First when i started making extractions I read somwhere that butyl acetate should work as a solvent. I extracted with the BA and wanted to filter it through a sterile Filter which is made of PE or PP. After about 100 ml the filter process stopped and I had no idea why. After a few more minutes the filter dissolved. I was left with a mixture of BA Cannabinoids and PP. I evaporated the BA and didnt knew the Vapor is heavier than air then the whole BA dropped to my heat source. I was scared that something will explode. Then I put the mixture outside to let the sun help me. After all the solvent was evaporated i was left with a mixture of Plastic and Cannabinoids. that was pretty cool though. Unfortunately I had no Idea how to separate this mixture again. In the end I had a solid piece of PP or PE with the extracted compounds in it. Would be a cool way to smuggle if you have solid Plastic pieces with Cannabinoids etc in it.

What accident/guy?

Check him out on Instagram, dude is a survivor…. His account is Apollo_dabs916

I had a 1.5 inch tri clamp ball valve that was laying on my extra parts table in the open position for months. Was getting it ready to be put back on my system so brought it over to the sink to clean it. Cleaned the inside then went to flip it to the closed position so I could clean the ball valve piece. Thats when I got a nice sprits of butane and bho into my eyes. Seems butane was trapped inside the compartment that houses the ball when in the open position. Something to keep in mind especially when working with more hazardous solvents or bigger ball vavles .

you mean like…

This is several years old. I was running propane, hot, so there was about 100 PSI of pressure. The 12 inch clamp had a stripped nut, so a small leak was noticed once I moved the 10 pounds or so of propane extract into the recovery chamber. I moved away once I noticed the nut was stripped, and luckily avoid injury (there was slight discoloration of the skin around my left ankle around the top of my sock which had become soaked with propane for almost a year). I am most thankful for the luck I have had.

If you are working with really high pressures, please always anticipate parts flying and swinging at high velocities. I had the extraction machine tethered so it was being pulled on away from me, and all parts were not near and especially not under any lights. I would certainly be dead if this had taken place under a light source. I am most thankful for all the good luck I have.

Also, you never know when something will fail you. When you have the chance, take the time to think about it. Do not break the rules when it comes to electronics. Do not do what I did, and say your good, fix the machine, and get it back up and running the same day. See a doctor, and get some help. Even if you need a couple weeks to decompress and asses almost dying, because your employer doesn’t care once you say your good.

Very lucky and loving life.

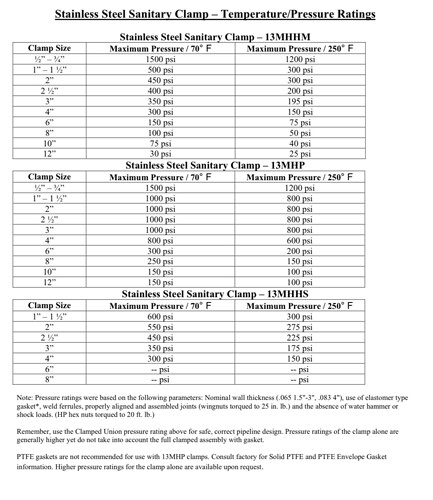

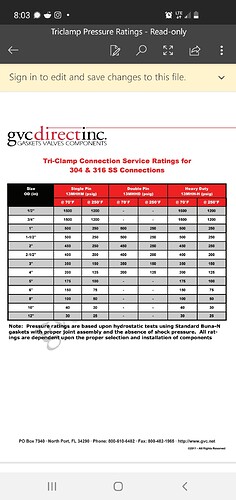

Glad you’re ok. I just had to tell a buddy that his 12 inch clamp is not ok in a Closed Loop. 12 inch is rated for like 45 psi or something crazy low

More like 150psi at 70°F and 100psi at 250°F for a 12" high pressure tri-clamp fitting.

Interesting maybe they made this chart for liability purposes then?

I still think anyone using a 12 inch is asking for trouble

That’s because the chart you shared doesn’t list a high pressure dual bolt 13MHP clamp.

Well 150 psi is not safe for propane so it’s still not a good idea

Totally agree.

Oof nightmare fuel. Glad you’re alright.

Wish there was an easier way to push people to safety that pursue it. It’s a personal goal.

If you ever run into another stripped nut mid run, the solution is to add another nut and tighten them both, this saved the day once when I had butane pouring out a clamp that ended up having a stripped nut…

Yes proper inspection could potentially be the best solution, sometimes we don’t get best case scenarios and have to adjust on the fly

I had a helper once who vacuumed down the system after a run to switch sands in crc. He took off for lunch and didnt crack a valve. So it pressured back up to mayb a lb? He didnt look at gauge and unbolted and opened top of crc. The sands flew every where completely coveing hin and the lab lol. Lucky for him he had a full face resperator on that day lol. I was in my truck smoking so i escaped the dusting ![]()

Always watch ur gauges

I grew 99 plants both outdoor and indoor in INDIANA every year for about 10 years. The good old boys said I had balls of steel.

I remember the corn field owner chasing us down his access road while we stripped the last plant off the stem in the cab of a U-Haul and threw the stem and root ball out the window. That was the closest to ever getting caught for me.

At the first facility I worked at (mmj in the state of DE) we made MCT tinctures and ethanol tinctures. pretty simple process, we used the good ol magic butter machine, put in the weed, put in the mct/ethanol, and start. It was easy enough, we trained some packers on the process.

One day one of the packers, instead of adding ethanol to the magic butter machine, added METHANOL instead, and turned it on. No one realized until all the methanol evaporated, and the weed inside was beginning to smoke. Could have been very bad, but no one was hurt, so it was brushed under the rug… good times.

We had a co worker get impatient when waiting for a run to off gas enough to take off the collection pot and pour into a miner. Myself and our other partner told dude multiple times to not take it off and just wait a bit. I walk in to start loading the next run as he takes the pot off and starts walking to the venthood, to much movement agitated the solvent/material and it literally erupted out of the pot (was already to gassy to deal with). Dude also had no PPE so got a face full of it straight to the dome. ALWAYS WEAR YOUR SAFTEY GLASSES AND BE PATIENT is what we learned out of it. His lip was blistered pretty good and had to use a neti pot to literally get the dabs out of his sinuses. This particular run was a mixed batch of Randy Newman x Cookies & Cream so we gave dude shit for awhile about how he took Randys whole load straight to the dome lol. Dude took a few days off after that one…Processing: 20220412_100951.mp4.3gpp.3gp…

There is a big amish community in Michigan and they work relatively cheap and faster than you can imagine when it comes to putting up a barn or something of the sort. We let them drive the skid steer once with the forks on, they completely front loaded the weight and the skid steer was almost completely vertical on the ground with the forks in the ground and the door swinging open towards the ground.

Nobody got hurt, but it was ridiculous to see. Don’t let the amish operate heavy machinery, even supervised.