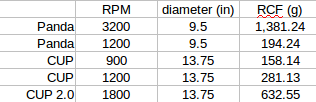

Panda is 9.5 inches in diameter. I have it, didn’t check, thought i had 1200 rpm version. So that was a fun thing to find out.

So Panda comes in 3200 or 1200rpm?

and now CUP comes in 1200 or 1800.

- Must have misread when i bought it, says 3200 on the back.

Almost seems like having a few Pandas with fitted bags is the way to go to minimize solvent loss. May have to buya few more and give it a test.

if you can get it past the regulators in your jurisdiction, or don’t care what the man has to say ![]() it sounds like a decent plan.

it sounds like a decent plan.

Certainly waaay cheaper while you’re in “wild west” mode…

Im curious as to why there aren’t compliant centrifuges in bulk. There is certainly a demand for it. The one you linked previously is $30k, which seems steep for something so simple.

at $15k used I didn’t even bother asking those guys how much they wanted.

without class 1 div 2 it wasn’t a realistic option here. our city permitting troll is a royal pain.

Do you have any knowledge on approval for certified labs? Im tempted to design a centrifuge and get it approved. Could be something this industry is lacking.

They exist for 20k. Pinnacle has one. If you can get it done for cheaper, do it.

link or it didn’t happen ![]()

electronics will need to be potted. Motor will need to be sealed and probably DC brushless to get your speed control (although PWM will work).you will need an engineer willing to sign off on it. not sure PSI (folks used by Precision and a couple of others) will work.

Once upon a time I figured I could hack one together for about $10k assuming I did all the fab work. I’d have to get better at tig, and I would have sourced used parts. Would have cost me another $10k for engineer sign-off I reckon.

I guess it didn’t happen then. I was waiting for them to send me that quote, but I’ve only got it over the phone and i can’t find any links on their page.

Oh Bother!

It’s basically a bunch of stacked membrane filters, using pressure instead of vac by pumping the liquid through. Automation can be nice, but can you automate cleaning? Much better than huge buchners, but still a lot of cleaning and maintenance. My experience was with a different sticky product, so maybe spent plant matter and kief is not so bad to just spray off though.

For EtOH soak I just squeeze it out in a mesh bag, call it good enough. Spinning it off sounds really nice, but if you need something air powered, filter press could be the way.

Btw, what size filter did they give you? 30 inch, triple stack lenticular? I’m trying to figure out if a inline 10 inch single stack would be usable instead of a 10 inch ss buchner.

Give is a strong word ![]()

single stack. I imagine it would improve your process flow.

I found adding a 24" snorkle between sight glass and vent gives operator time (2-3 sec?) to avoid throwing cannabionds on the ground every time.

Haha, yeah give was not the right choice of words. Ok, I’m gonna call tcw (who are the suppliers to delta for those filters) and discuss cartridge filters further. The one you bought come with diatomite?

Edit: so what do you mean throwing cannabinoids on the ground? I thought it was closed loop and went straight into a carboy after the filter.

no diatomite.

There is an air vent on the top of the filter. one lets the air out as the unit is filled, and shuts the vent when that is achieved.

or more commonly after that has been achieved ![]()

Knew it would happen when I read the manual, was still caught off guard by the fountain.

Delta adds a sight-glass, and relocates (replicates) the vent above it…but there is still zero response time built in. Lowering the motive pressure helps, but I found a 24" x 1.5" spool gives a nice delay and has the bonus of bringing the pressure gauge up where I can see it.

What I’d really like is for it to whistle like the fuel tank on my bus does. The whistle is on a dip-tube. When the diptube is below the surface, it stops whistling…

Edit: eg :Whistler® Fill Signal - Scully Signal

Ok, thanks a lot for that info. ![]()

Everything seems to change between the times i get updated info about anything in this industry. I wonder why they aren’t using diatomite anymore.

Major advantage of something like the CUP is it’s certified etc etc. Lots of different ways to do ethanol on a budget, but building things to fire code and custom technical reports is such a pain in the ass. It’s worth the money for an out of the box solution.

Anyone here ever run one of the Ethos systems from Capna Fabrications?