Ok, makes sense. i’ll do the double boiler method then, the sous vide machine i have now only goes up to 99C.

It should be mentioned if you go the double boiler route and you choose water as the heat transfer liquid you can only reach a temperature of 200°F(for the water your solution will likely barely reach 180°F) which will also increase the amount of time you need to spend at this temperature to completely decarb your material, you will now be in boiling water which will still require a lid to protect from water mist coalescing into your jar, and with a lid will likely get bounced all over the place since there will be air in the container unless you were working with a decent amount of oil

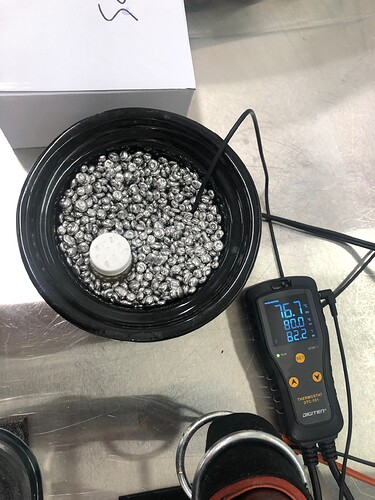

My preferred method, generally only worth the additional transfer loss, and setup and teardown procedures when working with batches of more than 100g is to use a double boiler where the water has been replaced with oil or sometimes even sand, more commonly referred to as a heat bath, paired with an overhead stirrer, and a thermometer of one sort or another.

Using oil you can achieve temperatures high enough to get your solution up to 250°F which from my experiences has proven to decarb efficiently with very little degradation when paired with agitation. At 250°F and around 500-1000rpm depending on solution depth you can almost completely decarb an entire kg in about 4 hrs time and go from a starting material that tests above 99% THCa to an end product that is over 90% THC and less than 5% THCa.

TLDR: Oil is better than water for decarb baths. For such a small amount I highly recommend a standard oven in a closed jar that isn’t more than half full for about half a day with an ir thermometer pointed at your solution, not your jar, to ensure your solution is actually reaching 250°F and set your oven to whatever temperature gives that reading. If you still see tiny bubbles when back-lit, go longer.

IMO hotter is ideal ONLY if it’s precise and repeatable (accurate is nice, but not as necessary). Which requires more gear than achieving 100C consistently does.

Totally agree that hotter gets the job done faster and more efficiently. Even agree on the temp.

I’m using a silicone based heat transfer fluid and a heated circulator. Last I checked we were running at 120C.

IF you’re into that sort of thing, it IS pretty simple to make a controlled temp heating bath using a thrift store crock pot (I’ve used a counter top roasting pan) and a cheap PID controller.

The trivial implementation uses a plug and play controller such as https://www.amazon.com/Inkbird-Max-1200W-Temperature-Controller-Greenhouse/dp/B01HXM5UAC

With sand or beads in there, there will be a temperature gradient. Using oil has its pros and cons. I personally find that oiling up my glassware then getting it hot tends to decrease its lifespan…

wow thats pretty cool. maybe I’ll use my deep fryer and let it sit in for a while hahaha but I’m not sure how accurate the thermostat on it is, it should be pretty accurate. I can just use a handheld thermometer though.

I would just use a nice heat gun with the oil in a small jar or beaker, while using a dab tool to stir. You can get past the threshold of crystallization with a partial decarb which will also preserve your flavor. This can be achieved in about 30 min

If you’re not going to go for a full decarb you can test if you’ve taken it far enough to prevent crystallization by throwing it into a refrigerator for a few days.