I dont have my n2 setup going yet. I don’t know the nitrogen psi to regulated psi conversion of 1800psi. But yes cold and fast sounds good for that.

I will set my regulator low to start, 25psi? Tank will be in dry ice but wondering if using an injection coil in dry ice and ISO is redundant , I think it will be better , as to ensure solvent temp for about 10 lbs of solvent.

How much n2 pressure is dangerous, no prvs yet, but purge lines on all vessels

I wouldn’t do it without prvs. Don’t risk an explosion!!! PLEASE be safe.

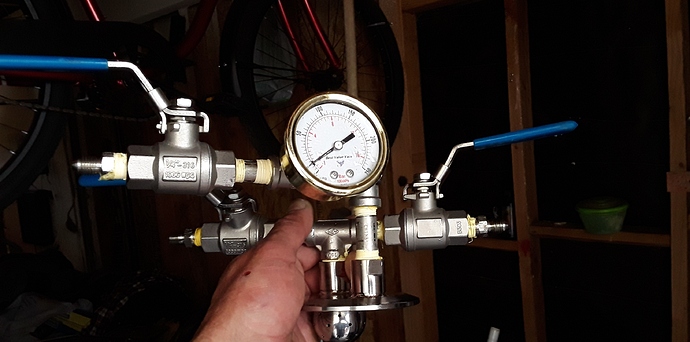

I’m still building my nitrogen setup. I’m going the extra mile and taking @Killa12345 's advice and putting prvs everywhere nitrogen can possibly touch.

I’m scared half death about something going wrong and you’re over here with no prvs. Smh man

I can purge my vessels, gauges on all, my financial situation i can’t afford prvs yet, i want them on all vessels, yes @Killa12345 is the man with parts i need, my first live resin run, so i want to ensure good solvent pressure and flood