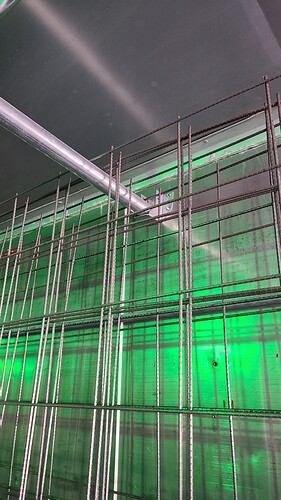

Here is a reefer I use for drying.

I like the idea behind the racking setup.

What are the two grey boxes mounted above the dehy unit? It looks like they are mounted on the container doors, so I assume you pulled out the refrigeration unit on the front end and replaced it with a man door or something along those lines?

How much product can you effectively dry in there?

Yes, it has a 3 ton HVAC unit now. I can fit about 3 containers into it if I pack it tight on those hanging wire mesh racks. Those are used in concrete slabs.

Looks like the ac Bub

Maybe a rheem air handler

Yeah it’s a reefer container but the fan on the back of the unit is way too powerful so we had to cut holes for the rolling A/C units that we put in the room. It’s not ideal but it works for our situation. The room is never 100% full so we can afford to have them in there. I’d much rather have a unit outside of the container.

Unfortunately, I can’t post pics but the setup @bg305 is using looks pretty solid. If you want to get really OCD with it, you can hang unistrut from the ceiling and use it with steel tracks and track hangars. Just be sure to orient your hanging racks in the same direction as bg’s so that loading, unloading, and cleaning are easy. If you orient them the length of the container you lose a lot of space to the aisle.

Because we have so much air space due to the room never being over 50% full maintaining humidity is a bitch. Each ~40 foot flower room (also containers) only takes up a third of the dry room. Definitely calculate the space needed for your drying very carefully.

When we fill it I have to run a 180pt and two homedepot dehumidifiers to keep up with the moisture. Also having a 3 Ton helps being able to keep the room at 50* while drying.

Damn, how’d you get it down to 50° without it freezing up?

Mine won’t go below 62

Correct charge for the temperature range

This ![]() I use super heat subcool to charge not pressure. I run all my room at 50* in late flower also.

I use super heat subcool to charge not pressure. I run all my room at 50* in late flower also.

TESTO 550

Why don’t you split/seal the container in half? 8x20/10x20 is well enough to dry 15 imo. One of our dry rooms was about 5-6ftx20 in length. It was always packed but was more like 22-25 dry.

That gives you 14 days per side either way. With no difference in efficiency of the dehumidifiers and separate environment conditions for whats recently harvested vs whats almost out.

Hello

Im building out a few 40ft containers for drying only. We got murdered by mold last season unfortunately. Would like to pick your brain about the set up. Would appreciate it a lot!

Thanks

They were looking at doing just that before I was hired but I think the idea got set aside for other larger projects and was forgotten about. 8X20 is definitely enough space to hit like 25 pounds, even if we weren’t going all the way to the ceiling. It’s not a perfect setup but I’ve found that even if they are just a touch too moist all I have to do is be religious about burping and turning the buds so that nobody on the bottom decides to rot.

Luckily, in the entire 6 months of being at full production we have only had one minor botrytis issue (5 grams out of about 250 pounds) because the crew overloaded the totes. We have some Elitech data loggers that I toss into each tote and it usually settles down to ~60% within two or three days from breakdown.

Agreed. I dried 65lbs last season in a 10x20.

If you bring a bunch of wet material into a room with dry material it will most definitely soak up moisture and probably the smell of chlorophyll.

Make 2 zones if you need to stagger harvests and overlap dry times.

That botrytis was there before the crew “overloaded” the totes. Also, that whole tote was infected not just 5 grams.

Can I ask how your bosses pull down 250lbs in 6 months and not have the money for proper drying rooms?

Oops wrong thread

do you put a coating over the raw steel on the remesh?

Correct, spores are generally everywhere, especially with this facility’s location. We just gave them the conditions to grow. Trust me, the crew “overloaded” the fuck outta these totes, zero head space in a tote is no bueno. Our state does double microbial testing, once in bulk flower and again in finished package. That flower passed at 0 cfu/g because he botrytis was barely formed on the nugs we found it on. We haven’t spent the money on splitting the dry room because it isn’t really a problem like I initially thought it would be.