So this is day 4. One day of temp cycling under said parameters in previous post. Then 3 days at room temp for the weekend. Seems to be having a positive impact.

I am starting the temp cycles again today. Ill be posting my progress.

What solvent are you using? I’d like to incorporate some more technique to my temp cycling. I want to pull the largest stones out, then heat the jar. After the heat cycle let cool and drop the seeds back in as the jar continues to cool. Sounds like a difficult task for butane. Might be able to accomplish with pentane. I may even try heptane

I am using a 70/30 n tane/propane mix. I dont really like it for diamonds though. All of my lids bulge at room temp. Going to switch to 100 n tane when its time to clean and refill my solvent tank.

I dont really know that it would be possible to go the route you want with N tane. Definitely possible with pentane. I think in Post Your THCA Pics/Vids either J12 or Diamond alchemy has a very large stone grown from when he cleans or something.

It also sounds like you go a different route than me as well. I am cooling to 1c and allowing it to warm back up to 25c. rinse, repeat.

Day 6

So when I first started trying to make diamonds I was doing all kinds of shit, what blew my mind is I had a dehumidifier that was on continuous that I would set a jar or 2 in front of the vent witch had about 100 degree heat coming from it.

Now this dehumidifier was kinda fucked up as it would freeze the coil about every hr and go through a defrost witch would blow cold air out at about 35 degrees for prolly 20 min until the coil defrosted and then would go back to dehumidifying bringing the temp back to 100 degrees or so.

This was a jar that had sat for over night probably around 7-8 hrs in front of vent of dehumidifier. At the time I had no idea what had happened but this thread is making me think a lot more about the temp cycle that may have contributed to the ridiculous growth in such a short time.

Those look beautiful.

Thanks! I have yet to try again but as soon as I run again I’m gonna try a jar in front of that dehumidifier lol, at the time I didn’t have a clue about temp cycling but deff gonna give a couple more shots.

Hell yea! That’s a little more precise than a dehumidifier ![]()

I’d try something close to 100f for 1- 1.5hrs

Then 30-40f for 15-30 min

That jar I had grew faster in the timeframe than I’ve had yet still to this date.

I was the first to come out and teach people about temperature cycling. It’s scary how the details slowly disappeared between users.

Temp cycling requires you to bump off vapor and re ballast the saturation level for it to aggressively work. When we came out with the first glass vessel and explained this users were achieving great results. The process is as follows.

Begin at a cold temp and hold.

Increase temp.

Reduce temp and insert seed.

Raise temp and reduce temp .

On next cycle when you raise temp at peak temp you need to bump off pressure vapor through a trap of sorts.

Lock off and dip temp.

Raise temp and bump off.

Lock off and dip temp.

Raise temp and bump off.

When you make crystals grow the saturation of solvent goes down dramatically. You need to bring this back up by bumping solvent off to correct ratio Wich is usually the head space vapors under temp.

This increase saturation level as crystal grows solvent drops dramatically.

Without doing the swing and bump you will be struggling to slam seeds on bottom to spread and grow. Summit pioneered this tech while teaching people the correct way. This is called crystal morphology. It is done this exact way in every other process, and that process should be duplicated exactly for success.

If you do not have a safe method and vessel to do a sing a bump then you may just be creating unneeded challenges. In these pics it’s clear the process isn’t being followed b the results would be more dramatic.

![]()

![]()

![]()

that made my day!

I was just wondering when someone would get around to that trick (literally as I clicked on the link to this thread)

![]()

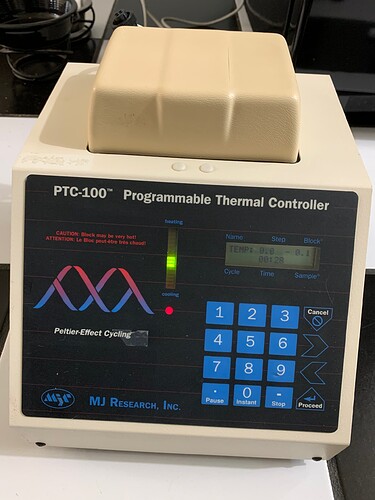

even grabbed a PTC-100 I see…

I haven’t been inside of one of those for more than 15 years, you might need to pot the electronics

I recall there was some glue in there that made the trick I was trying next to impossible, but don’t have any recollection what else I found…

…our lurker’s suggestion could trivially be accomplished with a PRV that burped every time you took the temp up.

Thanks the 1st gen the blocks just sit on there but these are glued. I thought about the gen 1 but wanted the newer version. Plan is to just sit jar on top and put min styrofoam cooler over the jar not the whole machine and if that works gonna buy more machines. This one was only $159 delivered.

EDIT: It appears I might have the 1st gen as what I thought was the 1st gen is just a heat block.

I assume this is the gen 1 you were referring to:

EDIT: Oops it appears the model in this video is not a PTC-100 even though the title says so as it looks like just a heat block with no cooling so maybe I do have the gen 1

just remember this is NOT an AtEx rated (c1d1) device. if you’re pouring late enough, it should be relatively safe…pretty sure there is a fan in there that dumps heat from a Peltier device…I don’t believe you can disable it and retain function.

I highly advise opening it up and potting everything that can be potted.

I didn’t find anything resembling an intrinsically safe replacement fan in the first five min…