First test run the clay was dry when i cleaned it out. The next run it was full on wet clay. How should I interpret that? Did I add too much b80 first run? Both runs were almost too devoid of color. This stuff is black without crc

Curious if y’all have experimented with maybe a 1/4:1 ratio instead of 1/2:1

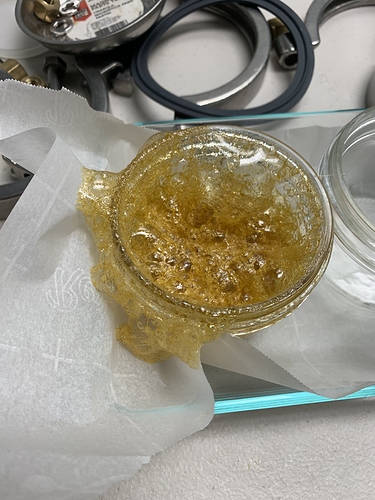

nice results! It looks like you got it working well.

I’ve done a 1/4:1 ratio, it seemed to come out about the same. I go for 1/2:1 just out of convenience due to my column size. When I ran smaller I needed more papers and stuff to hold it all in place.

This run was more like 1/3 : 1

This b80 is a nightmare to deal with tho lol. Does great but fucking with the dry clay is worse than burning man playa dust…

I need to figure some shit out. It’s gets everywhere when it’s all dusty like. Microwaving it Has a learning curve that’s for sure lol

yeah any of the adsorbent powders are such a fine micron, they will all be difficult to work with. It’s advised to wear a mask when working with them, you don’t want to get that stuff in your lungs.

I microwave mine in a flat pyrex dish, spread out evenly. From there I just slowly pour it into my column. The dust is kept to a minimum this way.

When I break it down, I dump everything right into a garbage bag and close it quickly to prevent dust escaping.

I didn’t go back to reread, but if no one mentioned… respirator or at least a good dust mask when you’re working with powders. If you can connect your crc to a vacuum pump while packing and rap the sides with a tool while you vacuum you will get a more manageable crc filling experience, and empty it while it’s inside a bag or other container to help control dust.

That’s the spot!

I called every welding supply in my town and they all only sell a minimum of 500 pounds but the one guy who offers nitrogen and solvent and all that good stuff said he usually has some overflow and he started to sell me that yesterday at $.50 a pound which is incredible so thanks so much for that advice it worked out

Excellent information thank you guys. I’ve definitely been using a dust mask and gloves. It says right on the bag that it’s pretty gnarly I take those warnings but you seriously

I think I’m gonna be using the stuff pretty often until I get some flame material at least so I picked up 100 pounds on eBay for pretty good price

Nice! I use a measuring cup to scoop my powder into column

The difference in yield is tremendous.

From 6.5% to 1.5%. Yes it’s shit material and I’m not running any more if it lol. But still that’s major

I’m about to run some super terpy shit that’s dark purple and see how it goes. I’m over running bs this week lol. I need to be more selective on what I’m running. It was a toll deal but I don’t see any incentive to pay me at if the end result is shit. I need to work on my contract too. This was just a hand shake deal

That much yield loss is inconsistent with what most of us have experienced.

The clay was like mud when I removed it from the column. Should I be increasing my ratio of solvent to material when using b80?

Any input as to why I might be experiencing these yield reductions?

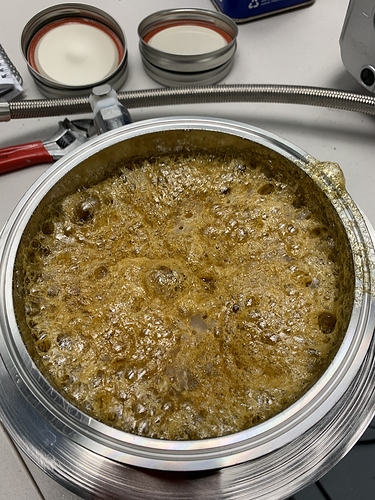

Not a b80 deal but since I have the attention of a couple of you guys… I’m getting fat muffins when I’m trying to pour and it’s bubbling and making a mess. How can o get a decent pour? Is there a trick I’m missing ?

Pouring from a splatter platter feels barbaric once you’ve used a spout lol I don’t know what’s up with the little jars or bowls or whatever you’ve got there but you can intentionally leave more solvent in your concentrate so it pours easier, which would definitely require a larger container to do additional purging in.

As for yields… what’s your solvent you material ratio? How many grams of media per lb of material? How much pressure did you use to push through? How did you verify you’d completely pushed everything into the collection?

Pour slower

Ratio is about 5:1 right now. Maybe a little better, I’m about to put an add on to my collection chamber to add six inches and hopefully increase to 8:1. My material column is 2.5 lbs and the collection chamber holds 12lbs of solvent as is. I usually do 1000g runs tho

For media I used like 300 grams to the 900.

I filled the material column with solvent with the pressure from the solvent tank. It’s at 60 warm. I run through a coil with slurry. Get to -35c. I fill material column, open valve to collection after flow stops above. When I open it flow returns. I ran till I hit 12 lbs of solvent. Then I nitrogen blast via the material column at 55psi. It pushed the remaining solvent out of material column into the collection column. When no more liquid came out i stopped pumping n2.