I would’ve thought get one that’s rated to the max psi of your gauge.

I love these but cant find knock off anymore

I just picked up some used RL4S8’s on ebay, looks like a few 1/4" RL3’s on there at the moment.

r they ones w ptfe seals and no oil

I picked up units with viton seals, theres a listing on ebay for the 1/4" also with viton for a cool $99. There is a lubricant, im not sure you can order it without.

u def can order w no lubes

@Soxhlet I bet knows the part number by heart aka the leader badge

I see the -SC11 Special Cleaning and Packaging option, I guess its by special request cause the catalog just says they use a different lube but offer other options upon request. Im not to concerned as Im putting mine where they wont be in contact with liquid or product. Not ideal but how Im starting off.

they make cheap brass ones that will get u buy @Killa12345 a link?

but no liquid!

I have ss ones like the cheap set ones but I csnt find right now and I have the old adjustable ones oss use to offer

I’m needing a new one bc I’m rack mounting my system, getting to heavy w dewax material and crc . maybe it’s just me and top heavy

yeah I wasted $800 on rack and parts needed to rack mount it but that’s everything bc I had the rack built for 1/3rd price

Hi,

what size and config?

As mentioned above you’ll want to base the PRVs pressure release on your lowest rated part. You should go with the 125 psi as you shouldn’t ever get above around 90 when using nitrogen assistance. The reason we use these is in case your nitrogen regulator fails and exceeds it’s set output pressure.

Anyone have an idea of why this would be happening? This is happening near the pressure relief on the rail that connects the bottom of each material column to the crc before it heads to collection. Too high of psi on nitrogen assist? Its just bubbling up a little bit right there on the past few runs.

What’s the oil coming out of there? A tee? That’s not the prv right? It’s to the right in the photo?

Correct. It’s the nut on the T, its a hollow nut. Never had it happen before and it’s just putting out a little glob every run. Not even sure how its happening. Definitely going to have to rip it apart and find out.

Hey guys,

I just want to say a couple of things regarding the PRV/PSV:

- When you say what PRV should you put on your system, you are referring to rating of the PRV or discharge pressure? Rating should be as the vessel it is protecting. Discharge pressure should be according to API 520 - part 1

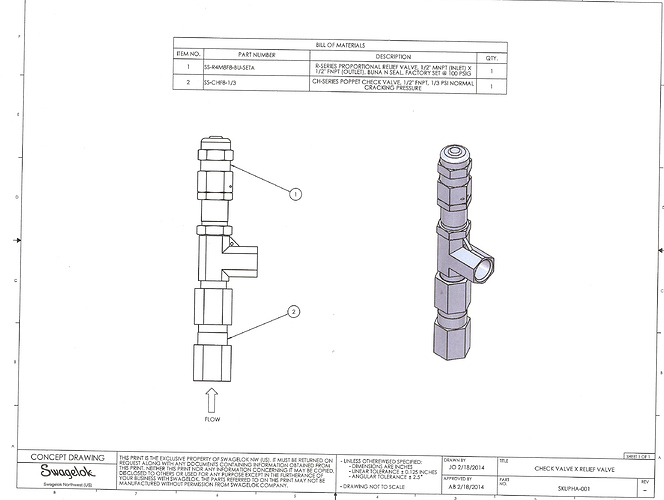

- Placing a check valve at the inlet of PRV: You shouldn’t place a check valve as the inlet of the PRV should be unobstructed. You can place a full bore valve (full bore ball valve, f.ex) for ease of maintenance and calibration. If your PRV is properly maintained, you wont have leaks either on pressure side or backpressure side.

- You should calibrate your PRV/PSV at a regular interval to be sure that they are functional. For calibration you should ask for discharge pressure calibration, leak test and 90% discharge pressure and backpressure test at the pressure defined by PRV manufacturer.

You should comply with ASME/API standards regarding pressure vessels, anyway.

Hope it helps.

Cheers everybody

Hope it