Nah, pretty sure the XD design or one of the others

uses lenticular filters.

They don’t, It’s their infinity filter. But you don’t need anything more than a plate and a mesh at the right size.

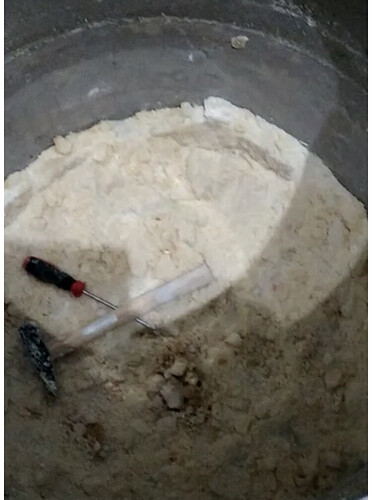

I just think that picture looks like a lot of work to recover yield out of the 3d filter. But if it works it works ![]()

I’m patenting a unique process for THCA isolate production.

The main advantages are it’s scalability (example: 30-35 kg input oil processed in a 50 L reactor) and very high yield (>90% of available THCA). High quality terps are separated as a byproduct, which is also a very nice thing. There is a separate small amount of byproduct mother liquor which contains minor cannabinoids and decarbed THC. The main yield from the process is brilliant white THCA, the crystals being a similar size to table salt or granulated sugar.

The process does require dry-ish oil for the input and can’t be done in-line while dissolved inhydrocarbon solvent. But it’s more efficient that the typical cold crash because you can process a shitload of batches at once and also get a higher overall THCA yield.

I’ve been winding my way through the patent process for several years now. Hoping to finally have the patent granted in the next few months. ![]()

Thank you for pictures

You guy s are way ahead on this one

And hopefully in time I can come up with something so sufisticated

Althou diamonds at scale would be my aim

RoguelabLeader

Vessel I am trying this on

Hope the rpm is sufficient to keep it all afloat and not stuck on the walls

Without an impeller as with a small impeller it was not much of a succes ![]()

Althou the ln2 works well with a 50 L Buchner to rinse clean

But yeah it s been a thoughroad

![]()

![]()

![]()

![]()

I don t see any grounding wires to your gear ! Argggg.

GROUND you GEAR !!!

lol we did shortly after the full install no worries. Plenty of wires going to a copper rod drove into foundation

Ahhh good job my friend

I can t say it enough ground your gear

I would be lying if I always do

But several flame throwers I made were deu to static it s a bitch and no fun

Welcome to fiture4200! Good luck with your patent!

I’ve been messing with small batch isolation using lots of different techniques, I was kinda a fan of a simple bucket tech crash I was using, but my homie wound up wanting to scale up so he hit up a decent shop for parts, and built something outta spares. Basically did the same thing as you but start way smaller.

Our design doesn’t use a “lenticular” or filter sock for a specific reason. You can’t wash your isolate properly with that design.

We have something new coming out Q2 that will allow faster filtration and allow isolate retrieval with no mallet tech ![]() We provide consulting on isolation if you want help building one or need the parts to build one! Obviously we also have certified turnkey units that have all the features you want in various sizes.

We provide consulting on isolation if you want help building one or need the parts to build one! Obviously we also have certified turnkey units that have all the features you want in various sizes.

Also, we will be releasing some new diamond mining tech and heat transfer tech that will be game changing! Stay tuned!

I was curious if you have pulled a full panel of the isolate finished in your isolator machines. Is there any lipids left over or carried over to the isolate side? Or how much d9?

Waiting on panels for isolated powder and decarbed material is also out for a panel. This machine was designed to be in line to an already established process. The likelyhood of lipids being present is highly unlikely. Id be willing to put money on the result being 99.9*

Also, I don’t think people realize how much separation is possible with silica and a couple crc columns. You can push over a thick ass silica cake for a water terps fraction, and then free the thc-a from the solid phase …

It depends on your SOP. We see 99%+ on isolate tested by our clients. No D9. Some terps left is usually what we see.

Long columns like that don’t work well because the length and weight of the rod. Your impeller can hit the sidewall when your volume gets high.

This is only true for the hanging impeller design. It flops around too much and will scratch metals into your isolate.

Our bottom mounted design has absolutely zero problems with height. Complete with FDA approved full ceramic bearings rated for the conditions. AKA “The GD1” from 2015 that apparently no one wanted but still ended up making one for both isolation and solvent recovery. ![]()

![]()

![]()

![]()

![]()

![]()

We have gone pretty far down the rabbit hole here… so many secrets that still have yet to be revealed. ![]()

< Breaking out the popcorn to watch the show! >

Shoulda’ just called it “The Baffler” or something lol (pls can haz?)

Please be very careful when working with butane outside of a closed loop system. You are asking to start a fire this way.

My thought process was that there’s no point of using a column that tall and narrow and unnecessarily engineering a bottom mounted design with more moving parts when you can just solve the issue by going much wider than the impeller, and shorter/thicker rods. We actually ran into this issue because gratefulglobz never tested the prototype 6x48 column model full of solution and we had to redesign the system to be more stable.

And isn’t your GD1 a wiper more so than a stirrer? I much prefer our simpler design that is easy to service and repair. IMO it works differently than what you guys have and has a lot more other functions like mixing oil back in, etc.

BTW, I like the direct refrigeration tech you use, but I think there’s better ways to implement the direct refrigeration you’re utilizing to make it more user friendly. Most labs can barely hold onto or find a highly experienced extractor, so a machine with a high learning curve like the Illuminated can affect a business’s ability to scale. From my perspective as a lab facility owner, I love the efficiency gains, but I also can’t have my entire lab be reliant on highly technical extractors. I rather have a slightly higher cost to operate with temperatures I can easily and consistently control, versus being at the mercy of my extractor technicians and halting my operations completely. This was also one of the main concerns I’ve heard from a few clients of ours running your system. When you have to send multiple trainers out to teach your client, training is going to be a new bottleneck in itself in terms of scaling.

Also, your clients mentioned the exact issues we figured they would have using a sock to catch their isolate. You cannot thoroughly flush the isolate with a sock by flushing from the top. Also, chilling with propane is not ideal for isolation.

I’ve been bringing out the popcorn to see if you have a fun update on IG lol

Know what’s better than a pre built machine from Extractor Depot or Illuminated? A custom solution, made specifically for your existing process, with in person consultation and sops for less money. Troll Face