I’ve since decided without the ability to apply vacuum the countertop distiller simply isn’t capable of producing as high a quality of product as can be produced under vacuum. Add to that the lack of agitation and ultimately the countertop distiller is simply not well suited for recovering solvent from such a viscous, temperature sensitive compound. With those factors in mind, better control over the heating element doesn’t seem like the solution. Keeping it around to reproof alcohol seems useful, but definitely not for recovery.

I bought a Megahome version years ago and used it to redistill 70% iso to a much higher proof to use for cleaning purposes since I could find the 70% on sale much cheaper than the 90%. I would put several gallons into a 5 gal bucket to let things soak and dissolve residue and when it got dirty and then I would redistill the dirty into fresh cleaning iso. I would stop the distillation before it was finished and throw out the last bits which was mostly water with a little iso and dirt/muck and have a brand new bucket of cleaning solution.

Now I use ethyl for a lot of my cleaning but keep different buckets for different uses. For basic cleaning purposes I distill the same way I used to with the iso, but I use a different bucket to clean distillate from SPD flasks and such to keep that separate for use in winterizing to get it back into the loop.

If I were trying to get a little more anal about it I would use a variac to set the temp to about 180 so it would only vaporize the ethyl and leave the water & other junk alone and then figure out how long it took to do a full run and run it on a timer.

Instead of making a complicated controller just buy the souse vide on amazon or online where ever they go up to 220 degrees and are accurate to .1degree at least the good ones are

I use one for recovering IPA , it’s a uk version but same think , lose a bit though due to vapour loss etc .

I bought one from megahome which they modify for Essential oil and alcohol distillation. Wondering if anyone has ever tried using it to steam distill terpenes. I can’t find any info on how one might use it for steam distilling essential oils.

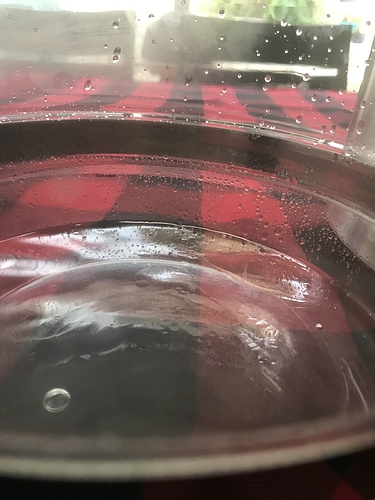

Figured give it a try. Packed it with some

Hemp and filled it with water. Some oil on the surface of the hydrosol that is coming out.

@Fullsailfarm you packed alcohol distiller?

I was thinking about taking the brush off my commercial steam cleaner and trying to run steam through a pvc pipe like I used to with butane…

I’ve used one for my old, funky beer made years ago. Reclaimed the alcohol-- 85% (170 proof) to use for my tinctures. Much better tasting than Everclear. Also, making use of otherwise undrinkable beer. Today I’m reclaiming alcohol from 18 bottles of old white wine. It will be interesting to see how the flavor varies. I did use my Megahome distiller for making RSO but found it was too large and wasted a lot on the surfaces

did you notice your PVC being damaged by the butane?

you’ll notice with steam…

PVC? Please elaborate. I’m still pretty ignorant!

PVC is not appropriate for hydrocarbons. you may not have noticed the issue, but you were definitely dissolving it.

https://www.google.com/search?q=pvc+butane+chemical+compatibility

nor will it work for steam, as it will soften in boiling water…

(rated for 140F…not 120C)

This a bit late in response, just found this thread. Yes the unit runs at the full 750 watts and the dial allows you to set a temperature for shutdown. its the alcohol as an azeotrope that makes this work. The boiling point will be held down as long as there’s boiling action. 100% Ethanol boils off at 78c (173f) but at around 82-85c when at lower ABV. So set the dial at 85c and when it shuts down, you have your 80-90% volume of alcohol out of the mash. Its not worth the trouble to capture the rest through additional distillation cycles IMHO. Now, the worst part is, there is a 40% loss of alcohol to vapors. Check out my paper I just finished and posted here (some then pointed me to your thread…). You can add an external ‘condenser’ inline to cool the vapors enough to recondense almost 100% of the vapors. The flip side is, you’re gassing your house with 40% of the alcohol using the standard water distiller, something to think about. Run these outdoors to be safe.

And a big “Hell No” to using a water distiller for shine. Its like riding a miniature tricycle when you need to ride a bike. You’re going to do a hellava lot more work distilling one gallon at a time. And without an external concentrator, you’ll loose 40% ABV right off the top. The thumper acts a little like a condenser, but doesn’t take away enough BTUs to cool the vapors enough for condensation. Again, lotsa work for micro results when you could spend the same dollars and get a 5 gallon pot still on Amazon with a thumper and condenser.

Condenser_Issues-v1-01.pdf (2.6 MB)

We responded in your other thread. If you use the correct tool for the job, it works. If you use a screwdriver to remove a nut, it may work, but not as successful as using a wrench/pliers/socket.

Right tool for the right job.

We can modify it to make D8 crude. 540 grams CBD isolate, 540 grams citric acid or pH 2 with Hcl to a gallon of DI H20. 4 hour run time. PROFIT!

(Seriously, please don’t do this)

it is indeed. @SkyHighLer hasn’t been around in about 18months, and his last missives suggested he probably wouldn’t make it back this way.

see: All my stuff, solvents, equipment, tools for free, SoCal - #2 by SPD-408

Hey! Has anyone compared a megahome water distilled to an air still by still spirits? Seems like they both function the same but wasn’t sure if one produced higher ABV by default. Is it necessary to regulate the temperature in order to produce 190 proof?

It’s been quite a few years (8-9) since I’ve used it and totally forgot about it until I came across this conversation. My experience with it was not a happy one. It kept on foaming up and frothing over. It did it enough times to were i kicked it across the room in discussed.

Countertop water distillers run way too hot for ethanol recovery. The ones intended for EtOH intentionally have the heat turned down to 180-200 degrees, as the boiling point of ethanol is 173. That’s a pretty good way to make “swish” or some poor quality liquor.

Also, the power and time involved aren’t typically enough to recoup the cost of the unit unless you get one for free.