It has PTFE in it but is not completely Teflon. The mixture enables the low temperature rating and multi-use characteristics. We have used them for many years now and will be the only gasket we supply on our units.

Better than tuff steel?

Oh yea… -346F and multi-use. Did I mention cheap?

GYLON BIO-PRO® seals offer a safe solution with its modified and restructured PTFE material, pre-formed and stress controlled, for all Tri-Clamp® standards. Manufactured from our proprietary GYLON® style 3522 modified PTFE, GYLON® BIO-PRO PLUS™ delivers best in class performance across all critical factors such as compliance, chemical compatibility, sealability, creep and cold flow. The new Style 3504 GYLON®Stress Saver® combines these proven sealing advantages with the performance characteristics of the industry recognized GYLON® 3504. GYLON® Style 3504 is a PTFE Gasket with aluminosilicate microsphere filler. This style gasket is widely used in glass-lined flanges and other light-duty flanges where available torque is limited.

Also has an excellent chemical compatibility. We have definitely put these gaskets to the test with low temperatures and swings from hot to cold to hot. Check torque specs, each gasket type is different.

we’ve been using the same set for a few months with no issues, never used tuff steel

Tuf-steel are stupid expensive and technically are only rated for one use like pure PTFE. Gylon has a stupid high re-use rate and are about the price of Viton.

This matches my experience: Over torque them, and they’re incredible expensive, leaky paper weights

I love envelope gaskets. If I knew you IRL, i’d honestly hand you some to try. They’re cheap and reliable.

well shit I may have to switch to GYLON

I use an envelope gasket to hold my injection port to the top sight glass, only envelope gasket I have on my system but I feel like I trust that one the most. Everything else is all ptfe gaskets. Except my tank. My tank is buna.

How is their vacuum rating at high temperatures? I know it’s a hard question to answer, but since they have such a high temperature rating, I would imagine they are pretty good since they have such a high temp rating.

Also, can confirm, PTFE gaskets leak like crazy!

We have never had any real issues with them. Regular PTFE are horrible and extremely leaky. Gylon are still fairly rigid but they have a soft surface that seals pretty easy. Don’t require high torque to get a solid seal.

I think normal PTFE gaskets work better warm, anecdotally: the only time I successfully sealed a 6" PTFE gasket, I boiled it in water before seating it. Don’t recommend, but hey, it worked.

I’d like to think the Glyon would be even better. They’re definitely on my list of things to try, appreciate you bringing them to the communities attention @Zack_illuminated

It seems like gylon and tuf/tef steel still have the same thermal properties as PTFE to be stable at ~250C. I’m going to do gylon just because it seems better to be compressible at room temp

Hi all, I am new on this site.

Recently purchased a NOS diffusion pump, manufactured by Torr Vacuum Products Inc.(california).

TVPI is closed since '90, so I am after the tri clamp type for the foreline connection 2 inches OD.

It seems not fitting in any standard…

Somebody can indicate what type is the used ferrule?![20220818_085303|375x500]

How can I share pictures here?

brand new accounts don’t come with the ability to post pictures.

IF TVPI used other than a standard flange, then it’s no wonder they went out of business…and I’d be willing to bet they did not.

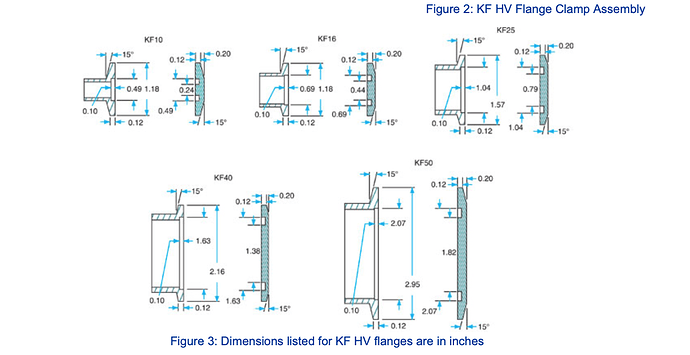

chances are your looking at KF50.

see :Kurt J. Lesker Company | KF (QF) HV Flange Technical Notes | Enabling Technology for a Better World or the all gnowing one for more

edit: just re-read. OD ~2" is likely KF40

Its not listed on your site, but thought Id ask if you offer 8" gylon gaskets?

Thanks

Hello, did you finally find out what flanges are used on the 126080 diffusion pump?

I wasn’t able to test it while distilling, but when dry i was at 150 and it got me down to 50 um hg. I recently tracked down a pinhole leak that took that 150 down to a 50um.

Shelved it a while ago, but now that my elektrickery skills are much better, I’m going to give it another crack this weekend.

This pump oddly enough has a normally open safety switch so I’ll have to work around that with a board.