I pretty sure this is the fastest way takes very little time to vacuum out

It s clean and you don t need to poke your arm in every so often to loosen up material for gravity to take over

The arm poking and sometimes wooden stick as extension is what made me desperate to find a different way

But hé you are invited to come around some time and give it a go

Invited regardless ![]()

You know that right !

Do like the hot recirculated n2 push, I need one of those, and a cold one too. First. Then hot.

Had not realized why machine made that request until just now. Just that it was “right”.

Thank you.

Yay for maths.

Suck baby!!!

I was always curious as to why no one ever used warm N2 as a final push to get extra solvent off the bio. Should also work rather well in rotating systems.

I don’t know if you’re just “blanketing” to atmospheric pressure, but depending on your setup, pressurizing the system with N2 to 1 - 2 barG might help accelerate the scrubbing due to partial pressure math nonsense. Cycling pressure would almost certainly help, but would be a pain to do manually.

If you wanted to get really fancy about it, you could probably put a hydrocarbon detector inline somewhere and use that to determine when you’ve hit your desired saturation/butane removal point.

that’s doesn’t strike me as far (enough) from the 405C auto-ignition temp…

Guess it s only to speed the purging of interest since recovering this gas is a nightmare with so much n 2 in the mix

As for centrifuges as far as I understand they are weak when it comes to pressure or vacuum

So not much to gain other than blanket

Put the thing on bearing welded to the sides like that old magnanimus closed loop . Your description reminds me of that nutty contraption with multiple “tumbler” vessels attached to a 160 gallon collection.

Nah I am happy with the solution

The tank was not designed for such actions the inner tank is 6mm wall thickness but the mantel is only 3 mm

So don t feel confident that will hold

And again there are only 6” entry holes on the unit top or botom so would not help much

The isseu was to much butane left even thou the unit was in vacuum deu to recovery pump ( corken)

With hot vapor N2 purging this is not the case anymore and it can safely be vacuumed out

Thx for the input thou that’s what this place is about

yeah, but how do you get your welder in and out through a 6" hole?

…and I was merely wondering why our robot with a bomb would make such a request…

![]()

![]()

so what we need is a membrane that will pass N2 and not butane...giving folks the ability to actually recover the solvent driven off in this manner.

![]()

another approach is compressing the N2/solvent mix into a secondary tank at say 20 bar, and pulling (pushing!!) the (~400ml) liquid at the bottom of said tank after an appropriate waiting period…corken should do it.

how hot is your N2?

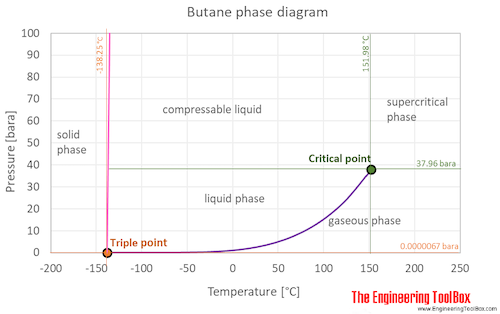

20bar will get you liquid butane at 110C…

saves solvent & N2

![]()

Sounds highly unlikely (for material compatibility reasons) and thus expensive. I did briefly look for membranes that would do an extremely similar job in the past and didn’t find anything that looked like it would be less than a mid six figure installation cost.

Standard N2 PSA membranes and such are fine with trace hydrocarbons in the atmosphere. Not necessarily so happy with butane droplets.

At the time condensing the solvent looked like a better option than trying to membrane it. But that was some years ago.

I like this.

Realistically, I’d be willing to bet that not a lot of heat is required to convince the alkane to bugger off from the biomass - it feels like this is primarily a recirculation/agitation driven process. So 10 bar and 50°C or less would likely do it.

That’s fuck all liquid - if one happened to be averse to waiting for things, a reasonably small HX with a cool to cold thermal fluid side would probably make this a relatively quick operation.

Or bubble the stream through some cool to ambient temperature water, which would cool it and also grab any water soluble nasties that had gone along for the ride.

Bang a hydrophobic PTFE membrane on the outlet, and when you’re done remove the pressure and apply some suck and your butane becomes a gas again and moves to wherever your sucker-pusher is directing it to.

Maybe this can be achieved by instead of directly blow out to the air

Placing a coiled and jacketed coldtrap and maybe a smaller cfm vacuumpump for final vacuum to avoid blow by

I honestly don t care for the valeu of butane lost more as an envimental friendly approach

Butane costs are negligible Since it s a subsidized good and 20Kg cost me

5.5 usd ![]()

Yeah, that and not having it in your spent biomass.

I hate pulling wet socks, then sliding a new one down into a fuel air mixture when im looking directly down the #^#^*!ing canon barrel.

Not quite the same problem you’re looking to solve, but close enough that your solution looks very attractive.

Yeah it a a wake up call

Guess that along the way I have witnessed more accidents than I wished and they make you realized

Yust one might work out differently

I am honestly amazed by the low amount of accidents in bho

Since there are thousands of extractors and many in garages

Including myself that got away with

Some risky ways for years

Have you considered a vacuum system that reach3d said dimensions like a stainless tricalamp elbow on central vac.

He IS vacuuming it out…

…but before doing so, he needed to get more of the butane out than the corken can reasonably achieve.

What vacuum pump are you using to hot cycle N2?

Sogevac 40 cfm

It go s in hot at the botom but by the time it go s treu the biomass it s cold warming up slowly

The vacuum system is a leaf blower

From the brand gardenia at first to load the vessel with 4” atex woodwork hose and a hepa filter box to catch the dust when unloading

Non atex but insulated with glaswool and epoxy

Considering of changing the unloading with a atex high pressure ventilator and a cyclone inbetween