Merry Christmas

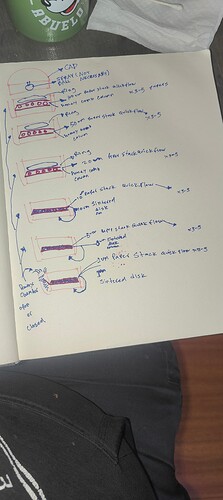

Remember guys, give the columns a little room on top and bottom so it can “channel” through/flow and not come crashing through. And you don’t need to run at crazy pressures either. ![]()

Safety first

Tampon tek ftw

If u have a seperate holding vessel for u to dump the column in then the tampon tek is a life changer.

forsure just get some smaller micron socks so none of that plant matter gets threw

We use a layer of cotton balls between the sintered disc and the media. No more clogging or flow issues.

Just any unbleached work?

Yes. Not a bad idea to use organic, but the non-organic balls we have we had tested for banned pesticides before we used them. All were ND. YMMV.

I never had issues with granular media is this happening with powder media?

this works really well! we sent out the cotton balls for lab testing just to make sure there was no pesticides or anything like that on them haha

Sintered disk filtration really should only be used on crc and never stacked… Old methods die slowly.

The 50um socks keep the bio out.

I use a 10-20um sinter on crc and a 0.22um 10gpm post flow to clean up the rest that all the product flows through as well as a 1um upstream of the crc.

We offer both our filters and filter housing’s. Lots of options. 1um absolute that filters down to 0.01um at 98%, high flow antimicrobial, etc.

Filtration should be staged…exactly how depends on your particle size distribution…

Yeah but not with sintered disc…

High flow cartridge. How many gallons per minute can you push through a sintered disk at 30psi?

The answer is not much at all… Or you could be never dealing with clogs and cranking at 10gpm all day long.

Don’t need replacing or cleaning often either.

Edit: the R600 Behemoth moving 30lbs a minute of propane is only 7gpm.

I’m certain we could come up with a scenario where staged scintered disks would be appropriate.

I absolutely agree that “below one’s CRC” is not that scenario.

However, I vehemently disagree with teaching folks NOT to stage their filtration…(but I had that beaten into me by someone who dug into filtration deeply during her PhD).

What diameter?

What micron rating?

Size matters…but size distribution is key

We do staged filtration on both just the solvent and just the extract.

1um-0.01um absolute, hydro, 50um bio, 1um crude, 10um crc, 0.22um final removal. Only the 10um is sintered disc on crc.

Doesn’t really matter, no one is doing above 6"crc typically and smaller dis provides less flow.

Edit: I’m not saying don’t stage smaller micron… Instead only don’t stack sintered disc.

If the particle properties could be specified for a filtration, the target properties would be for the particles to have as large a size as possible, be as near to spherical as possible, and have a monosize distribution. Their largeness would minimise the interactions at the particle–liquid interface, minimise the effects of ageing, effectively eliminate many cloth related problems such as bleeding and blinding and the need for very frequent cleaning,

Pity that’s not how the real whirled works…

The particle size that is most important for characterising a filtration is rarely the mean size (50% size) in a distribution; the finer particles in the distribution usually “control” the filtration, and when comparing the likely effects of particle size on filtration it is preferable to compare the 5 or 10% sizes. Even small increases in the number of these finer particles can significantly reduce filtration rates.

As I would expect someone with your expertise to…

I’m just here to make sure folks like @Jock4200 don’t misinterpret “no need to stack disks” as “filter it in one”.

Although I’m not sure that folks as sophisticated as @Jock4200 would make it this far…

Disc filters are cheaper than the cartridge housing, but the thing people never really factor into their cost of goods is downtime not extracting because you are cleaning filters or clearing clogs.

The amount you save by buying sintered disc is lost exponentially as you use them.

Preaching to the choir. We are only running them on our incoming solvent….pre-distillation.

Low flow and low particulate loading application…

I want to know more, please show me, I currently stack sintered discs and use powder media such as b80. Your link does not lead to any kind of filtration equipment.

Talk to me goose!

Yeah, you really only need a 10-20um to get the majority out and hold the pack then send it through the high flow antimicrobial. We have a few different filters and housings to go with them. What exactly are you looking for?