I used a mulcher connected up to a 55 gall drum and some ice hash bags for a dust catch. it works amazing only problem is the amount of kief that’s being ripped off and clogs the “air filter” but for less than 500 bucks takes about 10-15 mins to fill a drum 2/3

exactly

yes but id get one that has a metal internals, the cheap ones have plastic.

now get something like this to attach to a drum

https://www.amazon.com/BLACK-DECKER-BV-006-Blower-Collection/dp/B00004R9TJ/ref=pd_sim_b2b_1/143-8182560-7478455?_encoding=UTF8&pd_rd_i=B00004R9TJ&pd_rd_r=4c70ccb4-58a6-4dab-91b3-a458951f1178&pd_rd_w=0l9Rr&pd_rd_wg=Yxn74&pf_rd_p=a07701e4-f565-442a-b97f-93ab23cbb7ef&pf_rd_r=VJ6JGSCE42T0B5N1ZS5J&psc=1&refRID=VJ6JGSCE42T0B5N1ZS5J

Are you processing full plants or just the flower?

How wet is the flower?

I see a lot of hammer mill responses but from my experience that is a very aggressive way to size material.

I would recommend a roller mill, creates no heat transfer and is a fast process.

Message me if you want to know more

The $1k roller mill I just tried made mostly pancakes and then jammed (pancake on the back side of the roller) and ate the toothed drive belt in under 3 min.

Might have worked well with frozen material, but I foresee a need to take some action so as not to freeze the drive belt…especially if you choose liqN2 just as the biomass hits the rollers ![]()

Wasn’t my idea, I actually suggested returning it rather than destroying it when it came in the door.

If I’d had LiqN2 in hand you can bet that breaking it would have been more fun. ![]()

Ss Grain Mill - Ss Brewtech NOT the right tool.

got to look inside one of these yesterday (before killing the one above)

https://www.ebay.com/i/392636324596 (edit: don’t bother link is long expired)

it’s an apple masher…

seems to be food grade, and it looks just like a wood chipper inside

you do need to remove a grate on exit port. even to run apples through it.

Can’t see who you were replying to, forum unfortunately likes to dock/remove quotes if you had tried to quote someone else’s post

Personally I use a heavily modified hammer mill, debucked & dried to <12% flower only, and it’s running slow enough to not completely turn the flower to dust or put a lot of heat into it. Bigger problem with hammer mills at the speed most run at is liberating too much cannabinoid-laden dust and reducing size too much, running them at half or less of rated speed is a good way to get around that.

would anyone like to report their experiences simply running material though a screw press [to grind it]? I’ve heard that suggestion from more than one person. I haven’t tried it yet, but have one currently idle, so I’m tempted.

I’m looking for a hammer mill if anyone has a newer used one. Location is Colorado.

thanks.

@BrushBoy how large? Have a 5 hp hosokowa unit with an automatic infeed, located in strasburg. Selling because we needed more throughput and bought a larger 15 hp unit

We have Hammermill’s in stock ready to ship…how many lbs are you trying to process per hour?

They have an article floating out there that has the exact size for best extracting cannabis. It’s not a pseudo one either. They did a control study. I’ll check my bookmarks if i saved when i get back.

Who be “they”? Any chance of a link?!?

I would expect optimal particle size to vary by solvent system.

I would also expect it to vary based on how optimal is defined.

Are we optimizing for $/mg cannabinoid? For extraction efficiency (mg yield/mg available)? Time to process 100kg? Raw extract mass?

When they Had the mm mil size i think is 2. It showed different size and how much was extracted by each size.

I don’t think it research gate but the analysis data report sheets made it seem valid.

How many bushel per hour does it mill? Does it have different size screens?

Has a 3/8" screen currently but if you require other sizes you can buy them from the Hosokawa dealer in NJ

I don’t know how many pounds a bushel is but this unit can do 2-3 lbs/minute

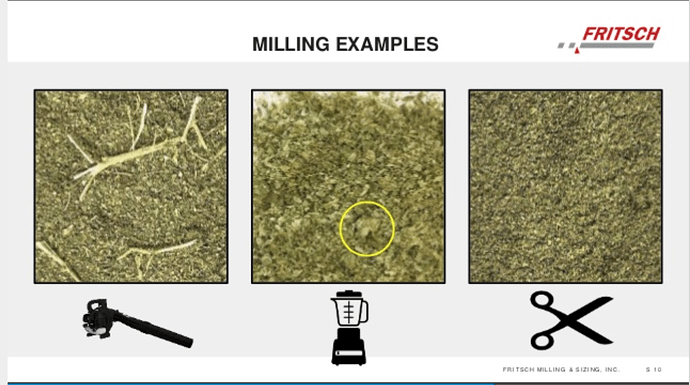

I apologize for the wait. Here is the information I found. Go through the slideshow.

Mill & Grinding particle efficiency

thank you!

this slide seems like it’s worth sharing.

just to get the attention of folks who don’t follow that link you provided.

if nothing else, it reminds me that I might run into trouble if I just hook this thing up to the input of my centrifuge… ![]()

maybe run it through something like the (vacuum based) seed sorter mentioned here Looking for seed sorter options - #2 by cyclopath

THANK YOU SO MUCH!!! I feel like I am speaking spanish to some people when I tell them having consistent particle sizes can give you better and more consistent results. This is one of the hardest things to convince people to try it’s like running a little more weight and having consistent runs is heresy.