I buy my solvent from Cannagas and I’ve never once had a problem.

Adam - I wasn’t pointing at you. You never said anything about ppbs I was aiming the comment at THC. I’d have to look hard to find the thread, but I recall the PPB post.

I’m not judging your equipment, I’m writing about everybody’s equipment.

While it’s possible to calculate down to ppb levels, but the result is meaningless. The GC will assign an area count to every peak because that’s what it does. The operator though should realize that the number is not reliable because it’s beyond the reliability of the equipment.

That’s why “<” is used so often. It’s more proper to accurately report a contaminate as “< 5 ppm” than it would be to report it as “0.007 ppm”.

After distilling @SolventDirect so telling people they don’t need to distill your gas is a bad move. We distill everything and this is why. For a clean tank to have this much crap leads me to believe your pig tanks are filthy and never been cleaned. Clean mug does nothing to prevent you from using a dirty ass coffee pot that has never been washed or cleaned.

Thanks for the clarification, Jim. I always enjoy the perspective you bring to the discussion so apologies if that came across snippy–I didn’t notice a reply tag on your post and made a bad assumption. We all good ![]()

Maybe his competitors should do a paid campaign asking for pictures of the reclaim after distilling his gas.

I’m sure it’s just lovely marketing.

Pardon me while I finish eating my coffee.

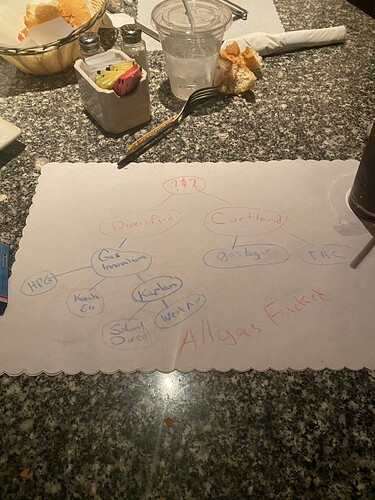

You are correct, BakedAD. Both thcgas and gaslogix are Cortland Energy of El Campo.

Next people will be checking the actual composition of their gases. Some say >99.5% butane (or propane or isobutane), when really they are bellow 98%.

Draw the tree chart ![]()

My girl just looked at me as if I’m crazy as I drew out this tree at dinner. My daughter liked to participate so I feel it was a win.

Diversified has way more distributors than GI but they might be one with the largest market share. Hence why you are seeing the issue be so widespread. I wouldn’t be surprised if they mixed up one of their industrial grade bulk tanks with a instrument grade tank.

We are now noticing some more oddities. We tested mutiple tanks of 100% butane at 80degrees. (Booth temp) if they were all 100% butane they woulda been all close on our gauge at around 25psi. We however saw as much as 5psi lower on some tanks (different suppliers) after noticing a fresh tank of gas was not pushing into our distil pot I had the guys check all the tanks standing pressure. My thought was if this impurity has a higher bp then butane the whole tank should be a lower pressure. Going to be digging deeper into this but we now will test the pressure of eeach tank we intake to weed out ones that are clearly not 100% butane just off vapor pressure. That being said. We had some stuff in 70degree standing at 17psi. Gonna purchase some more sensitive gauges to really dig into this.

This really goes to my point earlier of without these companies individually testing each tank we never really know what is in each.

This is what I use for pressure testing extractors. It’s good to a hundredth of a psi. Mine isn’t the transmitting type. Think I paid $400

What is the net solvent weight you are starting with? Depending on the vendor, some 200lb water weight tanks get filled to different volumes of butane, 70/30, propane, so that might explain the variance in resting pressures.

They all sell it at 120lbs if butane. Should be 112lbs of 70/30 butane heavy and if it’s straight propane you usually get like 100lbs In a tank. These were brand new 100% n butane tanks and their pressure was much lower then it should be at 70deg. Typically butane would have small amounts of propane in it so you would never expect the pressure in the tank to be below the curve for 100% butane. This kinda lines up with our experience where sum runs you can open jars up and the butane doesn’t boil off at all. 0 pressure. If the impurity that is causing all the issues (us and now 10 other extractors in 4 states all having same issues) has got a higher bp then butane it could be what’s making all this happen.

Going forward I’ll log every tank weight coming in (we usually just measure what we distil) and the standing temp/psi. Just waiting for a more accurate digital gauge to arrive.

Having a component with a lower boiling point isn’t going to change the overall pressure generated by this mixture at a given temperature.

The pressure generated will be dependent on the most volatile component of the mixture, provided that component isn’t only present in tiny amounts.

I dont have an explanation for why you’re seeing different pressure readings.

What if in the companies distillation process they have created some different butane isomer that looks the same. I really don’t know just shooting at the hip here. I was always told you can tell your gas %s by its pressure. Are you saying a mix of butane and propane will only have the pressure of the propane? There’s multiple graphs showing otherwise.

So for instance with puretane, if there advertising it ad something its not or can’t be achieved ( i have no idea if it can be) wouldn’t that open them up to a false advertising laws suit. Ive ran plenty of restaurants back in the day that used that in there torches cause someone thought they knew something. Im genuinely curious, it just seems there waiting for the other shoe to drop

Ya I agree I see different pressure from 70/30 than straight propane.