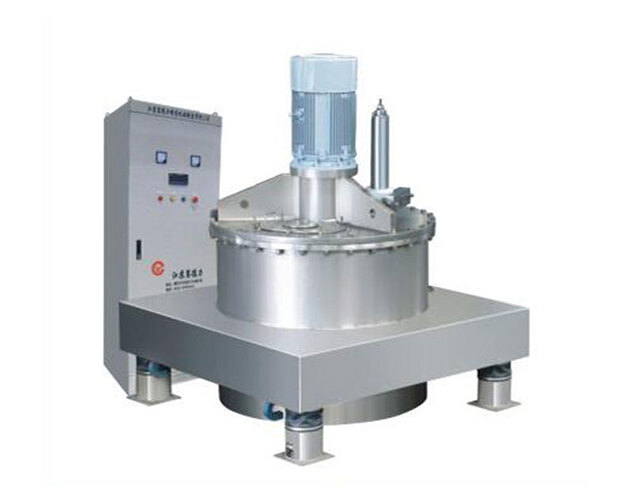

Pic isn’t of my exact machine but it’s this same style floodable, direct drive with the motor up top

No clue what grade or brand they originally packed the spindle bearings with but its dark blue and doesn’t like the cold very much. Running around -45 to -50C in the cooling jacket and overnight it gets pretty difficult to turn by hand, after running at low speed for ~10 minutes you can see amp load drop significantly on the VFD as it warms up. If you load 80 lbs of extraction bags into it with the spindle bearings cold it won’t start up at all and the VFD will throw its hands up and give an overload error.

Obviously this isn’t ideal, I’d much rather be able to load extraction bags and startup right away in the morning instead of letting it run at low speed for 10-15 minutes so the VFD doesn’t pitch a fit.

There’s other issues with the greasing systems on these that will need upgrades too btw, if you remove the coupler access plate - which didn’t have a grease zerk on it but a spring loaded oiler cap and a clear plastic hose connecting the access plate and centrifuge with two cheap push to connect fittings - I intend to replace that with a braided line and the proper grease fitting.

Curious if anyone with a similar unit has replaced the grease with something better suited to colder temps and doesn’t turn rock hard overnight, and if so what you used, or suggestions for me to try

3 Likes

So, no idea what the actual grease they used is but searching for “blue bearing grease” turned up a couple possibilities here on US shores, none of which is a good fit for what we’re doing with these jacketed centrifuges:

Mobile Blue Polyurea Electric Motor Bearing Grease, NGLI #2 description says its specifically formulated for vertical motor bearings, min operating temp -4F/-20C

LPS ThermaPlex Blue Lithium Complex Multipurpose Bearing Grease, NGLI #2, min operating temp -22F/-30C

Exol Blue Lithium Complex Grease, NGLI #2, min operating temp -20F/-28C

Kent Blue Grease HT, NGLI #2, min operating temp -15F/-26C

Obviously none of these are where I want my extraction temps or thermal fluid loop to be

Ordered up some Ravenol Arctic Green lithium grease, supposed to be good to -76F, I’ll keep you posted

3 Likes

I’ll say this with a lot of forewarnings I have no clue

If this fuge has proper seals or not but maybe it’s telling you to switch to heptane or hexane and run it room temp. You’ll need to ensure it’s safe and at minimum have proper grounding and run nitrogen in it the whole time it’s running.

1 Like

Klubersynth LF is ok to -60c

2 Likes

I’d say more likely that its saying the people who put it together didn’t think or care about what it was being purchased to do, or under what parameters it would be performing. This is hardly my first experience with Chinese square peg-round hole “engineering”

4 Likes

Almost every piece of machinery I’ve gotten from China has needed serious TLC to get working properly. They neglect properly lubing their stuff in my experience for sure.

5 Likes

I have a mile long list of Chinese repairs on new equipment that leaked, was cracked, or just not welded at all.

My favorite was the entire scotch brite pad that was lodged in a “stainless” condensing coil.

5 Likes

Is it belt driven?

Maybe buy a new belt, make sure it’s tight, and make sure solvent doesn’t get on it. And keep it clean!

Belt resistance is a major amperage problem with motors.

Not belt driven, motor sits above the basket and drives it directly via a lovejoy coupler

2 Likes

So far, so good.

Replaced the grease zerk tube thing with a proper angled zerk from a local industrial supplier, then pumped 2 whole tubes into the centrifuge spindle over about a weeks time and let it puke the blue stuff out the bottom seal.

No longer need to do a warmup cycle before loading bags in

Took more grease than I was expecting to get this spindle to stay free-turning at low temps so I’ll be ordering more shortly

If anyone knows of another centrifuge in this style in or relatively near Colorado I’m looking for a second one.

2 Likes

There’s a couple different ones for sale in the classifieds. I would go with the ACE40, but that’s because I’m partial to excellent equipment made and designed by expert operators and designers. They’re was 1 in the classifieds, but I’m not sure if it got scooped up or not.

I was also thinking since you picked your fuge up used that maybe it was used to spin vegetables or something, and hence why you wouldn’t need grease the can reach down to our proper temps. (But honestly, I have no fucking clue! That was just thought I had.)

1 Like

That things way too small for what I’m looking for…might not be easy to tell from the pic I posted but I can fit 120-150 lbs per load in this unit. I also prefer the motor up top design as its far less likely to have a leak due to seal failure, since the seals in it are limited to the bearing spindle and they aren’t steeping in ethanol and cannabinoid oils all day long.

1 Like

I totally get what you’re saying! I’m just wondering why it isn’t as prevelent as it should be. Makes total sense what you’re saying about the motor, and such. Yours is actually like maybe the second spinner I’ve seen with the motor on top, and the first wasn’t in our industry.

That’s a hell of a load you can throw in that bitch! Seriously! I think you put the most weight in yours that have ever heard… I think 60-75 is the most I’ve read about, but again that’s just from reading not actually seeing the things in the wild.

@Capttripppp we had to do some tweaking to figure out best extraction bag arrangement, but right now we’re able to fit 16x 5 gal mesh extraction bags in the basket for each run. Some variance because of different material densities but 120-140 seems to be the sweet spot for material that isn’t super seedy and heavy.

1 Like