.

What water is being produced in decarboxylation? C22H30O4 → C21H30O2 would only be the removal of 1 CO2

So since we have agreed that decarboxilation is a heat reaction.who is willing to fill their miner

Bucle her up in high pressure clamps

Put in Some oil of Wich terpene content is known decarboxilate with heat and presssure say 25 bar

And test the terpene content afterwards

I would think that 6 hours at 90c gets the same decaboxilation % as 1.5 hours at 135C

And If course same oil at ambient conditions decarboxilated and a report on that

Compare what advantage decarboxilation under pressure has

I believe that live resin decarboxilated like this might make Some mighty fine vape carts😀

Interesting I have some mighty fine. Full spectrum I would love to decarboxylate Under Pressure to preserve terpenes I could probably Cobble together a closed loop base 10 x 10 or 12 by 10 spool but I would only be able to get to about 150 to 180 PSI not 25 bar LOL then again I don’t have a GC yet so I wouldn’t be able to get Analytics on it

This was posted on another forum from a member named “fft” with only two posts total:

I totally agree with your comment on doing some testing in real life conditions. With HPLC pricing coming down, I’m hoping one of the labs will so some practical testing around time / temp for everyday applications like cannabutter.

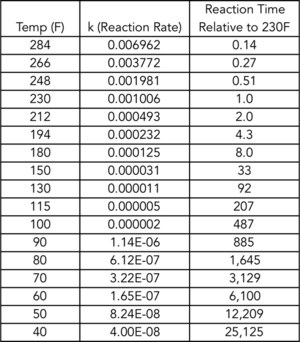

In the meantime, your other comment motivated me to do some calculations using a paper I read recently on the reaction rate of THC decarboxylation. The reaction rate follows a first-order rate law, so by plugging in numbers I was able to calculate the reaction rate at a range of temperatures:

Sorry for the huge table. Anyway, at different temperatures I calculated the reaction rate (middle column). In the right column I compared the rates to get a relative sense of how much more time was needed to get the same results as a decarb at 230F. For example, at 212F it takes 2x longer to convert the same amount of THCA to THC as it does at 230F.

What this suggests is that while, yes, decarbing happens naturally at room temperature the rate is quite slow. At room temperature of 70F, it takes ~3000x longer to decarb as it does at 230F. This jibes at a high level with some other research that looked at how quickly the components of hash and hash extract converted/degraded at normal storage temps.

At the 115F dehydrator temperature, it takes 207x more time to get the same results as it does at 230F. Now, if I usually decarb in the 230F oven for 30 minutes, that doesnt mean it should take 207 x 30 minutes at 115F, because a good portion of that original 30 minutes is used to heat the weed to temperature. But best case it would probably take a few days in the dehydrator to get a decent decarb.

Man i am sorry to say No in house analitics over here

But i remember back in the days When making RSO in a Rice steamer

First the solvent gets out

Then the water

And then You Could see decarboxilation by the size of bubbles and way iT “cooked”

But the Rice coocker would not pass 100C

So had to keep pressing the cook button ![]() Eventually the decarboxilation seized

Eventually the decarboxilation seized

Don t remember the time frame

But My lab report came back with verylittle thca so sure iT s possible

And iT didn t seem like days

Tread that has Some interesting similaryties

Exactly!

But we need to pull vac and add some N2 too

Yep

I would prepare pressure chamber

With a vent valve set at maximum pressure allowed for that chamber

Pull vacuum bring to permitted pressure

With N2

Bring on the heat for the time that seems fit at the temperature that seems fit

Should not be to hard setting up this sort of rig

![]() So who is gooing to write history on this one

So who is gooing to write history on this one ![]()

How would the pressure shift in the headspace as heat is added and co2 generated? I imagine a small prv set to just under the max your decarb vessel is rated for would be a must for this process just in case?

Sorry the vent valve = pressure release valve😀Damn forigners

Yes sorry prv is pressure relief valve or PSV pressure safety valve I’m in the oil and gas business so I’m used to calling them that

I would like to second this piece of information. The reaction depends on an input of a particular amount of energy per mole of material to be decarbed. The vacuum removes CO2, but would not really accelerate the reaction in any practical sense, nor would it change the activation energy required for the reaction.

But iT avoids o2 contact !

Did you ever find it? ty.

Only the bottom right was done in a closed reactor, but you can see the difference it made. The sum CBD content decreased by about half after 120 minutes. And just the CBD content also decreased which was not seen in the other trials. This paper was just decarbing the oil on like a glass plate or something if I remember. @Bonevader

Hi BR, could you share the link of this test??

Thanks

Citti, C.; Pacchetti, B.; Vandelli, M. A.; Forni, F.; Cannazza, G.; Analysis of cannabinoids in commercial hemp seed oil and decarboxylation kinetics studies of cannabidiolic acid, J. Pharm. and Biomedical Analysis, 2018, Vol 149. Pg 532-540

Thanks, ![]()

Hey guys, newbie here just trying to understand a little bit more about the decarb process.

Our end goal is distillate and we would like to put our crude into the SPD and be able to short path without fighting the boilover for the first day lol.

So if I’m understanding this right, vacuum doesn’t effect the decarb other than lowering bp and preventing oxidation? Being that it’s the thermal reaction that actually achieves our decarb, what does this mean when we’re under vacuum? If we’re at 135C for 1-2 hours open atmosphere, under vac we could do what, 110C for 6 hours?

Forgive my ignorance I’m hoping this will help me grasp the concept better and maybe some other lurkers as well.

Sounds like you have a thorough understanding of the relationships at play. Decarb will likely occur in oil as low at 90C regardless of pressure, anything higher than that and you’ll be fully decarbed. Being that you want to remove volatiles to get your SPD going, heating at a little higher temperature under the hardest vacuum you can achieve will definitely help. Ideally you can stir while doing this. 110C for 6 hours should be plenty IMO, if you can pull a vacuum of say -20 inHg. Good luck!