No there’s no way to really do one on those. Auto tune is about half usefull on cheap china pid bc those are variance based pids. Glass col is voltage regulation bias to temp reading via thermocouple resistance and our mantles that auto tune are full software interface and not built in pid variance pid settings. Auto tune is basically the cyclic form of reaching the p,I,d, values for the pid to control the digital controller. Our auto tune is misleading it’s not exactly a pid auto tune it is highly advanced and designed specifically to attack agressive heat mode applications.

Thanks for the tip. Never tried it myself! I remember reading about it here on the boards.

I’m surprised that controller doesn’t have a power dial or built in variac to adjust power.

Would a variac between the controller and mantle help with the wild swings?

I would think in the case of straight “plug and play”, a variac inline could potentially cause more confusion here. More than likely the controller is a simple on off switch that is taking temp deltas/ramping into account to some degree. Again, I have no experience here, but my guess is the autotune works to adjust the frequency of the switching with a typical flask load and target temp range for your workflow.

If the controller is dropping temp it makes me think the initial heating frequency is short on with a long off cycle. If thats the case, all the variac can do is adjust the power of the on position from 0-100%. In my mind, using a variac would translate to your flask temp constantly dropping still, but ramping back up to temp slower and not overshooting (as much?). Unfortunately, I think you would still be dropping below your target temp range. I believe the only real solution here is configuration via autotune.

@dp621 exactly. The mantle i think is putting out too much power to heat the boiling flask. By the time the probe inside the flask gets to set tempreture, the mantle shuts off and all the extra heat stays in the mantle for a while until the temp starts to drop. Once it drops below set point, the mantle turns back on and takes a while to get back up to temp and has to increase beyond that while the boiling flask gets up to set temp and the whole process repeats itself.

So there has to be a setting to control the amount of power the mantle is heating up with instead of the “balls to the wall” setting.

i think the opposite would happen, it will lower the power on cycle therefore creating longer “on” time. this might make it more stable. i would attempt to test it though.

Have you tried adjusting the power output? I believe the controller with it has a little power output that relates to the size of the flask. The different size flasks, material loading, environment temperature, etc can cause the PID to be temporarily inaccurate so they made a power output knob to deal with that. PID’s will adjust given enough time but adjusting power output or doing an autotune speeds everything up.

@square_root_pharms, you are correct. With the clarification above your post from op that makes the most sense. I was going off the 10C drop from set point in the first post thinking there was a ramping problem with the pid.

I just found the manual earlier and saw that the controller does indeed have a power output % and was on 75%. I lowered it down to 50% so we will see if that helps along with the Auto config.

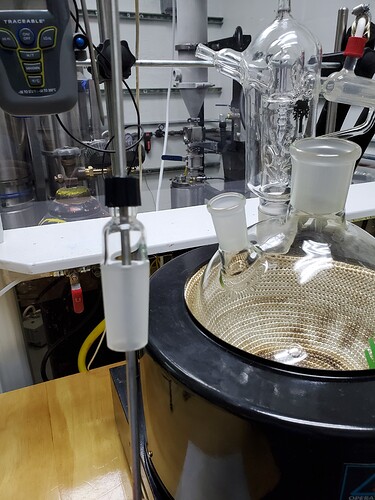

I had the same problem. I would try getting rid of that glass thermowell. I switched to this one and now i have 5° average temperature fluctuations. 2.5° above my set point and 2.5° below my set point. Q

Also i would set it so that the temperature probe is maybe a half inch off the bottom of your boiling flask and as close to your stir bar as possible with out hitting it.

There’s a possibility that you’re thinking too much when it comes to the heat fluctuations and vapor temp control.

I think that turning down and up the stir bar in order to control vapor temp is probably a bad idea. Stir it up and let the fraction exit. It sounds like what you’re doing is sort of like charging up the flask to temp and then preventing the heat from exiting via boiling/vaporization.

Do you know how long your first pass took and how it tested? Was the testing of the first pass oil okay or was it low potency already due to degradation, rather than bad separation. The notes on the second pass run look fine to me when it comes to temps and times under those temps

Edit: reducing the heat rate will help too

That’s standard for glasscol. What’s happening is your Distillation is sub cooling the reaction. This in turn triggers the process. I have solutions for you. But it’s not with using that hardware. We have digital software that catches this before it happens and maintains heat. Also the glasscol uses a smaller heating area so it has to get really hot before it transfers the heat to fluids.

Farther away from stir bar actually.

Lol. I knew someone was gonna say that. Mine is about the same distance from the wall of the bf and the stir bar. Almost right in the middle.

All i know is i had the same problem and this fixed it for very little money.

I see what your saying but that’s not the main problem. And, as stated in my original post, our first pass comes out between 58% - 68%. Second pass is not that much higher. I don’t think degradation would be a problem since we don’t ever go up to 200C with our low micron level. I was using the stirbar to prevent the vape temp from dropping 15C+ and overshooting the same range.

I appreciate your feedback.

Dude hell yes. Ill try this out once we try to auto tuning.

Got a reply from Glas-Col about the controller,

“Thanks for your inquiry. Have you auto-tuned the unit to your process?? Make sure the sensor in close to the side wall of the flask. Another option would be to turn down the power output from 100% to 70% for starters.”

Our output was already at 70% so turned it down to 50%. I think ill go ahead and also try the Layboy glass thermometer with the autotune.

You can end up with degradation at low temperatures and low vacuum if the distillation isn’t happening fast enough or if the head is designed poorly without degradation in mind.

I missed that you posted first pass potency. 58-68% is pretty low potency for first pass. We generally see 70-80% even with pretty low potency crude.

Degradation would explain why even after separating the non cannabinoid fractions you end up with low potency. Did you post the COA you received?