Another 5L/10L kit going out today. I can’t recommend this enough for anyone with an extraction operation that is thinking about distillation. This kit sits on a 6ft table easily and operates on only 20 amps of power. This configuration easily distilled 1L per hour at low temps with a single e2m28 vacuum pump.

Another 10L kit going out today. If you have distillation needs for your lab we have kits purpose built for distilling your oils.

This kit is simplified for a new distiller and is made for extremely easy operation. Shown here is a video of a lab tech removing the flask and loading it back in. No grease. No shifts in the system resulting in vac leaks. No concerns about breaking expensive parts. DM for more details!

The Peyronie systems have been tested and are an absolute dream to operate.

Two stages of physical separation - one in the bend and one inside the top of the head - combine to create super clear distillates at low temperatures. DM to learn more about speeds and other configurations.

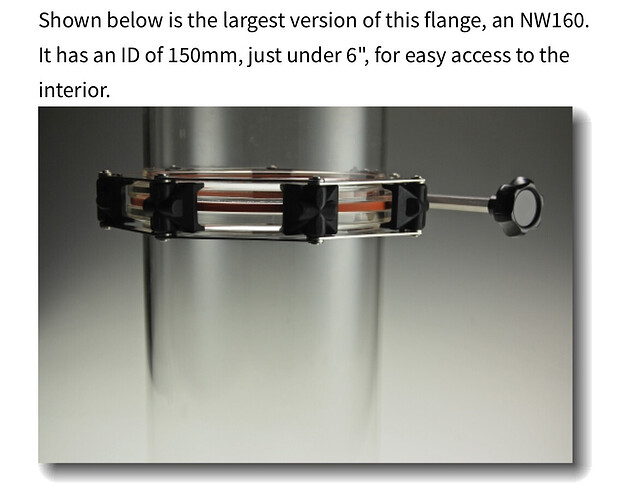

https://adamschittenden.com/technical/connections/nw-glass-flanges

They list max temp at 150C…which would presumably be problematic, but it may still be worth chatting with them…

That’s why you need a “Better Flange” ;). 150C isn’t enough.

Flange looks dandy…but the contact area on these clamps seems like more might be better…

Given that it’s the weakness point in the system, I would certainly continue exploring…because: Continuous Improvement & Manufacturing Productivity

Almost guarantee a more heat resistant version of those “knuckle clamps” could be had.

Process piping is sick AF,

Had the büchi sales rep stop by the other day to sell us a new reactor and they busted out this sales kit. Was super sick to play with lmao

Bigger clamps on large vacuum fittings generally are not the industry standard above 50mm. Almost everyone goes to this style and I tend to agree with that standard.

Given that the flange operates under vacuum, you really only need enough clamping to slightly compress the o-ring. These clamps are custom made for easy operation and to provide the necessary stability for reinforcing the vacuum connection.

This is the most dangerous clown shit ever. This is a fucking hazard and a complete liability. Alex is a conman, you can see it with this dangerously clamped apparatus. Stainless to glass is already banned in labs and this is a danger to anyone who uses it. This one takes the cake.

Pretty certain all the users who use stainless don’t put them on boiling flasks. Especially not metal clamps. Guess you missed some of the scenery before responding.

There’s a centering ring between the two, PTFE if you fancy

The summit one is straight up steel into glass

I don’t have a monkey in this circus but I do know that BR instruments may not see eye to eye with you.

Nope, they use them in the mild or cool sections. No boiling flasks, for boiling flasks you use ptfe. I have a ptfe chemglass one that I use if my glass one ever breaks.

As always, you couldn’t be more wrong about everything you’ve said.

I won’t dignify you with any further response.

I can just about guarantee that Alex did not run the system this way. I believe he uses those clamps to set it up, but once under vac, they are not necessary. I really wanted a high temp clamp for my boiling flask, but turns out it really isn’t necessary at all. I have had no leaks running it clampless.

For all the naysayers out there, stfu. This system really is the tits, and I couldn’t be happier with mine.

@AlexSiegel, brother the new units are looking sicker than ever. Keep killing it!

Where is the danger?

Differences in thermal expansion coefficients leading to an over tightened clamp exerting too much pressure upon expansion and cracking the glass; which if under vacuum, would lead to a catastrophic implosion and a bad day for the operator.

Personally I think dudes reaction is an over reaction for the temperature ranges you’d expect to distill cannabinoids at. it’s a still a risk forsure, but just don’t over tighten the clamps. It should be noted that any glassware under vacuum can implode, any glassware can break at anytime in process, theres always that risk no matter what your doing, but obviously don’t add to the risk with poor practices.

I like the simplicity of these systems quite a bit tho

So, not really outside of the inherent risk of running glass under vacuum ?