It would have to go down to a .2 um filtration to remove all spores from extract & entail after with a lle to finish it off before roto to remove any other impurities as such. Keep in consideration as well, if a testing lab may even cross contaminate some items as well. But for flower it can make sense to be LOQ then be concentrated of course as it’s within the extraction. I personally don’t like to deal with moldy bio but sometimes in hemp it’s what ya gotta do. & the “just making it pass mentality” is definitely why a lot of these companies suffer from their own half assed assessment of properly cleaning up oil during post process.

Did you ever resolve this?

Pharmlabs is giving me a fail COA for Aspergillus on a quite a large batch of packaged goods.

Wondering how to remediate this now.

When you say “packaged goods,” to what exactly are you referring to? Flower? Edibles? Concentrate?

Some finished items will need to be trashed, but if it is in concentrate form, mold spores are filtered out at 0.2um, and ethanol will render spores inactive. If it’s flower, turn it into an extract to remediate. If it is a formulated final product, it gets a bit tougher, but it’s still doable.

tried using a freeze dryer?

I dont think you guys understand my question…

Pharmlabs is the only lab that is giving me a failed COA for Aspergillus.

I know for a fact, unfortunately for PharmlabsSD, that my input materials and my processes were not the source of Aspergillus.

My input materials were all COA’d…

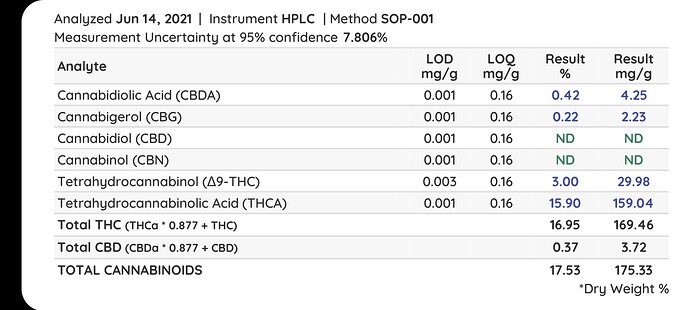

They also messed up on the potency, lol says my infused joint has 17% thc when input flower was at 28% and the hash I used was around 48%…

Hash infused prerolls packaged for sale. This was a COA test.

Just trying to mitigate the issue now. But I will inform the BCC of the obvious testing errors.

Has me puzzled.

The BCC and CDPH has to lock down on these testing labs bullshitting their COA results.

ohhhh my bad.

there was a lab in vegas a few years ago that had a similar issue.

ended up being that their method was invalid, and you had a better chance at flipping a coin.

they ended up losing their license.

sounds like some fuckery.

Sounds like your experiencing the same situation as we did. If you know your product is good scroll up and read the remediation plan “that i used” to remediate aspergillus.

Email the cdph the remediation plan, get your approval, “perform said plan” test elsewhere if it really was them(dont doubt it one bit) you should be good to go

.2 for mold cleaned up some bad stuff I had to run. I went over board and had hard time keeping it moving. But a felt tampon, that’s the ticket.

Maybe @dropwise can tell you how we did it. I am pretty sure it came back ND

I just had 20 lbs remediated for aspergillus at this place in CA. It passed compliance.

I am using him as well! Highly recommend. Very affordable per lb. Just wish he was closer.

Yeah getting up to Santa Rosa is annoying!

How do they remediate, have yall seen your product post remediation already?

Its macrowave pasteurization. RF pasteurization.

No, but I was referenced by happy clients.

Thats awesome, hope testing goes much smoother for ya from here!

We just got our flower back yesterday. I’ll report what it looks like post remediation when I stop by the warehouse on Monday. Looked good in COA pics though.

Yall are remediating mold from flower and still selling the produxt as flower or …

Selling as flower… they just found spores, you can remediate it (it’s a pasteurization method) without affecting the flower. You have to retest afterwards to confirm the absence of spores, the remediation plan also has to be approved by the state.