@anon42519203 Using valves as to close (making smaller) the orifece so the amount Capable of passing treu lowers ?

I have worked with hundreds of AC motors and VFDs and such in my career as control systems engineer.

The torque of the motor can be obtained from a data sheet for the motor if you contact the manufacturer. The peak torque will fall into a band specified on that data sheet. Generally the motors on a VFD operate at a constant torque mode up until a point. Horsepower is simply torque multiplied by RPM and the motors operate in a constant horsepower mode after they reach a critical RPM. Since horsepower equals torque times RPM then mathematically torque must fall off as RPM increases. So once past a certain RPM the horsepower remains constant but torque falls off a cliff on the charts as the motor transitions into constant horsepower mode.

The problem to cope with on a VFD is owing to electrical slip of the rotating magnetic field at lower RPM. When the electric field slips it generates current in the motor at unwanted spots and this tranlates into heat. So trying to run these motors under load for extended periods at low RPM causes heat build up not normally seen on a standard motor. This means that unless the motor is specified as a VFD duty motor that early malfunction rrom excessive heat is an issue.

VFDs have utility when extremely precise motor control is needed. Most motors run at 3450 rpm which accounts for slip of a 3600 cycle you would normally have from the standard 60 hz motor. VFDs change the frequency so that the magnetic fields used rotate at a different RPM than 3450. VFDs are also useful for converting single phase input power into a three phase motor if needed although at a reduced horsepower rating. This is possible because when a technique known as pulse width modulation (PWM) is used in a VFD as the means to control voltage then that voltage must first be converted into one central power bus. All AC power from each input phase is converted into DC and stored on the bus. The VFD then slices off just enough power to create each phase of motor power and using pulse width modulation then creates the sine wave in AC that each motor phase needs to see. For single phase input power simply wire the single phase input power with a jumper so the VFD “sees” power at each input which it then converts to bus voltage.

For a vacuum pump application I am uncertain what advantage is gained by using a VFD that cannot be achieved without valving. VFDs are notoriously vulnerable to bad input power and also if more than one VFD is used in a system without installing both line and load reactors (3%) then you will be plagued with nuisance faults because this will be sensed as a voltage error.

I have designed many systems around VFDs but also worked around the RPM problem using outside means which is always preferred. The odd thing anout VFD systems is how picky one VFD can be about incoming line power quality while another right beside it is not. VFDs can be used typically up to 120 hz as well but as mentioned the torque drops like a rock after the motor hits its design RPM. You are asking though about a low rpm situation so I focused on that.

Thank you @Beaker!!

good thing we be running -60C ethanol though the pump head then ![]()

Yep thats it

@Beaker, any advice for connecting single phase power to a 3 phase, 15 pound capacity, 2.2kw centrifuge using a VFD?

@beaker is not among us any more sadly

![]()

did it come with the VFD or are you adding it?

RTFM and go for it? Most if not all VFD are up for that task.

or buy that clue from someone who does it for a living…

correctly programming the VFD to use a braking resistor so it slows down in a reasonable amount of time is a handy trick. I need to figure out how to do that on the unit I’m running right now…its all well and good to have a 6min extraction cycle, but if it takes another 4min before I can open the fuge, I’m wasting valuable time (here, as you can tell ![]() )

)

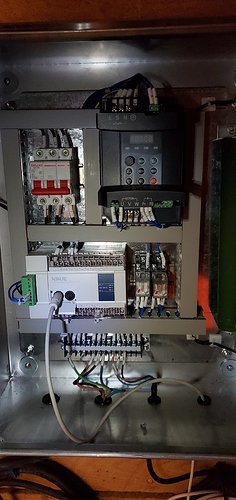

I bought a VFD and I’ve read the manual, but I think I need to read it again and buy some additional components to make it work with the control panel that came with the fuge. No point in having the VFD if I have to manually tell it when to reverse. Here’s the guts of the fuge wiring panel now, with an inverter to change AC to DC power for the control panel.

Is this a single phase in three phase out or a three phase in three phase out?

would love to hear back on how this goes.

it’s currently over my head…but I’m working on solving that.

The picture currently shows 3 phase in and 3 phase out. I used a generator capable of producing 3 phase power to get the operation running while we figured out phase conversion but I’m ready to ditch the generator and get power from my main panel, which is all single phase.

I believe I see three phases on the input side…

You just need a single phase to three phase programmable VFD… black brown and blue power the motor, green ground, and I would go with cyclo…

I never reverse…

spinning backwards isn’t necessary all it’s made out to be.

for me the VFD is so I can turn it up to 11.

or 15

cannabis is fluffy

![]()

Edit: as in you’ve got 15lb in a fuge nominally rated for 25kg. there’s math somewhere that will tell you just how stupid 75 or 95hz really is. You do have a mezzanine you can watch from right?

We’re getting close to the point where we can run some experiments to determine the benefit of forward only versus cycling between forward and reverse, plus of course playing with pre soaking times, number of washes relative to CBD content, blah, blah, blah, science, blah, blah.

Nope, no mezz right now, someday that’d be great.

talk to arometrix about this critter (not cheap list is like $8k)

it will make that optimization way easier…

I don’t know what that is, but I think I want one, and it’s nearly Christmas, so it may make a good self gift. Alright, it’s past my bedtime, 1, cause I’m old AF, and 2, I’m an east coaster. I’ll reach out to arometrix about that piece of equipment. Thanks!

Edit: $8k ![]() , probably not in the budget this year.

, probably not in the budget this year.

yeah, not cheap. but probably economical. compared to most other In House analytics options or third party testing

assuming $80 for each third party potency test during R&D, it doesn’t take long to pay for itself.

Caveat: I was among the folks that asked for Arometrix to build it…and mine hasn’t arrived yet.