If you’re open to sharing, I’d love to see your design as well. re-proofing our ethanol is currently in discussions…

5500W ultra low watt density water heater element works great. I’ll see if I can dig up a pic of the still.

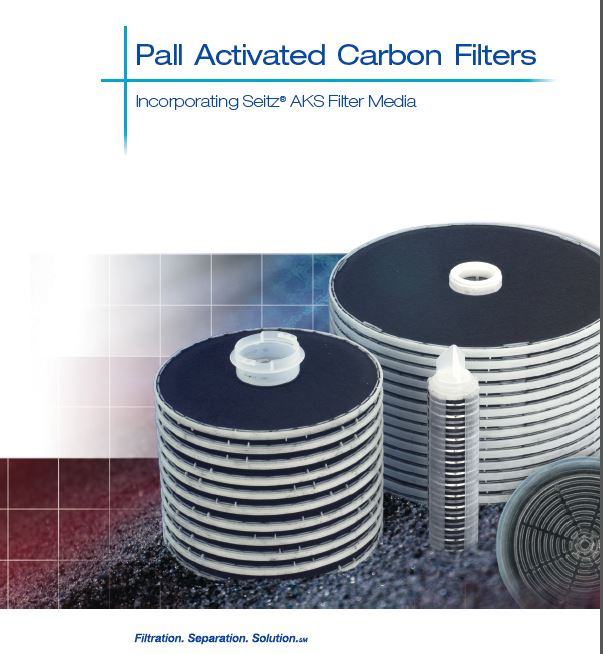

Hi All - I’ve had success using Pall AKS 7 carbon impregnated media.

This eliminates the need for loose carbon and has been effective in removing color.

I work for Pall, if anyone wants info, please let me know.

Jake J. a.k.a. Filter Guy

Does your company manufacture clay impregnated lenticular discs as well? @FilterGuy

Yea for sure! I was just worrying about derailing the thread, but here you go! You can scale that design up quite a bit. I can post a pic of my current setup as well later. I built it years ago in college as a craft still to make vodka, so it’s not exactly how I would have built it today. But it just so happened to come in handy these days for re-proofing ethanol.

https://homedistiller.org/forum/viewtopic.php?f=60&t=36050

@square_root_pharms Right now I just dilute the ethanol to about 40-50% with water and distill over a propane burner. It’s slower than distilling higher proof etoh, but I learned my lesson on why not to distill high proof ethanol over a flame a while back when I had a still fire that could have easily turned into a disaster with an explosion. The way I’d like to heat it would be welding a threaded bung in the side of the keg and installing a heating element. I still wouldn’t recommend that for distilling high-proof etoh, though. A bane-marie setup would be the safest way to heat a boiler charged with anything over 100 proof.

To my knowledge, just the carbon. What does the clay do ?

It’s just another adsorbent mineral used for filtration purposes.

It’s also said to remove water soluble impurities.

Due to the polarity difference of alcohol vs butane there is a possibility that it will not work as well as butane with some of these adsorbents. But you never know until you try.

Butane is a hydrocarbon , ethanol is an alkane

@Photon_noir Any chance you’d be able to break down how the polarity of the solvent affects ad/absorbency?

Ethanol isn’t an alkene, it’s an alcohol, alcohols have hydroxl groups.

I read a paper saying that hydroxyl groups lower the activity of bleaching earths, and I myself haven’t seen any great results trying to scrub ethanol with them. Carbon is very active in ethanol. Alumina and PVPP could certainly use exploration.

I need that ![]()

Use the tank of a boiler used

IT has a massive coil inside heating

A dip tube thermowell

2 aditional valved ports

A botom drain When lucky

Placed on top of a magnet mixer

A stirring device magnet rod is 6" long and 3/4" thick

Weld in 2 Sight glasses and a T on the botom drain pipe for liquid level indication

Gleud in a chromatografie column )

Get Some pics posted by next week

Only mod Thx to You is changing the diameter of the head

Butane is an alkane. Ethanol is alkane alcohol. Naturally, alkanes end with -ane and alcohols end with -ol. Eth-an-ol is ethane with an alcohol (OH) group on the end.

@ExTek90 Not without writing a book. The solvent (and not just its polarity), the solute(s) functionality, and the adsorbent functionality, along with temperature, pressure, and other physical phenomena all interplay with one another to affect the final result.

Are you going to use that still you were building to re-proof your ethanol as well? Head diameter won’t matter much in a simple reclaim still. But if you’re going to use it for re-proofing I would recommend doing it in a separate step after reclaim, as proofing it is going to take longer with the added refluxing process and then leave a bunch of water behind in your extract.

You’ll also want a needle or gate valve in your takeoff tube to control the equilibrium within the reflux column if you go with the liquid-managed design. I’m not quite as familiar with the operation of coolant-managed or vapor-managed designs, other than between the three designs vapor-managed seems to be the most popular design for speed and efficiency.

Nice Any papers or links to this for i am a dummy When iT gets to the dynamics of stille

Thx

Yea! This is the parent site to the forum I linked to above. Lots of info here for reflux column designs and such.

This is the forum where there are a ton of examples of different builds and good info on running them. Just FYI though, the mods are not cannabis friendly. But there is so much info that can be found with the search bar you really don’t even need to join or participate to get answers to almost any of your questions.

https://homedistiller.org/forum/

I’ll have to start a new thread on this topic very soon (maybe tonight) as I hadn’t realized how many people were looking for this information on re-proofing their own ethanol. I’ll try to compile a list of more specific links as well.

As for ETOH color remediation, holy hell I can’t believe it took me 3 weeks to check out that thread on BHO color remediation. One thing that came to mind when thinking about how those filtration columns would work for ethanol extractions is how differently the carrying solvent would interact with the filtration media given ethanol is much more polar than butane.

I wonder if purging the ethanol and diluting the extract in heptane or pentane would interact with the filtration media in a similar fashion as butane?