Hellow guys.

We have -80C chillers and 50L and 100L rotary evaporator in stock, factory direct sales.

DM me or send me email info@effison.cn if possible.

Andy

My God that joint between the primary and auxiliary condenser must leak like a sieve. I like the ball crane though

It is a flange connection joint, there is a PTFE sealing gaskets between the two dondensers, very good sealing man.

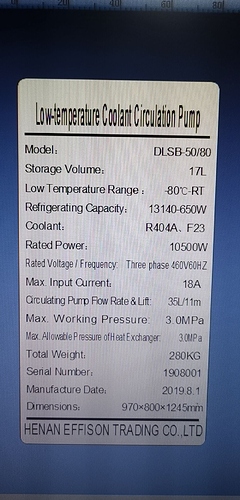

Whats the specs for the -80 chiller

Yeah… PTFE is not elastomeric so it doesn’t squish well. They always leak, but the bigger they are the more they leak. I’d like the large diameter except for the very small “bump trap” if you can call it that and the leaking joint.

There’s centuries of experience on this forum, I think you would do well to ask and really listed to the features and problems of interest when designing future products.

I’ve given my critiques but I really do wish you the best of luck!

This one is the most popular model 50/80, here is the label.

We tested it with a 150L tank with ethanol inside, can cool it down at -60C in 1 hour, at -80C in 2 hours.

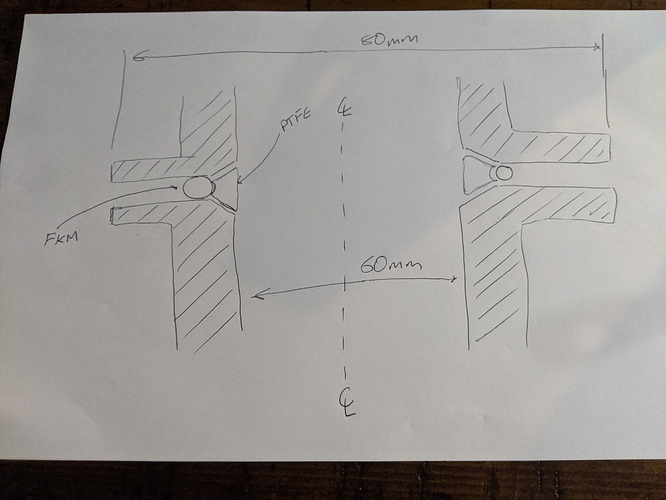

Thank you for your suggestion, here is the pic of our sealing, it is a rubber ring covered with PTFE. We improved the sealing from 2017, feedback is good.

Here’s the issue with these rotovap seals: there’s only 15psi max pressure applied. Because we want PTFE for chemical resistance, we use a plastic which requires a large amount of force to fill the gaps in the glass (there are always gaps because of manufacturing). We can’t exert enough force with vacuum or with clamps because the glass would break.

The reason KF style vacuum fittings seal better is they make contact on a smaller surface area so they don’t need as much force to seal. I wish someone would make rotovap seals out of FKM that were more like KF joints or knife-edge vacuum joints for this reason. I can almost guarantee that if you made a rotovap with this style joint it would be preferred.

The larger the joint the bigger the leakage problem is.

Here’s a little video from today actually:

I see, have to discuss with our glassware factory, as I know it is not easy to make a glass KF style joint, we d like to try the Spherical joint.

I think that designing a PTFE or FEP “centering ring” with FKM O-ring would be sufficient in the standard style rotovap clamp joint. The smaller contact patch of the O-ring versus the flat gasket makes the force more effective at producing a seal.

I’ve never used a ball joint with a gasket like you’ve pictured but I think it would work well. I imagine they are difficult to manufacture to good tolerances at large diameter though

Here is a picture of what I had in mind, I think it wouldn’t be too hard to make:

Interesting, will discuss with our engineer about your drawing

Are these stateside? Prices? More detailed power specs on chiller?

So it has 650w at -80?

Yes, it is 650C at -80C. Three phase 460V/60HZ. Price is USD7900

Two stages compressors, 6P of each.

Three phase 460V/60HZ. Price is USD7900

you’ll like it more when you turn @BG305’s age and require one to get your sac in the tub.

With my sketchy lab practice I’ll be lucky if I have any left when I get to crane age lol

It is a 100L ball, hard to lift it with hands

Thats what she said.