If they’re not actively assisting in reducing the flammable gas concentration then yes

Check out “nomex IIIa coverall” compare to “carbon x” and “drifire” these all seem acceptable some are blended with kevlar and static dissapative fabrics. These have very high arc ratings and there are some impressive videos online of workers putting these suits to test as seen during some serious industrial/electrical accidents.

Some colleges started using the basic nomex IIIa fabric with a chemical splash protection called Nomex FR/CP Lab coat or coverall style. Some started doing this after a young woman lost her life working with a pyrophoric organomettalic catalyst at UCLA she was not wearing fire retardant clothing-RIP…These are made by dupont and some partners you can find at bulwark.com-currently out of stock in my size so I went with “national safety apparel” @ www.thinknsa.com who refered me to Austin owner of firebrand safety. Austin helped me organize my order between National Safety Apparels inventory and I even got some static dissapative boots with his partner at redwing boots. He put my order together quickly and ensured us everything was in stock and ready to ship. I liked the nomex FR/CP lab coat/coverall for a basic lab protection. We chose to go with more fire/arc protection instead and opted for the category 2 level of protection since the nomex fr/cp is only level 1. I did this because I liked the carbon x materials performance during various burn tests compared to nomex IIIa. Carbon x seems to have just a little more resistance for each category. National safety apparel has long sleeve shirt and long pants for undergarmet protection made with carbon x/drifire and other inherent fire retardant suppliers…Very impressive for how thin the fabric is. Or if you want to move fast and be light shop, “walero nomex underwear” developed with nasa & used by formula 1 race car drivers. Very light weight with outstanding fire protection just a little pricey. At least you’ll be dressed to go fast. You can find the race undies @ places like, “competitionmotorsport.com”

You can reach austin @

Phone - 316-641-0349

Email:

asharp@firebrandsafety.com

Make sure you & your employees are protected and do not charge them or make them pay for this clothing. Do not wear polyester while working with solvents. Cotton seems to be the accepted undergarment if you just choose an outer coverall or lab coat type of protection.

Don’t trust bhogart with your safety ![]()

can static hit if you are standing in snow? I know its static in my house because the vac cleaner hose is covered.

Sure it can. Standing in snow doesn’t necessarily mean you are grounded. So if you have a charge on you - and the humidity is such that an arc is possible - and you come into contact with something else that is either sufficiently charged in the opposite direction or you are very charged and you come into something that is not charged then you can get an arc.

I try to think of static charge like normal electricity - if you could exchange a charge across something, then you can exchange a static charge too. You know?

Similar rules apply to higher voltage arcs, regarding humidity, distance, things to do to protect yourself, etc. Only instead of a tiny spark that might be an ignition source… you’re hit with an arc with a constant flow, protected only by your PPE, good practice, and hopefully a circuit breaker somewhere before your ass is roasted.

If you really want to know more about it…there’s an awesome book in the Library of Congress. ![]() Its all about how to make the charge, dissipate the charge, technology that uses the charge, technology that is hindered by the charge. Devices from the old days (1600s) - devices from the new age (1900s).

Its all about how to make the charge, dissipate the charge, technology that uses the charge, technology that is hindered by the charge. Devices from the old days (1600s) - devices from the new age (1900s).

Question for anyone inclined would a 14g extension cord connected to a Unistrut rack be sufficient for a reliable ground? Is the wire size even going to matter its only for static I am assuming it wont matter? My house main steel conduit is exposed where it comes in was thinking would be a good point of connection and would have no power just a ground.

Damn. I’m glad you said this. Was about to outfit the entire crew with jumpsuits

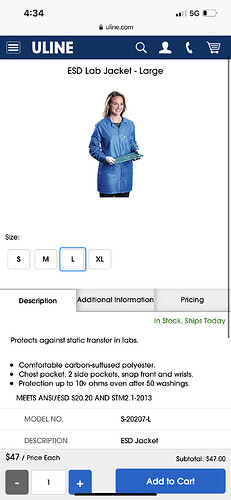

Google some lab coats. Most come with chemical resistant/fire resistant/static proof properties etc.

Good ol Uline

So… after agressive inspection and disassembly of our unit to play Sherlock Holmes and figure this out… I quickly came to the realization of my problems were drierite sediment and “rocks” for that matter getting lodged into the sauce server gun.

Who what how where when and why you are all asking… welp… this is my explainatiom of my theory as to the situation at hand…

I don’t think @cyclopath will mind me copying and pasting our conversation from text so I don’t have to repeat and retype my entire analysis.

“Upon disassembly of the gun and hose… I found drierite rocks, or rather “pebbles” lodged in gun…

I wonder if this has anything to do with this static issue…

As ironic and contradictive as this may sound…

After what I just found…

I heir on the side that due to this specific circumstance with an obstruction in spray gun such as drierite lodged in valve mechanism could have very well been the culprit of our issue…

My theory off the top of my head…

Drierite lodged in valve created a blockage that further created restriction in flow, and an increase in pressure therefore resulting in more intense friction and static charge out of the nozzle of gun…

Makes sense to me

Just my line of thinking…

I think it has relevance. I think this is correlated.

Where would that have come from?

What pressure were you pouring?!?

We have mol sieve column directly above our collection.

Intense Pressure forcing beads back and fourth obviously dislodging some pieces past filter screen… or puncturing screen for that matter…

(20um mesh-like screens from BHOgart)

Dropping in oleoresin below…

Resulting in a blockage in hose and furthermore the spray gun… indefinitely creating more friction which to bring it a step closer… ends up in more static charge…

We use about 15-20 psi give or take for pouring “sorbet” as we coined it.

When we pour for sugar, we like to keep it warm to allow for a less- viscous transfer of resin from collection to parchment or Pyrex.

Residual pressure created from minimal left over solvent helps propel oil out of pot once heated

We pull damn near almost 97% of our solvent out

(97% that is, at least from our calculations and data.)

Warmed up oleo resin with 15-20psi behind it Helps with smooth pour out

When we leave solvent in for when we produce glass we don’t need more than 3-5 once collection jacket is cooled down to 40-50F (5-10C)

When we pull all our solvent out for consistency specifics we use the aid of head to keep it “honey like”

Extra pressure created by residuals left that are seemingly “trapped,” if you will help build that 15-20 psi we like to have

so, after struggling to pour out for 10 min or so. we turned up heat by a pinch… literally 5 deg. F to bring up to 20 and barely anything more happened…if anything at all.

Shortly after, Started to see some odd and unusual characteristics with oil coming out of gun…

One of the other operators said the “alien like”characteristics of the oil was a pure sign on static charge building… he had this happen to him once before, few shifts back and gracefully no ignition took place.

But on that night… it happened

bam… tray caught aflame.

Literally happened “AS” we were talking about it and speaking our observations aloud.

I was watching the first time. And attempted myself the 2nd time. I was standing away to ensure this aspect Youre speaking of did not take place

That is the touching of steel nozzle to aluminum trays…

This is the mind boggling aspect…

We have been doing this the same way for almost a year… no problems.

Have had the gun for 8mo

Bottom spout pour outs as per post “sauce server days”

Nothing. No problems.

Oddly enough we recently started to use drierite in replacement of our clay beads…

We thought this would help a moisture issue we were dealing with back when. Issue subsided and we continued to use drierite.

clay beads are round and not jagged.

Drierite is jagged and non uniform.

We use BGOgart style micron screens as mentioned above…

Something I think with enough pressure and the right pin point can be punctured. Therefore falling down into collection and further making their way thru hose into gun.

After finding that blockage in gun I’m paying detective and the pieces of the puzzle are making sense… seemingly…

I wish I could show you all.

It was unusual and unreal. Well real, nonetheless but fucking insane.

As far as “what it looked like.”

It was Not like a seemless stream of resin discharging from nozzle…

It wanted to clog and crawl back up the nozzle of gun… taking form (shape) of something I can only describe as “alien like”…

After @WhereAreTheStones there a pic out of static latent hair lie after running a ballon on head and hair begins to stick up.

Operator who said this. Claimed he had been experiencing “shocks” to leg from touching cart we use to pour on…

Also claimed that he saw a literally spark from nozzle of spray gun to tray and immediately stopped pouring… witnessed the same thing happen to me that happened to him…

(After my analysis it dawned upon me this began to happen shortly after we implemented drierite.

Although not immediately after implementing such product.)

…Which was the unusual build up and “crawling” characteristics taking place before our very eyes… and then once enough charge built up… (so we theorize)

…”static”…

Took about maybe 5-10 seconds of watching this “alien like” ball form and then ignite.

Dude. It was fucking insane…

I really wish I could have visually documented that happening… it was the most buzzare shit I’ve ever fucking seen in this industry.

As we were both talking about it and agreeing to what was taking place in about a 5-10 second time frame… poof.

Come to find out after a serious pause in production, I dissasembled system, part to part. Fitting to fitting. You name it. The whole nine yards. I came to observe our very gun we use to Harvest oil was clogged with drierite rocks… (explained at top of post.)

Have yet to put hose and gun back on and reattempt to pour out.

No o don’t have lead from such event as to why I haven’t done so, just busy. Digressed back to what I know works. Bottom spout pour.

Hope this helps and gives insight.

Lesson learned to take gun apart and clean religiously… as with anything…

Crazy…glad everyone is safe! Thanks for sharing your experience.

Team is good. We acted as one. As far as not having any structure around procol for these types of events we all took positions to swiftly act in a rather speedy and professional manner. Issue was handled in less than 60 sec. very proud of my team and how we were able to act as one and manage such a terrific situation.

Will be continuing to take preliminary precautions and implement strategies to reduce the risk of these situations. Adequate PPE, initiation of proper grounding to all steel, pumps, all of it… humidity control, upgrading ventilation, static dissipative apoxy, I mean all of it… if anyone has anything they like to use in their work zone throw me (and the rest of us) a bone to chew on.

Much love and appreciation.

Didn’t read the tread so someone might have said it already, if you can bring your humidity up in the room

Wasn’t the sure cause of humidity I don’t think But yeah. We did that

then you might have missed some life-saving information…

you’re looking at a report of IGNITION during pour out. if you don’t do that, or play with hydrocarbons, then it’s obviously no skin off your nose. still seems like a bad precedent.

“nah, I didn’t read…but this might help”

WTF are you talking about… I dont need advice on this topic… OP says “Requesting help from all sources on how to counter this issue.”

You know as well as i do that bringing up the RH if too low can help reduce static electricity, CLEARLY its not going to solve all problems but its a small buffer…

And why do you feel the need to put your two cents in on my comment, is there a post limit in this thread… I’m not wrong in my original post, so what are you trying to get at other then putting a bad taste in my mouth for you now…

OP should probably have given more details in their original post, but did not.

You’re absolutely correct that

a) RH is a place to start with static

b) if you don’t do pour-outs it’s no skin off your face if you’re not aware that one way things can go south is that debris in your pour spout might in-fact cause enough charge separation to ignite the pour.

Really happy I work with someone who’s response was to have a pull down fire blanket there two days later…

Also appreciate your honesty. Both in “I did not read”, and “that pissed me off”.

Not dissing you, or your advice.

Let’s just say I find “I didn’t read” triggering.

Especially around sources of ignition.

Does that work?

It rubs the lotion on its skin

some wook lit the pour again

Deleted