same thing as youre thinking. It can be used on the ass end with a pump too to help cool the gas down as it enters the storage bottle. I may have a pump for sale if you need a trs pump spark free rated. I used salty water- be careful it ruined my coil and hoses. Im an oddball but i never trusted the stainless tanks with triclamp for storing. I store in a propane tank.

Thanks men thats sound like a great option for me i could used my chiller on my material colum Then use the pump.to.move my solvant.

Send me info about your pump.

But im located in southern mexico.

Solvent tanks shouldn’t use lc02, that would be on them for doing it incorrectly. If all of the prv are blowing C02 everywhere, they are also doing something incredibly wrong. The steel has to be rated to withstand those types of pressures.

Overall, the equipment is being operated incorrectly and you, or/and them, need serious training to use it properly. Everything you’ve described, is the exact opposite of how that system works.

These guys were trained by the owner of the company who was trained by someone from the manufacturer (bizzybee). I don’t know why they wouldn’t tell them to not use lc02 on the solvent tank, but maybe they did and nobody was paying attention. The PRVs weren’t blowing constantly, but they would blow often and when they do it is a big problem. I’m certain they were using too much lc02 since it was happening a couple times a minute and would keep running it until recovery, but any system that even occasionally blows off CO2 with a PRV is not safe since you don’t know when a PRV will release pressure. I also think lc02 is too cold and causes the surfaces of the equipment to reach dangerous temperatures. Why don’t you show me a video of how lc02 is supposed to work, because the only time I’ve seen it in use it was a mess like this? Despite the problems with the lc02 system, they did know how to operate the equipment, and they were able to make a lot of very nice extracts from that machine using low quality material.

Putting everything in a 400 psi refregeration tank. Psi was pretty fuckinh high in the morning from leaving it outside.i dont want to try in a hot mexican day.

Make sure you leave 20% headspace to keep those pressures a bit lower.

Thanks for the advice i only have about 8 lbs in a 30 lbs tank.

Im.actually looking for a good source of tane. Its pretty hard here in mexico. Only canned tane but my whip it distributor just closed shop.

Not to sure if i trust to other brand i can find around.

Im.looking for bigger tank.

I have a big season coming. Rainy season is done here in the montain so best material of the years will be coming out in the next 4 month( we harvest all years long ) and will be precessing a lot of fresh and dry material.

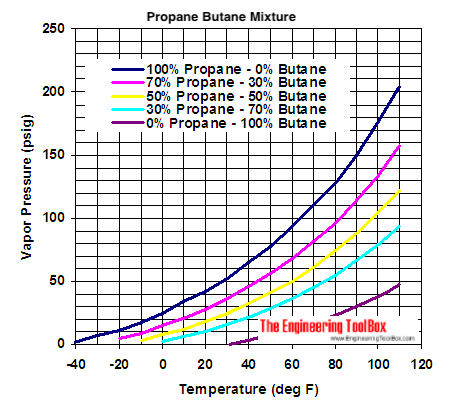

The advice to remain below 80% liquid fill is solid, however…the pressure will be the same with 1% liquid fill or 98% liquid fill. It’s set by the composition (butane/propane/isobutane ratio) and the temp.

Propane Butane Mixture - Evaporation Pressure

high pressure either means high temp, or high propane.

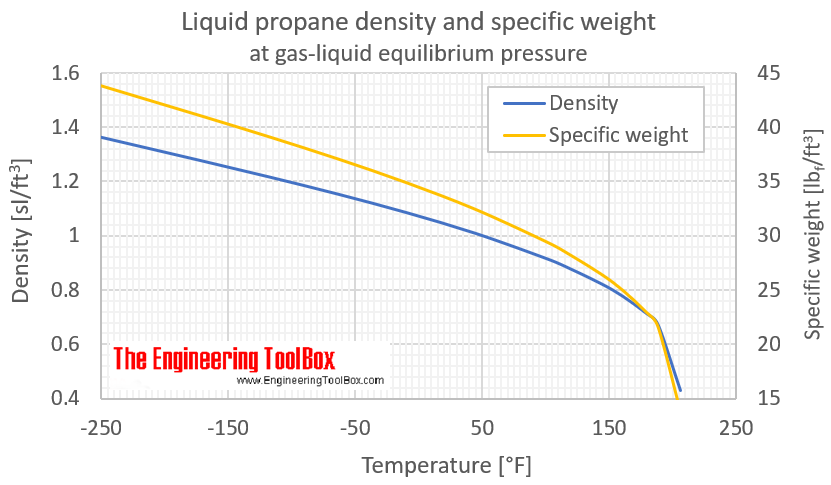

The liquid will also expand with temp.

Once you’ve reached 100% liquid fill, then pressures go up….and unlike gasses, most liquids don’t compress, and so the tank goes…