Does anybody have an explanation for the phenomenon, that at a certain point the pathway D9 → D8 is faster, than CBD → D9?

Is this the pure nature of CBD isomerization via acids, or does something change within the paramaters (e.g. pH) at the end of the RXN for this to happen?

I started one trial with pTSA just for curiosity. RXN temperature was -10°C and the reaction time was 340 hours! 14 days! The process was still the same. CBD → D9 and way before all CBD gets converted, at a specific point, D8 starts to appear. At this point, D9 gets reduced faster into D8 than CBD gets converted into D9. At first I thought you are able to reduce the path to D8 by reducing the temperature (based on the idea of thermodynamic and kinetic product), but it was nearly exactly the same like at higher temps, just extremely slow. Even adjusting the amount of pTSA to a maximum of 30% just had an influence on rxn speed. Nothing really changed.

It looks like the “sweet spot” of highest D9 is determined by the type of catalyst. At least I was not able to significantly change this spot by adjusting pH, temperature, water content, time or amount of catalyst.

Only thing that I still have in mind is to change the solvent. I did every run with toluene. Maybe switching the solvent will influence the stereoselectivity. Comparing the results of hexane, heptane, DCM and toluene may be an idea. This is what this paper has done, but they did not focus on the “sweet spot”.

This is basically a trial and error, or am I off the track?

7 Likes

I have already run most of what you propose

And I am confident that some sort of buffer needs to be in the flask

It s a fact that the resin beads used by this company is mixture of anions and cation beads and under wet conditions produces low 90 Thc D9

This is the proof of concept I use in my experiments lately

There neeeds to be a distraction in the flask to stay on the D9 path

If you insist on trying I would recomend a solvent mixture with acetone or THF

You might create a buffer with that

1 Like

It’s just thermodynamics. D9 (less thermodynamically stable) bumping into other things that induce rearrangement to D8 (more thermodynamically stable).

2 Likes

As a proof of this concept I would recomend you try mesic on hexane

And then mesic on a hexane methanol mixture

1 Like

Acetone is not a suitable solvent for use with strong acids due to aldol condensation. I know you don’t know or don’t care, but it’s also very likely for acetone to react with CBD and THC under these conditions, creating possibly harmful byproducts.

6 Likes

Thank you I hoped for a positive (teaching ) answer i appreciate your advise and knowledge sharing for the community

4 Likes

Why not just use triisobutylaluminium

You can get 95%+ d9 very easily

5 Likes

O I am a big fan off triisobutylalumina

And borontriflouride gives decent yields as well on dcm

But the quest is safer reagents with high yields

3 Likes

Okay that means I don’t deal with a “D9 concentration limit”, that is inhibiting the D9 to overcome a specific concentration, its more like that the second bump’s probability to occur is raising parallel with the concentration of D9. Therefore the second “bump” that creates D8 happens more often due to higher concentration of D9, compared to the possibility of the remaining CBD getting its first ass clap to become D9 at the end of the reaction.

And how does a “buffer”, like a second solvent, work in these circumstances? Does it increase the needed energy for the second bump to take place and therefore decreases the speed of the second reaction?

@Kingofthekush420, I want to avoid pyrophoric reagants. As long as I see a way to improve my rxn, I will not touch it. Like rogue said. High yield with safe catalyst is the main goal.

@Roguelab I ordered some THF and will start to play around with it once it arrived

1 Like

Do you no longer like phosphoric for d9? I recall somewhere you noted a >90% on the conversion with phosphoric in heptane if I’m not mistaken

Triisobutylaluminium is safe to use if you know how to use it

The stuff I have won’t even catch fire in open oxygen, it smokes after like 5 minutes of exposure

Only thing that’s really scary is the initial water wash, alot of heat is generated which is why you need a chiller on the jacket

Other then that it’s basically making d8 with a different catalyst

4 Likes

I know ppl were getting 85% with ZnBr2 but they could never scale it past a kilo or so with that yield

My buddy is doing a 50/50 rn with ZnBr2 20 kilos at a time or so

3 Likes

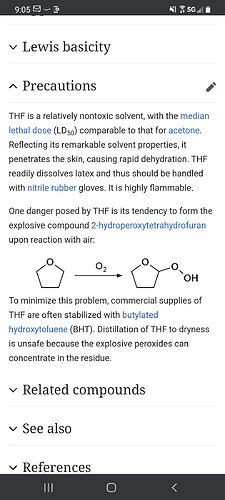

Be careful with THF

I’d be more scared to use THF then triisobutylaluminium

I’ve seen what peroxide can do, they’re super unstable

1 Like

Not sure if you remember my findings of adding mgso4 anhydrous to the flask

With ptsa reactions

I did this to intent higher d9 yields turns out it s no good for that but it does seem to help in getting compliant D8

So adding a compound to the reaction that is not active in the reaction but does guide the reaction in a certain direction is what we need to find

6 Likes

Son we are in the danger trade crap !

So yeah choose your solvent carefully

2 Likes

Phosforic is a bitch

A real bitch out of 3 runs one go s haywire

It s possible Shure thing

But pffff the results are only achievable with drying your own 85% and even then it s a gamble whether it s at that sweet spot

Althou phosforic on Dry ethanol and dried with phosphorus pentoxide In. Anhydrous conditions is also a decent yield of low 80%

But then drying ethanol and loosing it in the wash is a bitch

3 Likes

If anyone can figure this out it’s you two @Roguelab and @roiplek

2 Likes

This would be the safest way for sure

1 Like

Thats what I am also chasing after. But at the moment I am not sure, what properties our second chemical needs to have.

I tried so far ZnCl2. MgO and Al2O3. Just try and error.

- ZnCl2 did nothing, since pTSA is highly reactive at RT and ZnCl2 not.

- With the addition of MgO, a reaction did not take place, even hat boiling point of toluene.

- Al2O3 seems to do nothing.

I reread the MSDS of the beads and in addition on your finding that MgSO4 helped with D8, I came to another idea. Maybe conductivity is an influencing factor?

On my next run I will start to measure the conductivity to see if it changes over time. Just a train of thought

1 Like

You have it exactly.

Which goes to show how little you know about either of them  May i suggest you go read something?

May i suggest you go read something?

you can always do a solvent swap before washing, saves your precious EtOH

How is it a “fact”? Does anybody have any kind of proof for this? It’s just pure speculation on your behalf and decades of research have shown that this claim is bullshit of the most odorous kind. Don’t perpetuate someone else’s lies.

It’s funny how you claimed this can reliably produce “high % D9” and tried selling it for top dollar a year ago while you admit now it’s just a bitch of a reaction that isn’t reliable at all. Makes you look like you don’t know what you’re talking about, and results that others have reported confirm that

Didn’t stop you from acting like you found the holy grail back then when it actually did fuck all. It’s not even a Lewis base like you claimed.

This result could have been predicted with a bit of basic chemistry knowledge since MgO will simply neutralize pTSA and thus render it useless.

Don’t bother, it’s not. You’re not doing electrochemistry here.

1 Like