No worries! Your advice so far has been spot on and I cant tell you how much I appreciate it.

I think the thermo in the head not working properly is kinda forcing this to fail. Posted a few pics above.

No worries! Your advice so far has been spot on and I cant tell you how much I appreciate it.

I think the thermo in the head not working properly is kinda forcing this to fail. Posted a few pics above.

Blue is azulene

Green is chylorphyl (need to winterize better).

You should be able to be under 50 micron dry run! Definitely the most frustrating part of SPD is chasing leaks…

I got small leaks and I’m not ever over 50 microns by mains. Hit me up but I’ll walk ya through it.

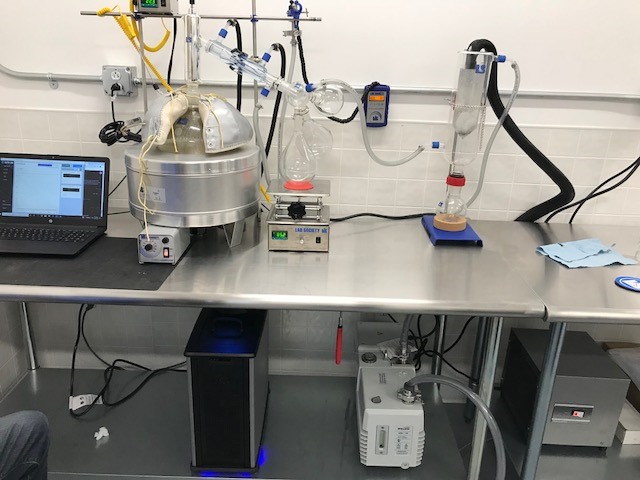

There are several things that seem off on the pictures

Please send one at a distance to have a better look

Looks like vacuum lines are long

Hey all, we are back at it today. started with 700g of winterized crude. as we sit now vacuum is at 480, mantle temp is 85 and head temp is 22. im thinking vacuum is much better today as we got well below 100 micron dry. stay tuned, all advice is welcome.

If you can Place vac pump on the table to shorten the line all seems good👍

Change any thing after the run

so we are sitting at 390 vacuum, 183 mantle and 114 head temp. Things are stating to thicken up. I think we are close. any input?

Nah not yet mantel 240 heads 230

The picture of the whole setup really helps to nail down your issues.

minimize the length of the vacuum hose. Probably best for you to put the vacuum right beside the cold trap, and to have the hose go straight to the trap, with only a little extra length so it isn’t too tight. Same thing with the hose from the cold trap to the triple cow. No more than a foot should be needed there. Make sure all gl connections (the blue screw on caps) are tight, and by this I mean the hose clamp clamping the hose around the connection. Just double check them.

It looks like you have connections for both thermometers that require you to make a nice seal. You should have small o rings that fit inbetween the black caps and the glassware, but I would put a layer or two plumbers tape onto the glass threads before screwing the cap and thermometer into place. These are your 2 most likely leak places on your system. Once they are taped up, twist the cap on nice and tight and you should be good.

Vacuum grease? I only briefly looked at this thread, but make sure you have all glass to glass joints lubed up with vacuum grease. Take a small amount and apply it to the top 1/3rd (thickest part) of the male piece, and then slide it into the female and twist the glassware back and forth. This should create a nice thin clear layer, and keep things from leaking. Make sure you are using dow corning high vacuum grease, or the apeizon stuff that is more expensive. As long as it says its for high vacuum you should be okay.

I would bet a lot of your issues stem from your cold trap. you NEED to be using dry ice in either isopropyl alcohol, ethanol, or acetone to be able to reach cold enough temperatures. These temps are required to condense the garbage that gets past the main condenser. If the cold trap warms up, some of the things it has condensed may evaporate, or drip down into the collection flask below. That flask should also be on a dry ice slurry. If these volatile compounds warm up, they will most definitely weaken your vacuum, and cause your distillation to suffer. Keep that cold trap coldddddd. Also put less alcohol into it, then fill it to the top with dry ice, then slowly pour more alcohol into till it is all chilled and filled to near the top.

Feel free to DM me for more help

Thanks for the input… We have iso and dry ice in the cold trap with a polyscience immersion chiller. Should we take the immersion part out? And the thermo tip i think will help a lot.

Much appreciated…

Yea, I would just use the dry ice and iso directly in the condenser as it is pictured. You can watch the dry ice and as it sublimates away, just add a bit more. It sounds like the way the chiller is set up now just isn’t cooling enough.

Put cold trap RF submerged in di also.

You can try a mist filter but it wont completely eliminate it. It probably isn’t the best stuff to inhale so route the exhaust hose to a vent hood or outside.

Do you have a way to isolate the pump? Are you letting it warm up to operating temp? Use a valve or something similar so you can control vacuum and isolate the pump when you need to.

Get some balloons or a tank of helium to hunt down leaks:

is there a thread on terminology and or a glossary where i can learn wtf a gas ballast is? haha and how do i open it?

A gas ballast is a valve on your vacuum pump ( rotary vane type)

It s used to off gas the volitiles your pump has been sucking in

To speed up the process of getting it out of the pump for else it will stay in the vacuum oil diluting it and effecting the vacuum depth or worse it s lubricating effect on the rotor spinning in the lubricating oil to pull vacuum

What kind of pump do you have?

Not really.

However, Search results for 'gas ballast' - Future4200 should get you that definition

You might even try Search results for 'Glossary' - Future4200

Edit: take away from first search: Small used OLD lol cheap vacuum oven - #27 by cyclopath