thats prob why you are channeling…pack the cake and put a filter ring on top of it with filter paper…if the ring fits too loose then put multiple papers to secure the ring tighter.

The only time I’ve seen a change in color is if I try to use the b80 on more than 1 run

If you’re dry packing you should use a vibrator

The verbage made me chuckle. ![]()

Care to elaborate about your method? Size of crc column? Size of material columns? How many columns of material do you put through before changing the CRC media? CRC to media ratio?

anytime u are doing more than 1 run yes you will see color change…you should read up on the thread

I’ve been using my vacuum to suck from the bottom of the crc column while we load media. Works really well. I don’t bake or pre-wet. I get consistent results.

Not b-80 but another pure-flo product.

Even if you have 10lbs of b80 in a 6x12 and only running 4x columns (24 lbs)?

Which powder?!!

How are you fitting that much b80 is a 6x12? I can only get 2000g into a 6x6…

just being blunt here…its just common sense. the filter cake that you are using doesnt last forever…you will see a color change if you use it for more than 1 run…the more runs you do the less effective the cake will be…unless im not understanding your question right.

how much you use is dependent on your material and the desired color you are targeting, whether its more than 1 run or not. its going to be trial and error. you cant just go off of someone else’s setup. i change my ratios all the time depending on what im running. the depth at which you set your cake can also hurt you in your runtimes.

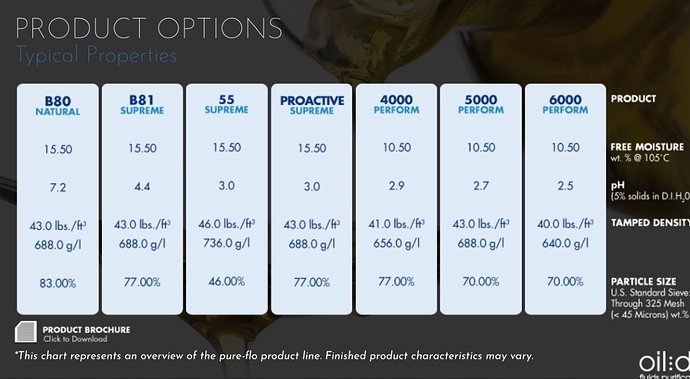

Here is Pure-flo’s product list.

It looks like Oil Dri uses the brand name Pure-flo to market their Attapulgite products to edible oil makers.

Pure-flo offers three product series, Natural, Supreme and Perform.

It looks like all three series come from their Ochlocknee, GA mine. Based on info on the Agsorb website (Agsorb is another subsidiary of Oil Dri) this mine is a source of Attapulgite bentonite clay.

As you can see in the chart, the ph decreases as you go across from natural to supreme to perform.

Pure-flo recommends the lower ph (higher activation) clays for more difficult to bleach oils. The perform series has the highest level of activation.

I have always gotten the best CRC results with T41. However, since the supply of it has run out for now and its characteristics have possibly changed permanently, I have renewed interest in trying other acid activated clays.

T41 is a bentonite clay at ph 3.0 with 10% carbon added.

I have some of the Pure-flo Supreme 55 and Perfrom 6000 here that I’m testing out this week. I also have some Summit powdered carbon that I will try blending in to see what happens.

I know @Krative has mentioned that he uses the Supreme 55 with good results. Has anyone used the Perform series before?

I also noticed this interesting quote from Shadownaught in the beginning of the main CRC thread:

I tried blending t5 with many different carbons and mixed ratios and it nvr worked as well as t41. I posted my results and ratios on the crc thread

Quality Stainless(@Killa12345) and CannaGas still have T41, and the next resupply of T41 is scheduled to arrive before the end of the month. B80 is now available through our retailers if they want to stock it and we can order other Pure Flo bleaching clays on bulk special orders if requested. Clay manufacturers operate at a scale that makes even single full pallet orders very unattractive to the manufacturer. Agrisorb makes products that are not intend for use on products meant for human consumption as their primary use is in delivering pesticides in farm soil.

That graphic is very useful for making decisions and OilDri is great at presenting data, it’s a little harder to gather data from other manufacturers as they present info on a product by product basis rather than a single source layout like that. I think its great that folks are finally taking bleaching clays seriously and doing their own research. In 2015/2016 it was very difficult to convince people to try clays in their process, but with an open source platform like this the level of processor knowledge is increasing rapidly.

i currently use perform 6000 i think its great

I use p6000.

Are you guys using a silica layer with the p6000?

Are you getting that nice white color when the oil is whipped?

Can you tell me what size column and CRC you use along with how long it takes to flush the column out?

I’m using 6x24’s with a 6x6 CRC filled up about 4-5" with media (T41 and silica) and it takes me around 5-6 minutes to clear a column and around 8-10 minutes to clear the column and filter using around 70PSI vapor assist.

No silica. 6x36 spool then a 6x6 crc. About 1500-2000g p6000. (Seems about the same as your estimate of 4-5” )

With cold solvent and enough powder it comes White.

I havnt timed the vapor assist but I’ve never seen any flow restrictions. 60-90psi N2

i use silica. havent timed also but i use 75-90 psi no glow restrictions as long as the crc is primed

Thanks for the tips. I’ll report back after a few days of RND