Glad ya did it, man! Good on ya’. I like your approach.

Who’s gonna do it

https://www.researchgate.net/publication/239694252_Membrane_filtration_enhanced_by_ultrasound_A_review

Hmm, very interesting. How would it be implemented easily on a setup like this?

If I knew I would have come to the table with something more productive than “who’s gonne do it”.

I’ve seen two applications, One seems to be defouling the membranes, I’m assuming via reverse fluid flow and using ultrasound to encourage surface contamination to detach from the surface. There are a couple other journals discussing the turbidity of the feed flow and the effects of cavitation on the flow of the feed, but from what I can tell most of those are in relation to milk filtration and I think the filters they’re talking about are a nominally larger porosity than what you’re finding useful

Milk Tek here we come

Boosted up the system with a change of PRV today. Will be exploring some specialty high-pressure membranes in the near future.

As part of my new plan to data share, here’s a membrane trial I did today.

Membrane: SBNF from Microdyn Nadir, 1812 size. This membrane is made of cellulose acetate and advertised with a nominal MWCO of 2000 Da. The purpose it is advertised for is color removal (in water). The combination of it being declared for color removal, it being a chemistry I never tried before, and it having a high MWCO, led me to think it could be a good choice for a color remediation membrane.

I ran it at two pressures, 300 psi and 100 psi. At 300 psi, it permeated at about 240 s/L – with linear scaling, this would be 32 s/L on a 2540 – very fast. At 100 psi, it was 1/3rd the speed.

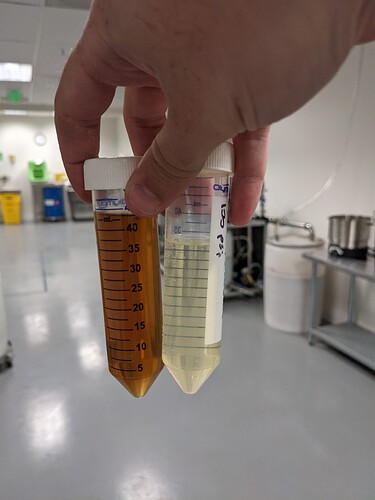

The color improvement was very encouraging. It rejected all chlorophyll, and almost all color of any sort. This is pretty good because i’ve found most all membranes to struggle with retaining chlorophyll in ethanol. A picture of the 100 psi run is below:

The strength of this color remediation is obvious, but did it actually allow cannabinoids through? Well, I ran in-house HPLC on the pre and post tincture. At 100 psi, the cannabinoid rejection was 75%. At 300 psi, it was 92% – so clearly, this is not really working right now for color remediation. At the high pressure, it is actually more like a solvent recovery membrane.

This is a good illustration of how MWCO are unreliable – this was rated 2000 Da in water, but is still rejecting most of the ~300 Da CBD.

Now, this brings questions to mind. The 100 psi sample actually did allow a sizeable amount of cannabinoids through, without color. Is there anything we can do to make this work a little better?

-

We can run at even lower pressure. We can run at higher temperatures. Both of these decrease rejection. Perhaps with some finagling, this membrane’s CBD permeation can be brought above 50%, and if the color remediation remains similar to what we’re seeing here, perhaps it could be useful after all.

-

Since cellulose acetate proved to have good ability to reject color, perhaps there’s a somewhat looser one on the market that we could try instead. It does not seem that Microdyn has anything suitable, but, perhaps there are some cellulose acetate UF filters that could be used from another vendor.

I’ll be trying 1. tomorrow, but these could also be seen as exercises for the reader. Love y’all!

Do you think running at 50% rejection then just adding more solvent is the way you’d run it? Until you get diminishing returns on diluting your retentate?

Are you running a decarbed solution?

This is non-decarbed. Rejection of only the decarbed portion was more like 60% at these conditions, while the rejection of acid was higher. 75% was the weighted average.

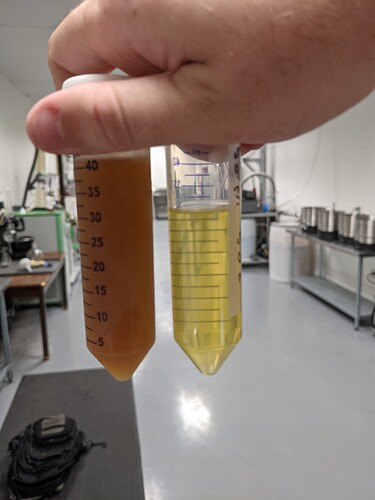

At a temperature of 50C, the SBNF yielded a healthy 66% cannabinoid permeation rate, while maintaining good color improvement.

Final picture:

Rotavaped, an orange, thin, high terpene type extract was yielded.

my reading of the nameplate

says the Haskel ex420 will do 1250PSI with up to a 600PSI pressure differential (4x drive pressure).

not sure how much flow that’s gonna get you though…

The pressure spikes are what will fuck you and foul your membrane

It’s enough to support an 1812. I wouldn’t say sufficient for a 2540.

Could a pressure snubber be used on this system?

Idk how much it would help tbh, pneumatic pumps are not meant for this application

Try it, I don’t know if it would work because I never use pneumatics

Your cautions should be held in high regard.

I would use NOTHING with a chinese pressure rating.

Pay for it…USA made, stamped and calibrated.

Can someone post a link to these high pressure rated stainless membrane housings? having a hard time finding some online.

Synder sells housings. If you want more details you’ll probably need to call and talk to a rep.

FYI Synder housings are 63mm nominal diameter. Some membranes are larger than that. Check with your membrane manufacturer before you purchase a housing and find out they won’t work together.

Domestically, Synder, and IndoFabs has actually been getting into it lately. Many international suppliers as well.