I was speaking in metric so were talking about KG sorry for not clarifying

While there are folks hanging around here who can neither metric nor metrc, @Cassin is not one of them.

10,000kg wet => ~ 4500lb dry

Look at it as providing translation for those reading along that don’t metric.

REALLY this is the best our members can answer in 2023 pffff

What happens to the innovation spirit the beeing on the cutting edge of technology from our members !!!

Or everyone is holding their cards close to the chest or folks yust lost the will

Only one lady that’s pushing things forward lately and alas nda have her tied

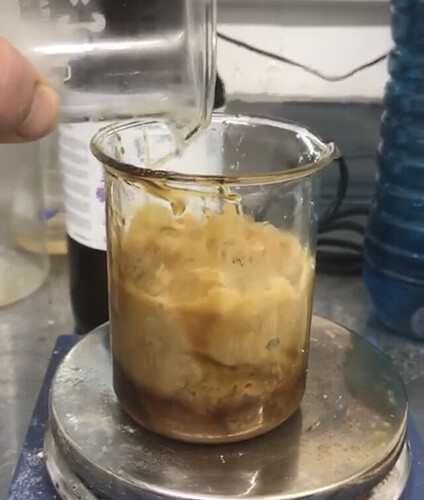

Uploading: IMG_6961.MOV…

@Lincoln20XX you know there are beter ways s

@moronnabis where the hell are you promoting your tech !!

anyway I think a crossover from tree techs

@Kingofthekush420 has it fairly well

Screwpress take the water out and preform @moronnabis his tech on the water fraqtion for complete organic extract

Then hexane extraction on a helderpad screw press maybe residue biomass to a flotweg or pusher fuge

And then extract the cannabinoids of choice

Invest an additional small amount of equipment to cleane your wast water so the reagents cost is breakeven

99% pure accitic cannabinoids by selection at ANY scale in minutes

From warm extracted crude unwinterised arggg

@Roguelab I know that you are aware that we have unfortunately had zero success in our trials of the acidic method you mention, and we’ve spent quite a bit of internal resources on it.

As such, I personally wouldn’t recommend it as a viable commercial route.

For the stated goals of the OP, straight simple water extraction (our procedure is not dissimilar to @moronnabis I believe, though we’ve never plainly discussed details) meets their needs with no dewatering required on the biomass, either screw press or thermal. Single solvent, easy cleanup, very few losses anywhere in the chain.

For thc-a you are right a additional step is needed but for CBD -a it s not I am preforming it on a daily for 2 years now

And dead sure it works

200 kg harvest a day cbd-a > 99%

Ps not trying to sell anything i ll opensource it one of these days

Get some action gooing on again

I recently tried a CBDA trial as well, and had similar results to our THCA ones. I suspect there might be a material difference in our crude for some reason. In a couple of months I’ll have tech on hand that should mitigate that. But until then it’s on she shelf as I’ve got to keep our doors open with commercial production if I’m going to have time to muck about in the lab.

In the context of the discussion at hand, the biggest issue with the acidic tech is that it requires a crude feedstock.

Proper water extraction does not. On a energy input basis (mechanical and thermal) our water extraction spits out CBD isolate well before you can get to acid-rich crude with any other technology at the same scale.

We have a unit that is operational and can be looked at. It was 2000lb per run. This is not the pe120 unit.

Yes water seems great personally I never did it

Reason I called in @moronnabis

Would have called you if I was aware!

But all in all there are beter ways than mentioned previously

We’ve been keeping water pretty close to our chests, NDA’s and all that. But there’s a good size installation running now with all of the correct moving pieces. And it’s rather impressive.

Send me a dm I am in Amsterdam most of the time

Please keep me posted.

Also I think Cryomass Technologies new machine will be a game changer across the entire industry.

Unfortunately, I think NDAs and keeping things close to chest are necessary.

When you say “proper water extraction does not”???

How are you defining crude feed stock?

LOL…I do not understand..what you mean…

Link sent to @minglewithstringile

I’m referring specifically to roguelab’s magic acidic tech, not yours. It requires a solvent extracted and desolved crude concentrate as its feedstock.

It’s cool, but I personally think that their tech is only really interesting for certain niche applications. If you extract wet you don’t need to figure out any of these methods of sidestepping drying.

Rogue…you deserve a “production medal”…a gold star

Rogue is clearly showing you all….water tech is changing the industry. 4200 wake up.

Rogue, two groups…the ones that can not comprehend the water technology…and 2. The ones that know…are few…and do not really want to talk (myself included) because after a number of years of research it all boils down to some very simple technique…3 buckets and a Buchner….

I think the most remarkable thing about your barrels of white cbda…is that it is “white”…perhaps you have a nice salt of some type…or even more remarkable if it is R-COOH.

Can you ship that to USA…?

And of course the problem is that simple =/= easy at scale.

Too many people in group one make that mistake.

Well the “magic acid” may well be more about “ what acid”?

Well the trichomes are sort of half way to “solvent extracted dissolved crude”.

Keep up the good work…excellent.

I would check out Ethos Manufacturing. They have fully automated solutions for Ethanol Extraction that are currently working at scale.

Ethos 5000 System (2).pdf (6.4 MB)

Ship it anywhere you want I have thc.s ND and 0.015 thc yust a recrystelization

Difrance